लहसुन साफ-सफाई मशीन

10 आइटम

SL-800 लहसुन सफाई मशीन ने हंगेरियन ग्राहक को धोने की क्षमता 2000Kg/h तक बढ़ाने में मदद की

113 आइटम

SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है?

रसोई की रेसिपी - लहसुन पीसने की मशीन 3

गर्मी में लहसुन हार्वेस्टर के लिए सावधानियाँ 4

- लहसुन के सफेद करने का प्रभाव होता है 6

- लहसुन हार्वेस्टर की विशेषताएँ क्या हैं? 7

- लहसुन Separator परिचय 8

- अच्छा कृषि सहायक लहसुन हार्वेस्टर 9

- लहसुन हवा सुखाने की मशीन

- उत्पादन लाइन

0 आइटम

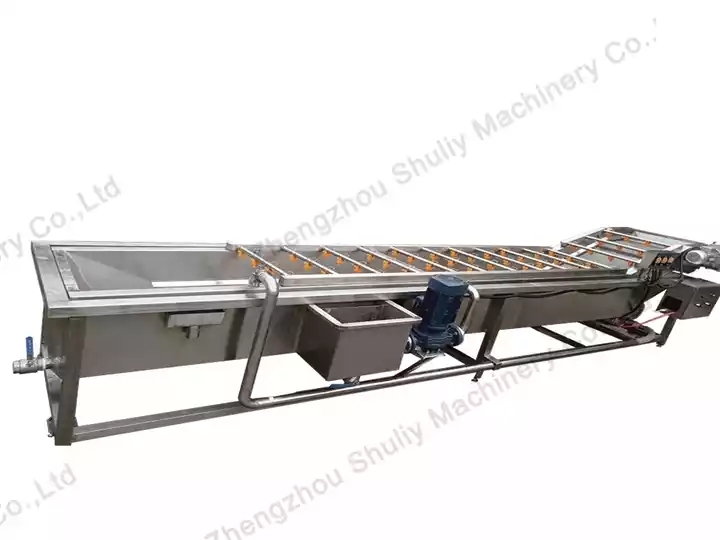

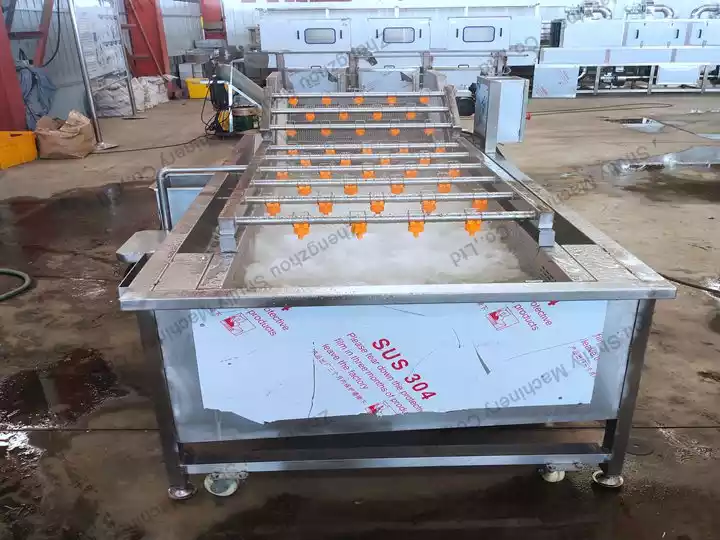

उपकरण सफाई टैंक बॉडी, उठाने वाला उपकरण, जल परिसंचरण प्रणाली, और अन्य मुख्य भागों से बना है। मशीन में पानी का पंप, एयर पंप, कन्वर्टर, हैंडव्हील स्पीड रेगुलेशन, फिल्टर टैंक, सीवेज आउटलेट, स्प्रे डिवाइस और अन्य उपकरण शामिल हैं।

SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है?

