The commercial garlic grading machine uses round holes on the drum to classify garlic. It offers high sorting accuracy without damaging the bulbs, with a capacity of 3–6 tons per hour.

This machine can be used for screening and grading various materials, such as garlic, onion, apples, potatoes, and others.

The commercial garlic sorting machine is mainly composed of a hoist and a sorting machine, and the size of the sieving machine can be customized. The entire machine is made of silicone material, allowing it to directly contact the fruit without damaging it, as it is round and smooth.

This grading machine has been exported to Pakistan, Saudi Arabia, India, Thailand, Italy, and other countries.

ニンニク選別機の特徴

- この商業用ニンニク選別機は、さまざまな丸い材料を分類できます。例えば ジャガイモ、クルミ、サンザシ、リンゴ、タマネギ, およびその他の丸いまたは楕円形の材料。

- グレーディングのサイズはカスタマイズできます。

- Shuliy包装機は、自動計量、袋形成、充填、封印、切断、故障検出とアラーム、コーディング/インクジェット印刷を提供します。また、窒素充填、除塵、自動供給システムなどのカスタマイズ可能な追加機能もサポートしています。

- 機械のコンベアベルトは無段階速度調整を採用しており、ニンニクの搬送速度を自由に制御できます。

- このドラム式果物選別機はベルマウス選別を採用しており、選別穴の間隔がより標準化されています。

- The screening part of the drum adopts silica gel to directly contact the raw materials without damaging them.

- 高い選別精度を持ち、機械は標準サイズのニンニクにグレード分けできます。 4.5cm、5.0cm、5.5cm、6.0cm、6.5cm、 以上 6.5cm. カスタムサイズもリクエストに応じて利用可能です。

- グレーディングスクリーンは PVC メッシュと給餌台にはブラシが装備されており、ニンニクが損傷しないようにしています。

- ニンニクのグレーディングマシンは複数のグレーディングレベルを提供します。処理規模に応じて選択できます。 2、3、4、または 5 等級により、一次ニンニク処理の効率が大幅に向上します。

業務用ニンニク選別機の動作原理

The machine uses a lifting conveyor to feed garlic into the grading machine. The garlic moves along the conveyor into a grading drum with round holes of increasing sizes. During sorting, garlic falls gradually into the corresponding collection containers by size and then passes through the discharge outlet into packing bags, achieving automated grading and collection.

Structure of the garlic sorting machine

The garlic sorting machine mainly consists of a lifting system, a conveying system, a grading device, a collection system, and a control system.

Lifting system

Machine: Belt elevator

Function: Lifts garlic from the ground or feed inlet to the working height of the grading machine, ensuring continuous feeding

Conveying system

Machine: Chain conveyor

Function: Evenly transports garlic to the grading drum or grading wheel

Grading device

Machine: Round-hole drum sieve

Function: Holes increase in size from small to large, sorting garlic by size

Collection system

Machine: Hopper

Function: Collects garlic of different sizes separately

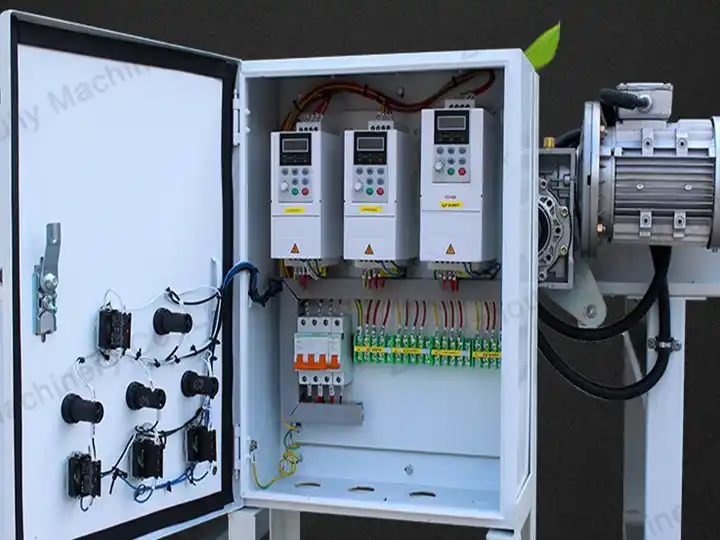

Control system

Machine: PLC intelligent control box

Function: Controls the entire machine operation, including motor start/stop and conveyor speed adjustment

