Mesin Pengklasifikasi Bawang Putih

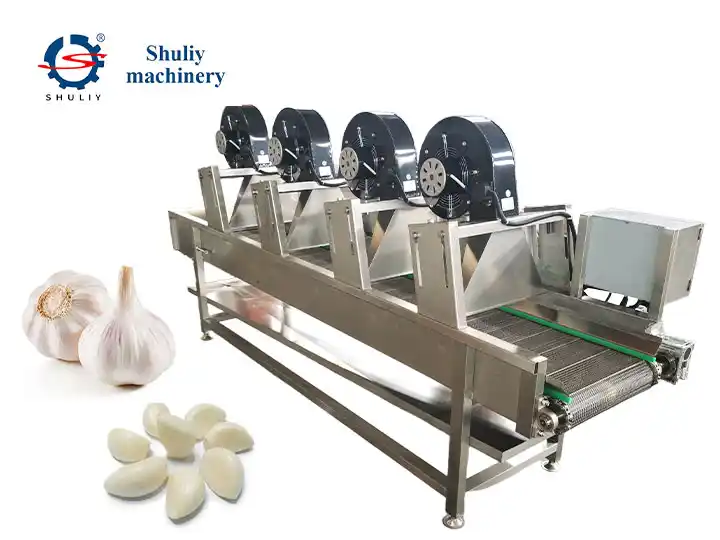

The commercial garlic grading machine uses round holes on the drum to classify garlic. It offers high sorting accuracy without damaging the bulbs, with a capacity of 3–6 tons per hour.

This machine can be used for screening and grading various materials, such as garlic, onion, apples, potatoes, and others.

The commercial garlic sorting machine is mainly composed of a hoist and a sorting machine, and the size of the sieving machine can be customized. The entire machine is made of silicone material, allowing it to directly contact the fruit without damaging it, as it is round and smooth.

This grading machine has been exported to Pakistan, Saudi Arabia, India, Thailand, Italy, and other countries.

Fitur mesin sortir bawang putih

- Mesin penyortir bawang putih komersial ini dapat mengklasifikasikan berbagai bahan bulat. Seperti kentang, kenari, hawthorn, apel, bawang bombay., dan bahan bulat lainnya atau oval.

- Besarnya penilaian dapat disesuaikan.

- Mesin Pengemasan Bubuk Bawang Putih | Mesin Pengemasan Bubuk Bawang Putih Otomatis

- Sabuk konveyor mesin ini mengadopsi pengaturan kecepatan tanpa langkah, yang dapat dengan bebas mengontrol kecepatan pengangkutan bawang putih.

- Mesin pemilah buah tipe drum ini mengadopsi penyortiran mulut lonceng, sehingga jarak lubang penyortiran menjadi lebih terstandarisasi.

- The screening part of the drum adopts silica gel to directly contact the raw materials without damaging them.

- Dengan akurasi penyortiran yang tinggi, mesin ini dapat membagi bawang putih menjadi ukuran standar dari 4,5 cm, 5,0 cm, 5,5 cm, 6,0 cm, 6,5 cm, dan di atasnya 6,5 cm. Ukuran khusus juga tersedia atas permintaan.

- Layar penyortiran terbuat dari PVC mesh, dan meja pemberian makanan dilengkapi dengan sikat untuk memastikan bawang putih tidak rusak.

- Mesin penyortir bawang putih menawarkan beberapa tingkat penyortiran. Tergantung pada skala pemrosesan, Anda bisa memilih 2, 3, 4, atau 5 tingkat, yang sangat meningkatkan efisiensi pemrosesan bawang putih primer.

Prinsip kerja mesin pemeringkat bawang putih komersial

The machine uses a lifting conveyor to feed garlic into the grading machine. The garlic moves along the conveyor into a grading drum with round holes of increasing sizes. During sorting, garlic falls gradually into the corresponding collection containers by size and then passes through the discharge outlet into packing bags, achieving automated grading and collection.

Structure of the garlic sorting machine

The garlic sorting machine mainly consists of a lifting system, a conveying system, a grading device, a collection system, and a control system.

Lifting system

Machine: Belt elevator

Function: Lifts garlic from the ground or feed inlet to the working height of the grading machine, ensuring continuous feeding

Conveying system

Machine: Chain conveyor

Function: Evenly transports garlic to the grading drum or grading wheel

Grading device

Machine: Round-hole drum sieve

Function: Holes increase in size from small to large, sorting garlic by size

Collection system

Machine: Hopper

Function: Collects garlic of different sizes separately

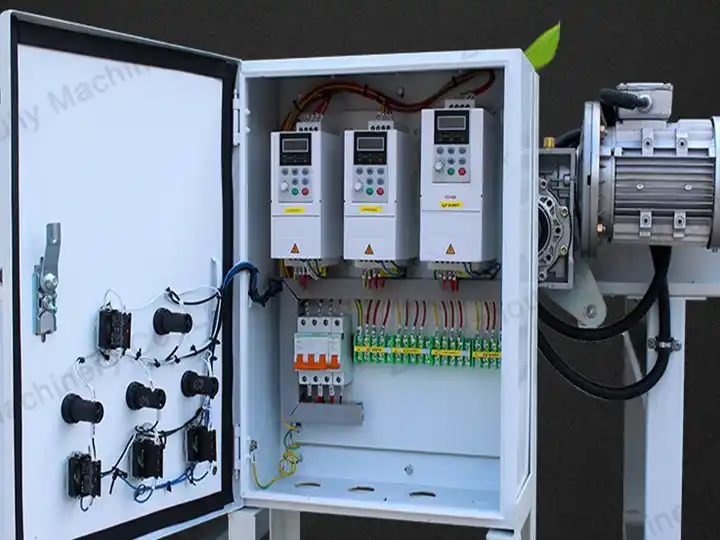

Control system

Machine: PLC intelligent control box

Function: Controls the entire machine operation, including motor start/stop and conveyor speed adjustment

