Mesin Pengering Bawang Putih | Pengering Sabuk Bawang Putih

The garlic drying machine, commonly known as a continuous food dehydrator or continuous belt dryer, can be used for dehydrating garlic slices. The dried garlic slices obtained can be ground into garlic powder for secondary processing.

This drying machine features fast drying speed and uniform drying performance, and it is widely used in the food, pharmaceutical, chemical, construction, and electronics industries.

Pengering bawang putih otomatis penuh ini sangat cocok untuk mengeringkan bahan berbentuk irisan, strip, dan butiran dengan kadar air tinggi yang sensitif terhadap suhu tinggi, seperti irisan bawang putih dan irisan jahe.

Shuliy offers seven types of garlic drying machines, with drying lengths ranging from 8 to 20 meters to meet different production requirements. It can handle material thicknesses of 10–80 mm, ensuring uniform heating of garlic slices. The average drying time ranges from 0.2 to 3 hours, providing fast and efficient drying. Compared to conventional belt dryers, Shuliy’s machines save nearly 50% of the processing time.

Ruang lingkup aplikasi mesin pengering bawang putih

The automatic garlic dehydrator adopts a steel mesh conveyor design and can be widely used for drying and sterilizing various foods, including snacks, agricultural products, fish fillets, meat slices, bean products, instant noodles, fast food, tea, Chinese medicinal materials, fruits and vegetables, and seasoning powders. It is suitable for granular, sliced, and strip-shaped materials.

This machine is applied in fields such as food processing, agricultural product storage, seasoning production, healthcare, and international trade.

Mesin pengering bawang putih Fitur struktural

- 10 item: 1,2–2,2 m, panjang pengeringan: 8–20 m, cocok untuk berbagai kapasitas produksi.

- Ketebalan bahan: 10–80 mm, mampu mengeringkan berbagai bahan.

- Suhu pengeringan: 50–140°C, tekanan uap: 0,2–0,8 MPa.

- Kapasitas pengeringan: 60–600 kg/jam, dengan waktu pengeringan singkat hingga 0,2 jam, memastikan operasi cepat dan efisien.

- Konsumsi uap: 120–1200 kg/jam, dengan efisiensi termal tinggi.

- Daya total: 11,4–36,8 kW, memastikan operasi berdaya tinggi secara terus-menerus.

- Konstruksi kokoh: Berat mesin 4500–14000 kg, cocok untuk penggunaan berat jangka panjang.

- Made of high-strength steel, wear-resistant, pressure-resistant, and corrosion-resistant.

- Aplikasi luas: Cocok untuk mengeringkan kayu, biji-bijian, pelet, biomassa, dan bahan lain, dengan kontrol suhu dan intensitas pengeringan yang tepat.

Struktur dari mesin pengering bawang putih

- Sistem pemberian bahan: Bahan didistribusikan secara merata ke atas sabuk konveyor setelah dimasukkan. Ketebalan lapisan dapat disesuaikan: 10–80 mm.

- Sistem sabuk konveyor: Lebar sabuk: 1,2–2,2 m, kecepatan dapat disesuaikan, biasanya 3–5 lapisan. Terbuat dari jaring stainless steel berkualitas makanan untuk pemberian bahan secara terus-menerus ke area pengeringan.

- Ruang pengering: Panjang pengeringan: 8–20 m, suhu kerja: 50–140°C, tekanan uap: 0,2–0,8 MPa. Bahan dipanaskan oleh udara panas atau uap untuk penguapan kelembapan.

- Sistem pemanasan: Memberikan energi panas. Pilihan: uap, tungku udara panas, pemanasan listrik, atau pemanasan gas.

- Sistem sirkulasi udara & exhaust: Sirkulasi udara panas dengan exhaust kelembapan, menjaga suhu ruang tetap stabil. Volume udara dapat disesuaikan, laju exhaust tergantung pada kelembapan bahan.

- Sistem transmisi & kontrol: Daya total: 11,4–36,8 kW. Konveyor digerakkan oleh motor, dengan kontrol otomatis PLC untuk suhu, kecepatan, dan kelembapan.

Technical Specification

| Model | SL-1.2-8 | SL-1.2-10 | SL-1.6-8 | SL-1.6-10 | SL-2-8 | SL-2-10 | SL-2-20 |

| Satuan | 4 | 5 | 4 | 5 | 4 | 5 | 10 |

| Lebar sabuk(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

| Panjang pengering(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 |

| Ketebalan material(mm) | 10-80 | ||||||

| Suhu layanan(°C) | 50-140 | ||||||

| Tekanan uap(Mpa) | 0.2-0.8 | ||||||

| Konsumsi uap(kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 |

| Waktu pengeringan(jam) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 |

| Intensitas pengeringan(kg/h) | 60-160 | 820-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 |

| Total daya | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 |

| Panjang(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Lebar(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Tinggi(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 |

| Berat total(kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 |

The above chart presents 7 of our garlic dehydrator machine models. The belt width and length can be customized according to the customers’ needs.