商用ニンニク選別機パラメータ

| モデル | SL-3 | SL-4 | SL-5 |

| 力 | 1.1kw | 1.1kw | 1.1kw |

| 電圧 | 380V | 380V | 380V |

| 容量 | 1-2t/h | 3~4t/h | 5-6t/h |

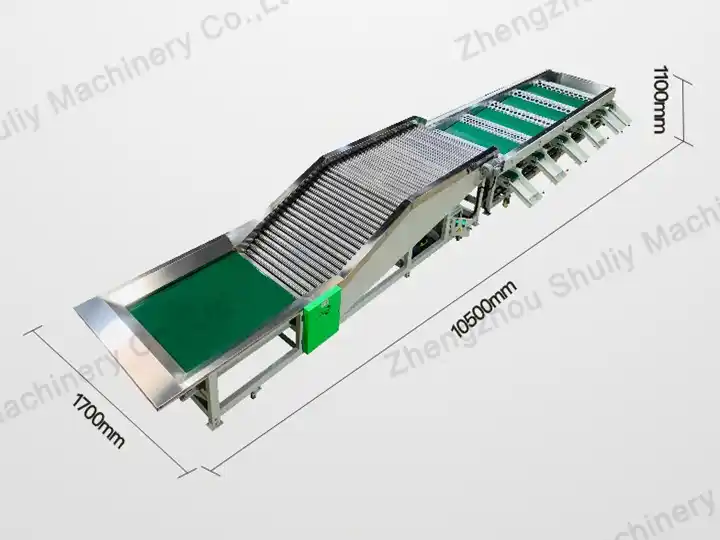

| サイズ | 3505*955*925mm | 8000*1400*800mm | 10500*1700*1100mm |

If you have more requirements, we can customize the machine according to your needs, such as power voltage, plug type, sieve hole size, or more grading levels. You are welcome to contact us for consultation.

Garlic grading machine ROI analysis

After purchasing a garlic grading machine, it is important to consider its return on investment (ROI). The ROI can be evaluated from several aspects: cost input, increased output, labor savings, and added product value. Here, we assume a small to medium-sized garlic paste processing factory with a daily processing capacity of about 4 tons. The above prices are for reference only and do not reflect actual purchase costs.

| Item | Value |

|---|---|

| Equipment investment cost | $10,000 |

| Installation and commissioning | $1,000 |

| Daily processing capacity | 4 tons |

| Garlic price | $1,000/ton (raw material cost, not profit, used for output calculation) |

| Increased output efficiency | 5% |

| Labor savings | 2 people × $10/day × 25 days/month = $500/month |

| Operating cost | $100/day × 25 days/month = $2,500/month |

Revenue from increased output

- Original daily output value: 4 tons × $1,000 = $4,000

- Efficiency increase 5% → Additional output value: $4,000 × 5% = $200/day

- Monthly added value (25 days): $200 × 25 = $5,000

Labor savings

- Monthly labor cost savings: $500

Monthly net profit

- Monthly added value + labor savings – operating cost

- $5,000 + $500 – $2,500 = $3,000/month

Investment payback period

- Total investment: $10,000 + $1,000 = $11,000

- Monthly net profit: $3,000

- Payback period = $11,000 ÷ $3,000 ≈ 3.7 months

Conclusion

Under these assumptions, the garlic grading machine can pay back in about 4 months. After that, the increased output and labor savings almost entirely convert to profit, giving a very high return on investment.

Garlic deep processing

Shuliy has over ten years of production and sales experience and offers a full range of garlic processing machines, including garlic clove splitters, garlic peelers, garlic washers, and more. We can also provide complete solutions for garlic powder and garlic paste production lines. You are welcome to contact us through the pop-up chat for more information.

人気商品

ダブルベルトニンニク根凹面切断機

ニンニクの凹根切断機は、ニンニクの根を除去します。

機械の能力に応じて袋と製品を積載し、過負荷をかけないでください。

このにんにくパウダー包装機は完全に…

タマネギの根切り器

タマネギの根切り器は、別名タマネギ…

ニンニクスライサー機

このガーリックスライサーマシンは操作が簡単です…

オニオンリングカッティングマシン

玉ねぎリングカッティングマシン、または…

ニンニク乾燥機 | ニンニクベルト乾燥機

ニンニク脱水機は一般に…

セミオートマチックにんにくパウダー包装機

半自動にんにく粉末包装機は…に使用されます

にんにくクローブ真空包装機

20L銅芯付きにんにくクローブ真空包装機…

ニンニクチェーンタイプの皮むき機 | 商業用ニンニクピーラー

チェーン式ニンニク皮むき機は特別に設計されて…