كيف تزيد أرباح المصنع باستخدام آلة تقطيع جذور الثوم TZQ-02؟

في صناعة معالجة الثوم، تصبح TZQ-02 آلة تقطيع جذر الثوم شائعة بشكل متزايد بين الشركات الصغيرة والمزارعين الأفراد نظرًا لكفاءتها وتصميمها موفر للطاقة وسهولة الاستخدام. إنها لا توفر العمالة فحسب، بل إنها أيضًا بأسعار معقولة. فكيف يمكن لمصانع معالجة الثوم استخدام آلة تقطيع جذر الثوم TZQ-02 لزيادة أرباحها؟

سعة عالية، انخفاض في العمالة

- السعة: 4,000–6,000 قطعة/ساعة

- الجهد: 220 فولت

- القوة: 0.5 kW

يمكن لآلة TZQ-02 تقطيع حتى 6,000 فص ثوم في الساعة، محققة كفاءة أعلى بمقدار 8–12 مرة مقارنة بالتقطيع اليدوي. بالنسبة لمصنع معالجة متوسط الحجم، فإن توفير عدة ساعات من العمل يوميًا يزيد من الربح بشكل مباشر.

تصميم موفر للطاقة، انخفاض تكاليف الكهرباء

يسمح قوة TZQ-02 البالغة 0.5 كW للمكينة بالحفاظ على استهلاك منخفض للطاقة حتى عند السعة العالية. مقارنة مع آلات التقطيع التقليدية عالية الطاقة، تشغيلها لعدة ساعات يوميًا يوفر تكاليف كهرباء كبيرة.

تصميم منخفض الطاقة وفعّال يحافظ على تكاليف التشغيل على المدى الطويل ويقلل من انبعاثات الكربون، داعمًا نهج إنتاج أكثر خضرة.

حجم مدمج، تخطيط مرن

- الأبعاد: 0.59 × 0.66 × 1.115 م

- الوزن: 50 كجم

آلة تقطيع جذور الثوم صغيرة وخفيفة الوزن، مناسبة لتخطيطات المصنع المختلفة. سواء استخدمت كوحدة مستقلة أو مدمجة في خط إنتاج، فهي تتكيف بسهولة مع العمليات الحالية، مما يقلل تكاليف التجديد.

تشغيل سهل، تقليل تكاليف التدريب

تتميز TZQ-02 بواجهة بسيطة تتطلب الحد الأدنى من التدريب للتشغيل. فهي تقلل من الأخطاء التشغيلية، وتحسن كفاءة المعالجة، وتقلل من الخسائر الناتجة عن التعامل غير السليم. بالنسبة للمصانع، يعني التشغيل السهل انخفاض تكاليف التدريب، وانخفاض أوقات التعطل، وزيادة احتمالية الربح.

المواصفات الفنية لآلة تقطيع جذر الثوم

| معامل | Value |

|---|---|

| نموذج | TZQ-02 |

| الجهد االكهربى | 220 فولت |

| قوة | 0.5 kW |

| سعة | 4,000–6,000 قطعة/ساعة |

| آلة تعبئة مسحوق الثوم | آلة تعبئة مسحوق الثوم الأوتوماتيكية 4 | 0.59 × 0.66 × 1.115 م |

| وزن | 50 كجم |

تحليل بيانات تحسين الربح

| عامل | التقطيع اليدوي | TZQ-02 آلة تقطيع جذور الثوم | تحسّн |

|---|---|---|---|

| السعة (قطع/ساعة) | 500–1,000 | 4,000–6,000 | 8–12× أعلى |

| تكلفة العمالة في اليوم | $80 | $20 | وفر تكلفة الكهرباء يوميًا من$60 |

| تكلفة الكهرباء في اليوم الواحد | $0.5 (أدوات اليد الصغيرة) | $1 | الحد الأدنى من الزيادة |

| وقت التدريب | 2–3 أيام | <1 يوم | أقصر زمن وتخفيض فترات التعطل |

| تعطل بسبب الأخطاء | عالي | منخفض | تقليل الخسائر |

| الثوم اليومي المعالج (كجم) | 50–100 | 400–600 | أكثر 5–10× |

| زيادة محتملة في الربح اليومي | – | +$50–$100 | توفير التكاليف المباشرة |

يُظهر هذا أن استخدام TZQ-02 يزيد بشكل كبير من السعة المعالجة، يقلل من مدخلات العمل، ويخفض التكاليف التشغيلية الإجمالية، مما يعزز الأرباح بشكل مباشر.

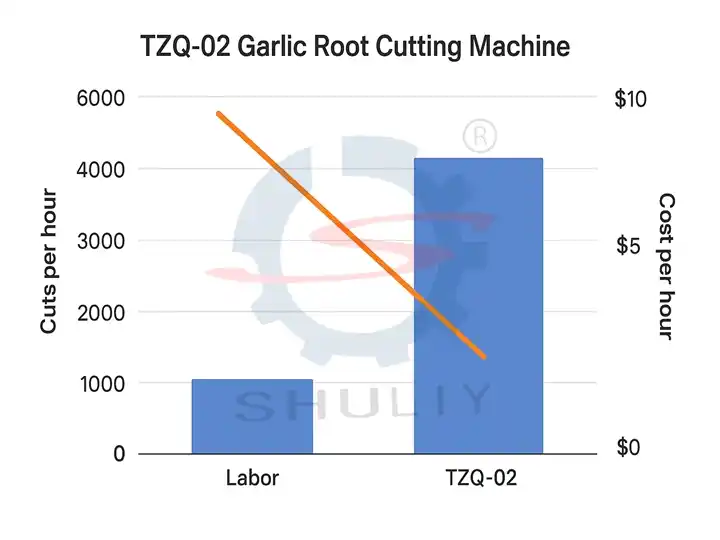

مخطط السعة والربح

المحور X: طريقة المعالجة (يدوي مقابل TZQ-02)

المحور Y 1 (يسار): القطع لكل ساعة

المحور Y 2 (يمين): التكلفة لكل ساعة ($)

من خلال تحليل المواصفات الفنية لـ TZQ-02، نرى أن هذه آلة تقطيع جذر الثوم تساعد المصانع في خفض التكاليف وتحسين الكفاءة من خلال سعة عالية، استهلاك منخفض للطاقة، تخطيط مرن، وتشغيل سهل.

عند استخدامها وفق احتياجات المصنع الفعلية، لا توفر TZQ-02 العمالة وتكاليف الكهرباء فحسب، بل تزيد أيضًا من سرعة المعالجة، مما يعظم الأرباح.

إذا كان مصنعك لا يزال يعتمد على تقطيع الثوم يدويًا، فإن TZQ-02 هي الحل المثالي لزيادة الكفاءة، تقليل التكاليف، وزيادة الأرباح.