Apa keuntungan luar biasa dari pengering irisan bawang putih otomatis?

- Mesin dehidrator bawang putih dapat berupa jenis sabuk jaring multi-lapis, dengan kontrol suhu otomatis, penyebaran bahan otomatis, dan produksi berkelanjutan.

- All parts in contact with the product are made of food-grade stainless steel, ensuring hygienic drying.

- The garlic slice belt dryer is a newly developed type of equipment on the basis of the traditional belt dryer, with high energy utilization efficiency.

- Berbagai macam aplikasi. Pengering irisan bawang putih cocok untuk dehidrasi dan pengeringan berbagai sayuran dan buah-buahan daerah dan musiman. Seperti irisan bawang putih, labu kuning, konjak, lobak putih, ubi, rebung, dll.

- Layanan penyesuaian yang tersedia untuk memenuhi kebutuhan pemrosesan yang berbeda sesuai dengan investasi yang berbeda.

How does a garlic drying machine dry garlic slices?

Below, we will take our machine as an example to demonstrate the garlic slice drying process.

Breaks whole garlic bulbs into individual cloves.

Peels garlic cloves with a peeling rate of over 95%, without damaging the garlic.

Removes spoiled cloves and washes garlic in bulk using bubble cleaning.

Slice the garlic into pieces with a thickness of 2–3 mm.

Garlic drying machine

Dry the garlic slices for further processing or storage.

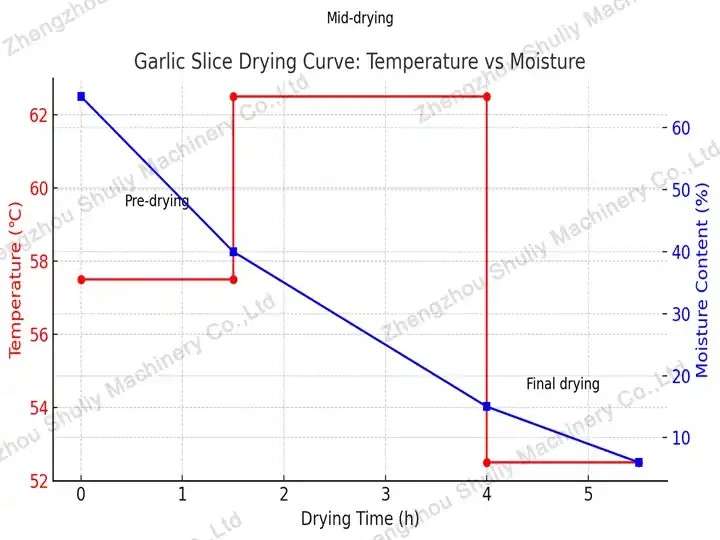

Kontrol Suhu (Referensi)

- Awal: 55–60°C → Cepat menghilangkan kelembapan permukaan

- Tengah: 60–65°C → Pengeringan stabil

- Akhir: 50–55°C → Penghilangan kelembapan pada suhu rendah untuk mencegah kekuningan

Temperature control is related to the thickness of your material layer. The above is only a reference. The exact temperature and humidity should be adjusted according to your specific situation. If you are not sure how to set it up, we can provide support and help you complete the production

Jenis lain dari mesin dehidrasi bawang putih

Berikut adalah jenis lain dari oven pengering bawang putih industri, dengan sejumlah troli dan baki untuk pengeringan batch.

If you want to know more about the garlic drying room, you can also contact us for more information.

Produk Panas

Mesin Pengiris Bawang Putih

Pemotong bawang putih berkinerja tinggi, multifungsi, kontrol mudah…

Pemotong Akar Bawang

Pemotong akar bawang, juga disebut sebagai bawang…

Mesin Pengupas Bawang Putih

Mesin pengupas bawang putih dirancang untuk mengupas…

Mesin Pemotong Cincin Bawang

Mesin pemotong cincin bawang, juga disebut…

Mesin Pembersih Bawang Putih

Mesin pencuci bawang putih multifungsi hasil tinggi sepenuhnya otomatis,…

Mesin Pengemasan Vakum Siung Bawang Putih

Mesin vakum kemasan putih bawang dengan inti tembaga 20L…

Mesin Panen Bawang Putih Secara Manual

Mesin panen bawang putih membantu petani memanen bawang putih…

Mesin Pengiris Bawang Putih

Mesin pemotong bawang putih ini mudah dioperasikan…

Mesin Pengering Bawang Putih | Pengering Sabuk Bawang Putih

Mesin pengering bawang putih umumnya dikenal sebagai…