Máquina de envasado de ajo en polvo semiautomática

La máquina de envasado de ajo en polvo semiautomática es un dispositivo utilizado para llenar con precisión el ajo en polvo en contenedores de embalaje. También es adecuada para envasar materiales en polvo en las industrias alimentaria, química, agrícola y otras.

Esta máquina utiliza un método de dosificación por tornillo, lo que garantiza una medición precisa y una fácil operación. Se puede envasar en diversas formas como bolsas, botellas y latas.

La máquina es fácil de operar, muy precisa y adaptable. Su precisión de envasado se controla dentro de ±1%, con una velocidad de envasado de 500–1500 bolsas por hora. El peso del envasado se puede ajustar entre 1 y 10 kilogramos.

Esta máquina también puede trabajar junto con máquinas de alimentación y máquinas de sellado, desempeñando un papel clave en una línea de producción de polvo de ajo.

Ventajas de la máquina de empaquetado de polvo de ajo semiautomática

- Sistema de dosificación automática: Integra tecnologías mecánicas, eléctricas, ópticas y de instrumentación, controladas por un microcontrolador para completar automáticamente el pesaje, el llenado y la corrección de errores.

- Alta velocidad de embalaje: Utiliza un sistema de alimentación por tornillo y control fotoeléctrico para una respuesta rápida y alta eficiencia.

- Alta precisión de medición: Equipado con una balanza electrónica de alto rendimiento y un motor paso a paso para un control preciso.

- Higiénico y Seguro: Hecho completamente de acero inoxidable de grado alimenticio (SUS304), fácil de limpiar, previniendo eficazmente la contaminación cruzada.

- Amplia Gama de Empaque: Ajustable a través del teclado de 1 a 10 kg, y cambiando el tornillo se adapta a diferentes tamaños.

- Amplia Compatibilidad de Materiales: Además del polvo de ajo, es adecuado para varios materiales en polvo de flujo libre.

- Corrección de Errores Inteligente: Rastrea y corrige automáticamente los errores causados por cambios en la densidad del material o fluctuaciones en el nivel del material.

- Fácil Operación: Solo se necesita colocar la bolsa manualmente; los sensores fotoeléctricos controlan la alimentación automática, manteniendo las aberturas de las bolsas ordenadas y listas para el sellado.

Composición y principio de funcionamiento de la máquina de envasado de polvo de ajo manual

Tolva de almacenamiento

Almacena polvo de ajo para asegurar una alimentación continua. Hecho de acero inoxidable, fácil de limpiar y previene el pegado.

Sistema de alimentación por tornillo

Empuja el polvo desde el embudo hasta la salida según las cantidades establecidas, con control de motor para una alimentación precisa.

Sensor de pesaje y sistema de control

Monitorea el peso de cada alimento en tiempo real utilizando una balanza electrónica, conectada a un sistema de control PLC para pesaje automático y corrección de errores.

Panel de control

Permite establecer el tamaño del paquete, la velocidad, el rango de error, etc. Tiene pantalla y botones, y algunos modelos incluyen una interfaz táctil.

Salida de descarga y boquilla de llenado

Después de pesar, el polvo se descarga aquí en contenedores colocados manualmente. La boquilla es desmontable y fácil de reemplazar para diferentes tamaños.

Estructura y carcasa

El marco de la máquina está hecho de acero inoxidable de alta calidad, robusto, duradero y cumple con los estándares de higiene alimentaria.

Materiales adecuados y escenarios de aplicación

Materiales

| Categoría de la industria | Materiales típicos |

| Industria alimentaria | Leche en polvo, almidón, polvo de condimento, y preparaciones enzimáticas |

| Industria agrícola | Alimento para animales, premix, medicina veterinaria, polvo de pesticida |

| Industria química | Aditivos, polvo detergente, polvos químicos |

Escenarios de aplicación

- Fábricas de procesamiento de alimentos

- Líneas de producción de productos agrícolas

- Estaciones de envasado de piensos o aditivos

- Talleres de envasado de productos químicos

- Plantas de fabricación de especias y condimentos

- Operaciones de embalaje de comercio electrónico

Parámetros técnicos de la máquina de envasado de polvo de ajo semiautomática

| Parámetro | Especificación |

| Suministro de energía | AC 380V, 900W |

| Rango de llenado | 1–10 kg |

| Precisión de envasado | ±1% |

| Velocidad de empaquetado | 500–1500 bolsas/hora |

| Dimensiones de la máquina | 1000 × 850 × 1850 mm |

| Peso de la máquina | 280 kg |

También ofrecemos servicios de personalización y podemos modificar la máquina según sus requisitos.

¿Cómo usar la máquina de envasado de polvo de ajo semiautomática?

- Conectar energía: Confirme que el voltaje es AC380V y verifique que la conexión a tierra esté correctamente conectada.

