10 choses que vous ne saviez pas sur la machine à poudre d’ail

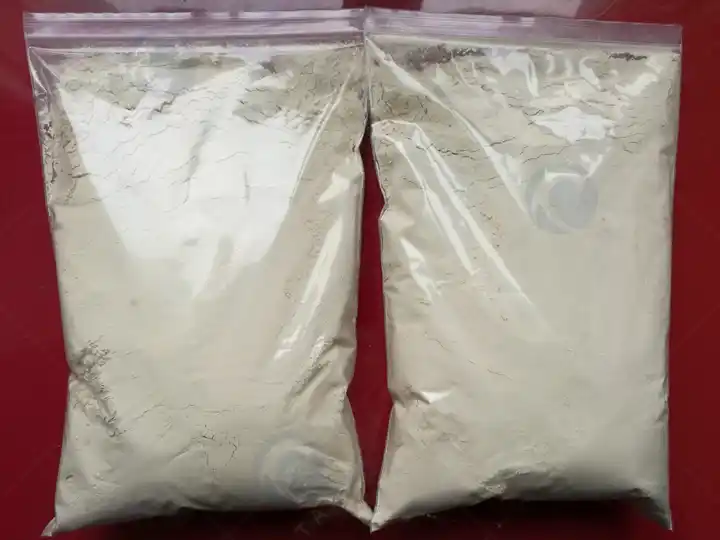

La machine à fabriquer de la poudre d'ail Shuliy peut rapidement moudre des tranches d'ail séchées en poudre fine. Selon le modèle, nous proposons des machines d'une capacité de 10–3000 kg/h. La machine produit de la poudre d'ail de 60–120 mesh, ce qui répond aux besoins de nombreuses industries.

Cet article partage 10 questions et réponses que vous ne connaissez peut-être pas sur la machine à poudre d'ail, aidant les lecteurs à mieux comprendre son fonctionnement.

1. Quels matériaux le broyeur de poudre d'ail peut-il traiter ?

Il est principalement destiné aux matériaux secs, tels que :

- tranches d'ail, de gingembre et d'oignon séchées

- céréales (riz, maïs, blé, haricots, etc.)

- herbes chinoises (baie de goji, igname, angélique, réglisse, etc.)

- épices (poivre, anis étoilé, piment, cumin, etc.)

- autres aliments secs ou matériaux chimiques

Tant que le matériau est sec et modérément dur, il peut être réduit en poudre.

2. Quels modèles Shuliy propose-t-il ?

Shuliy propose 8 modèles, de SL-15B à SL-100B. La capacité couvre 10–3000 kg/h, adaptée aux petits ateliers comme aux grandes usines alimentaires.

3. Quelle est la finesse de la poudre finie ?

Normalement 20–40 mesh. La poudre est homogène et répond aux besoins de l'industrie alimentaire et des épices.

4. De quoi la machine est-elle faite ?

Il est fabriqué en acier inoxydable 304. Il est résistant à la corrosion, facile à nettoyer, et les pièces de rechange sont faciles à remplacer avec des coûts de maintenance faibles.

5. Quelle est la capacité de chaque modèle ?

Les petits modèles (comme le SL-15B) peuvent traiter 10–50 kg par heure. Les grands modèles (comme le SL-100B) peuvent atteindre 800–3000 kg/h. Les acheteurs peuvent choisir en fonction de leurs besoins de production.

6. Qu'est-ce qui différencie Shuliy des autres marques ?

Les machines Shuliy ont une vitesse plus élevée (jusqu'à 6000 tr/min), une poudre plus fine, une plage de capacité plus large, une structure plus robuste et une durabilité plus longue.

7. Y a-t-il une limite de taille d'alimentation ?

Oui. Cela dépend du modèle. Les petits modèles permettent 6 mm, tandis que les grands modèles permettent jusqu'à 15 mm. Pas besoin de beaucoup de prétraitement, ce qui permet de gagner du temps et de la main-d'œuvre.

8. Pour quelles industries est-elle adaptée ?

Il est largement utilisé dans les usines d'épices, les ateliers de transformation alimentaire, les usines de produits agricoles, et les industries chimique et pharmaceutique. Il peut moudre l'ail, le gingembre, les céréales, les herbes, et plus encore.

9. Les matériaux riches en huile peuvent-ils être moulus directement ?

Non recommandé. L'huile provoquera adhérence et colmatage. La solution est de mélanger avec des matériaux à faible teneur en huile, en maintenant les matériaux riches en huile en dessous de 25%. Pour les matériaux très huileux, les broyer d'abord avec un concasseur avant le broyage fin.

10. Comment choisir la puissance du moteur ?

La puissance du moteur varie de 2,2 kW à 37 kW. Une puissance plus élevée signifie une capacité plus grande. Shuliy utilise des moteurs de haute qualité pour assurer un fonctionnement stable et de longue durée.

Pourquoi choisir Shuliy plutôt que d'autres marques ?

- Modèles complets, large gamme de capacités

- Vitesse élevée, broyage fin et homogène

- Machines fortes et durables

- Après-vente fiable et solutions personnalisées

- Grande expérience à l'exportation, utilisé dans de nombreux pays

Recommandation de modèles de machines à poudre d'ail

| Taper | SL-15B | SL-20B | SL-30B | SL-40B | SL-50B | SL-60B | SL-80B | SL-100B |

| Capacité de production (KG/H) | 10-50 | 60-150 | 100-300 | 160-800 | 300-1000 | 500-1500 | 600-2000 | 800-3000 |

| Taille d’alimentation (mm) | 6 | 6 | 10 | 12 | 15 | 15 | 15 | 15 |

| Finesse de concassage (Mesh) | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 |

| Puissance du moteur (KW) | 2.2 | 4 | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Vitesse de broche (R/Min) | 6000 | 4500 | 3800 | 3400 | 2900 | 2900 | 2000 | 1500 |

| Poids (kg) | 150 | 280 | 340 | 450 | 600 | 900 | 1250 | 1580 |

| Taille (MM) | 550*400*850 | 600*550*1250 | 700*600*1450 | 900*800*1550 | 1050*850*1750 | 1100*900*1880 | 1200*950*2000 | 1350*1000*2100 |

Si vous n'êtes pas sûr du quel modèle de machine à fabriquer de la poudre d'ail choisir, n'hésitez pas à nous contacter. Nous recommanderons le modèle le plus adapté en fonction de vos besoins de production.