| नमूना | आकार | वज़न | शक्ति | क्षमता |

| केस | हाथ से लहसुन काटने की मशीन | 180 किलोग्राम | लहसुन हवा सुखाने की मशीन | 500 किग्रा/घंटा |

| उत्पादन लाइन | केस | 400 किलोग्राम | लहसुन पाउडर पैकिंग मशीन | स्वचालित लहसुन पाउडर पैकिंग मशीन | 800 किग्रा/घंटा |

| लहसुन हवा सुखाने की मशीन | उत्पादन लाइन | मामला | 10 आइटम | SL-800 लहसुन सफाई मशीन ने हंगेरियन ग्राहक को धोने की क्षमता 2000Kg/h तक बढ़ाने में मदद की |

| 113 आइटम | SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है? | लहसुन एयर ड्राईंग मशीन | उत्पादन लाइन | केस |

अंतिम संपादन: 2025/6/18

यह लहसुन पाउडर पैकिंग मशीन पूरी तरह से…

- लहसुन पाउडर पैकिंग मशीन | स्वचालित लहसुन पाउडर पैकिंग मशीन

- SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है?

- लहसुन पाउडर पैकिंग मशीन | स्वचालित लहसुन पाउडर पैकिंग मशीन

- लहसुन हवा सुखाने की मशीन

- उत्पादन लाइन

- मामला

- लहसुन हवा सुखाने की मशीन एक उच्च…

- लहसुन हवा सुखाने की मशीन

10 आइटम

SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है?

- लहसुन हवा सुखाने की मशीन

- उत्पादन लाइन

- केस

- SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है?

- लहसुन पाउडर पैकिंग मशीन | स्वचालित लहसुन पाउडर पैकिंग मशीन

- लहसुन हवा सुखाने की मशीन

- उत्पादन लाइन

- मामला

लहसुन एयर ड्राईंग मशीन एक उच्च…

- यह लहसुन पाउडर पैकिंग मशीन पूरी तरह से…

- लहसुन एयर ड्राईंग मशीन

- लहसुन पाउडर पैकिंग मशीन | स्वचालित लहसुन पाउडर पैकिंग मशीन

- 10 आइटम

- SL-800 लहसुन सफाई मशीन हंगेरियन ग्राहक को धोने की क्षमता 2000Kg/h तक बढ़ाने में मदद करती है

- 113 आइटम

SL-800 लहसुन सफाई मशीन का कार्य सिद्धांत क्या है?

लहसुन एयर ड्राईंग मशीन

केस

शक्ति: अनुकूलन योग्य

- प्रचार गतिविधियाँ नियमित रूप से आयोजित की जाएँगी।

- लहसुन छीलने की उत्पादन लाइन

- एक पूरी तरह से स्वचालित उच्च-उत्पादक बहुउद्देशीय लहसुन धोने की मशीन,…

- लहसुन साफ करने की मशीन 1

लहसुन साफ करने की मशीन 3

हमारे पास अन्य लहसुन प्रसंस्करण मशीनें भी हैं, जैसे लहसुन पाउडर उत्पादन लाइन, लहसुन ग्रेडिंग सॉर्टिंग मशीन, लहसुन छीलने वाली उत्पादन लाइन, आदि।

आपकी पूछताछ में आपका स्वागत है!

गर्म उत्पाद

लहसुन श्रृंखला-प्रकार छीलने वाली मशीन | वाणिज्यिक लहसुन छीलने वाली मशीन

चेन-टाइप लहसुन छीलने की मशीन विशेष रूप से डिज़ाइन की गई है…

लहसुन ग्रेडिंग मशीन

वाणिज्यिक लहसुन ग्रेडिंग मशीन सिलेंडरों का उपयोग करके वर्गीकृत करती है…

लहसुन जड़ स्टेम काटने की मशीन

लहसुन की जड़ और डंठल काटने की मशीन काटने के लिए उपयुक्त है…

लहसुन की कलियों को वैक्यूम पैक करने की मशीन

20L तांबे के कोर के साथ लहसुन की कलियाँ वैक्यूम पैकिंग मशीन…

लहसुन साफ-सफाई मशीन

एक पूर्णतः स्वचालित उच्च-उपज बहु-कार्यात्मक लहसुन धोने की मशीन,…

लहसुन स्लाइसर मशीन

यह लहसुन स्लाइसर मशीन संचालित करने में आसान है…

प्याज की जड़ काटने वाला

प्याज की जड़ काटने वाली मशीन, जिसे प्याज… कहा जाता है

लहसुन छीलने की मशीन

एक लहसुन छीलने की मशीन छीलने के लिए डिज़ाइन की गई है…