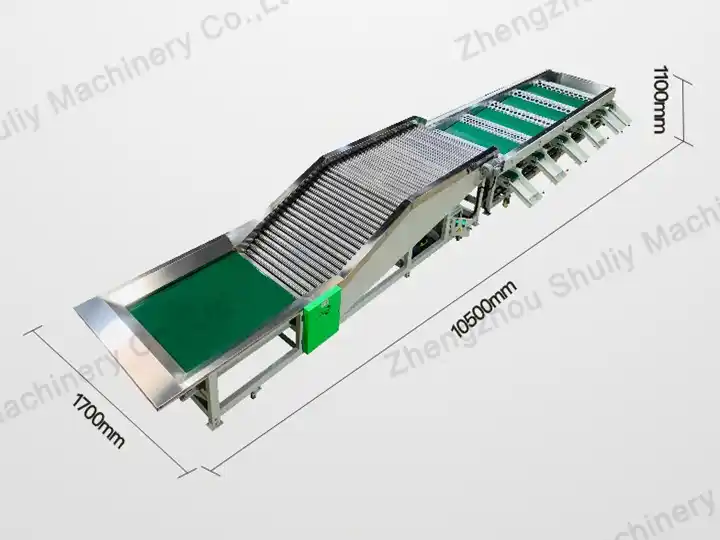

Parameter mesin grader bawang putih komersial

| Model | SL-3 | SL-4 | SL-5 |

| Kekuatan | 1.1kw | 1.1kw | 1.1kw |

| Voltase | 380V | 380V | 380V |

| Kapasitas | 1-2t/h | 3-4t/jam | 5-6t/h |

| Ukuran | 3505*955*925mm | 8000*1400*800mm | 10500*1700*1100mm |

If you have more requirements, we can customize the machine according to your needs, such as power voltage, plug type, sieve hole size, or more grading levels. You are welcome to contact us for consultation.

Garlic grading machine ROI analysis

After purchasing a garlic grading machine, it is important to consider its return on investment (ROI). The ROI can be evaluated from several aspects: cost input, increased output, labor savings, and added product value. Here, we assume a small to medium-sized garlic paste processing factory with a daily processing capacity of about 4 tons. The above prices are for reference only and do not reflect actual purchase costs.

| Item | Value |

|---|---|

| Equipment investment cost | $10,000 |

| Installation and commissioning | $1,000 |

| Daily processing capacity | 4 tons |

| Garlic price | $1,000/ton (raw material cost, not profit, used for output calculation) |

| Increased output efficiency | 5% |

| Labor savings | 2 people × $10/day × 25 days/month = $500/month |

| Operating cost | $100/day × 25 days/month = $2,500/month |

Revenue from increased output

- Original daily output value: 4 tons × $1,000 = $4,000

- Efficiency increase 5% → Additional output value: $4,000 × 5% = $200/day

- Monthly added value (25 days): $200 × 25 = $5,000

Labor savings

- Monthly labor cost savings: $500

Monthly net profit

- Monthly added value + labor savings – operating cost

- $5,000 + $500 – $2,500 = $3,000/month

Investment payback period

- Total investment: $10,000 + $1,000 = $11,000

- Monthly net profit: $3,000

- Payback period = $11,000 ÷ $3,000 ≈ 3.7 months

Conclusion

Under these assumptions, the garlic grading machine can pay back in about 4 months. After that, the increased output and labor savings almost entirely convert to profit, giving a very high return on investment.

Garlic deep processing

Shuliy has over ten years of production and sales experience and offers a full range of garlic processing machines, including garlic clove splitters, garlic peelers, garlic washers, and more. We can also provide complete solutions for garlic powder and garlic paste production lines. You are welcome to contact us through the pop-up chat for more information.

Produk Panas

Mesin Penggiling Bubuk Bawang Putih

Mesin penggiling bubuk bawang putih digunakan untuk menggiling…

Mesin Pengemasan Bubuk Bawang Putih Semi-Otomatis

Mesin pengemas bubuk bawang putih semi-otomatis digunakan…

Mesin Pengupas Bawang Putih

Mesin pengupas bawang putih dirancang untuk mengupas…

Mesin Pengklasifikasi Bawang Putih

Mesin penggolong bawang putih komersial menggunakan silinder untuk mengklasifikasi…

Mesin Pengiris Bawang Putih

Mesin pemotong bawang putih ini mudah dioperasikan…

Mesin Penanaman Bawang Putih

Mesin penanam bawang putih adalah alat pertanian…

Mesin Pengering Udara Bawang Putih

Mesin pengering udara bawang putih adalah alat yang sangat…

Mesin Pengering Bawang Putih | Pengering Sabuk Bawang Putih

Mesin pengering bawang putih umumnya dikenal sebagai…

Mesin Pembersih Bawang Putih

Mesin pencuci bawang putih multifungsi hasil tinggi sepenuhnya otomatis,…