- Agregar material: Vierta los materiales en polvo (como polvo de ajo, leche en polvo, etc.) en la máquina de alimentación o en la tolva.

- Verificar: Asegúrese de que la tolva y el tornillo estén limpios y libres de escombros o polvo sobrante.

- Establecer parámetros: Establezca el peso de envasado (por ejemplo, 1 kg, 2 kg, etc.) / Ajuste la velocidad de envasado / Establezca el rango de error permitido (±1%)

Proceso de operación: Colocar manualmente bolsas o botellas → iniciar el envasado → pesaje y llenado automáticos → detener después del llenado → retirar las bolsas o botellas envasadas.

¿Qué máquinas se pueden usar juntas?

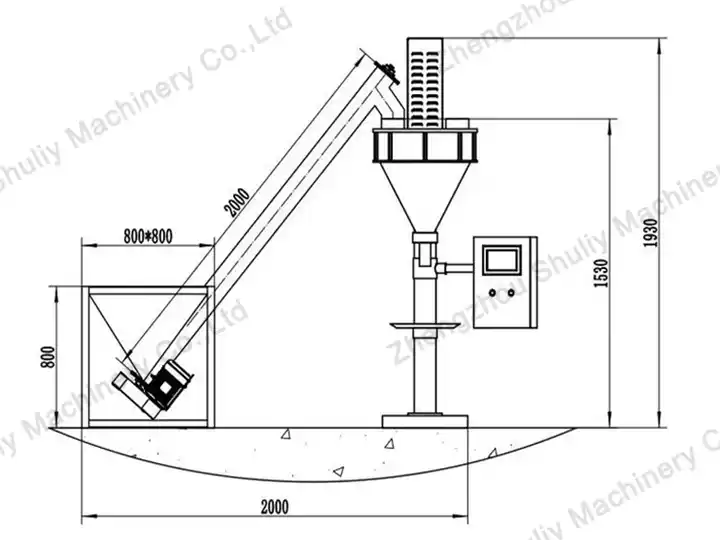

Máquina de alimentación

| Parámetro | Especificación |

| Capacidad de elevación | 1000–3000 kg/h |

| Volumen del embudo | 100–300 kg |

| Altura de alimentación | 2000 mm (personalizable) |

| Suministro de energía | AC 380V, 1100W |

| Material | Acero inoxidable |

| Peso de la máquina | 150 kg |

Máquina de sellado continuo

| Parámetro | Especificación |

| Suministro de energía | 220V 50Hz 520W |

| Ancho de sellado | Ajustable de 5 a 14 mm |

| Grosor del material de sellado | 0.03 a 0.80 mm |

| Capacidad de sellado | Hasta 55 bolsas/min (basado en bolsa de 100 mm) |

| Velocidad de sellado | 0–12 m/min |

| Rango de temperatura | 0–300°C |

| Dimensiones de la máquina | 810 × 370 × 310 mm |

| Máx. Caracteres de impresión | ≤ 39 caracteres |

| Peso | 17.5 kg |

Aplicación en la línea de producción de ajo en polvo

En la línea de producción de ajo en polvo, la máquina de envasado se utiliza generalmente como el paso final: el empaquetado.

Mantenimiento y cuidado de la máquina de envasado de polvo de ajo.

- Limpie la tolva y los tubos de alimentación después de cada jornada de trabajo.

- Revise el transportador de tornillo semanalmente en busca de desgaste o obstrucciones.

- Inspeccione el sistema de control eléctrico y el cableado mensualmente en busca de envejecimiento o aflojamiento.

- Lubrique las partes del rodamiento (si es aplicable) para extender la vida útil de la máquina.

Coopera con nosotros

Si está interesado, simplemente contáctenos para obtener detalles a través de WhatsApp directamente: https://wa.me/+8619139761487

Producto caliente

Limpieza regular

Esta máquina envasadora de polvo de ajo es completamente…

Máquina para Hacer Pasta de Jengibre y Ajo

La máquina automática para elaborar pasta de jengibre y ajo es ampliamente…

Máquina Separadora de Dientes de Ajo

La máquina separadora de dientes de ajo está diseñada para separar eficientemente…

Línea de producción de pelado de ajo | maquina procesadora de ajo

La línea de producción peladora de ajo es muy práctica…

Cortadora cóncava de raíz de ajo con doble correa

La máquina cortadora de raíces cóncavas de ajo elimina la…

Máquina de deshidratación de ajo | Horno industrial de secado de ajo

La máquina de deshidratación de ajo es una circulación de aire caliente…

Máquina de envasado al vacío de dientes de ajo

Máquina de envasado al vacío de dientes de ajo con núcleo de cobre 20L…

Cortador de raíces de cebolla

El cortador de raíces de cebolla, también llamado la…

Peladora de ajos

Una peladora de ajo está diseñada para pelar…