ガーリックパウダー包装機 | 自動ガーリックパウダー包装機

販売中の最新モデルの自動ニンニクパウダー包装機

ガーリックエアドライヤーは非常に…

ガーリックパウダー包装機 | 自動ガーリックパウダー包装機

完全自動の高収率多機能ガーリック洗浄機、…

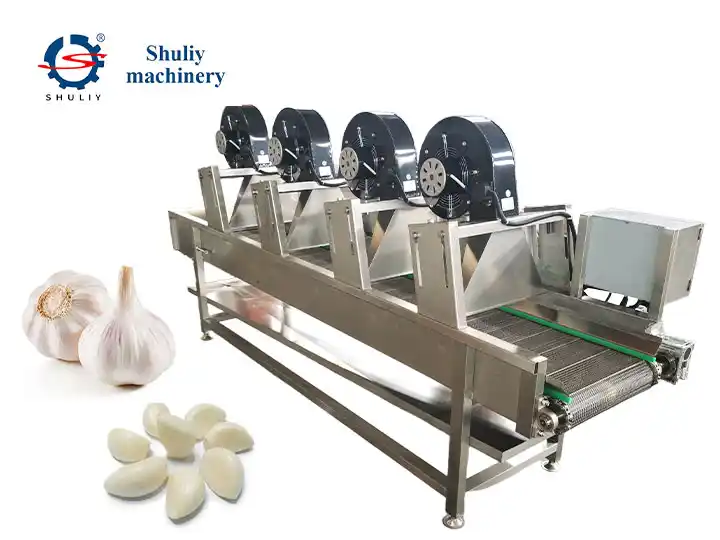

ニンニクの空気乾燥機

10アイテム

- 電力:カスタマイズ可能 ニンニク洗浄機は、水浴泡洗浄を通じて手動洗浄動作を模倣します。

- スムーズに輸送され、速度調整可能で、ニンニクに対する接触、衝撃、傷、その他の損傷を効果的に回避でき、作業効率を向上させ、手作業を機械化処理に変更します。このニンニク洗浄機は効率的で迅速です。出力は最大2000 kg/hを清掃でき、多くの大規模農場や食品工場の選択肢です。この機械はアメリカ、オーストラリア、ロシアなどの国に輸出されました。

- ニンニククリーナーは多機能です。ニンニクを洗浄するだけでなく、さまざまな新鮮な果物、野菜、塩漬け野菜、キノコ、海産物も洗浄でき、洗浄された製品に損傷を与えることはありません。環境に優しく、省エネルギーです。循環水システムは水を節約するために使用でき、水循環ろ過システムや食品グレードのステンレス鋼材料により、排出される汚水は非常に環境に優しいものになります。

- ニンニクスライサー 高性能、多機能、簡単操作の…このガーリックパウダー包装機は完全に…

- にんにく洗浄機 8 ガーリックパウダー包装機 | 自動ガーリックパウダー包装機

なぜShuliyのベストセラーのガーリックエアドライヤーを選ぶのか?

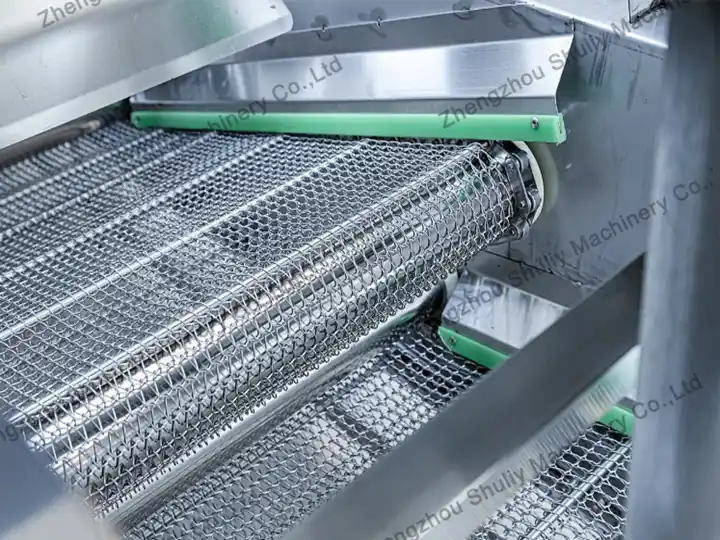

供給コンベア:機械は高品質のSUS304ステンレス鋼メッシュベルトを採用しており、優れた耐食性と耐錆性を提供します。より大きく厚いチェーンメッシュを備えたアップグレードオプションが利用可能で、従来のメッシュベルトよりも大幅に長い寿命を提供します。ジャミングや破損なしに、スムーズで安定した動作を保証します。メッシュベルトの長さと穴のサイズは、処理ニーズに応じてカスタマイズできます。連続生産ラインに適しています。

高圧ブロワー:機械には、当社が開発した特別にカスタマイズされた大容量マルチブレードブロワーが装備されています。低消費電力、強力な気流、低ノイズ、高風圧を特徴とし、死角のない360度均一乾燥を保証します。純銅コイルの使用は、長持ちする安定した連続したパフォーマンスを保証します。

コントロールパネル:可変周波数ドライブ(VFD)を装備しており、速度調整が可能で、機械の動作速度を正確に制御でき、顧客は生産ペースを簡単に管理できます。

機械フレームとハウジング:機械全体が食品グレードの304ステンレス鋼で作られており、耐久性があり、耐食性があり、食品加工衛生基準に完全に準拠しています。

アフターサービス:専門のアフターサービスチームが24時間迅速に対応します。1年間の無料サービスと生涯メンテナンス(部品費用のみ請求)。設置と試運転は、オンサイトでの実践的な操作とメンテナンスに関する無料トレーニングとともに完了します。エンジニアは常にさまざまな技術サービスを提供できます。

寸法:650*1050*1750mm

| モデル | ニンニクパウダー包装機の販売 | 中国のニンニクパウダー包装機 | 力 | 容量 |

| ニンニクパウダー包装 | 3000*1200ニンニクスライサー 高性能、多機能、簡単に操作できる… | 400 | ガーリックパウダー包装機 | 自動ガーリックパウダー包装機 | 500kg/h |

| このガーリックパウダー包装機は完全に… | 4000*1200ニンニクスライサー 高性能、多機能、簡単に操作できる… | 600 | ガーリックパウダー包装機 | 自動ガーリックパウダー包装機 | 800kg/h |

| SL-5000 | 5000*1200ニンニクスライサー 高性能、多機能、簡単に操作できる… | 800 | 13.6kw | 1000kg/h |

| SL-6000 | 6000*1200ニンニクスライサー 高性能、多機能、簡単に操作できる… | 1300 | 13.6kw | SL-800 ニンニク洗浄機は、ハンガリーの顧客が洗浄能力を2000Kg/hに増加させるのを助けます |

10アイテム

ガーリックパウダー包装機は、ガーリックパウダー専用に設計された高効率の自動機械です。通常、垂直構造を使用します(

- 10アイテム 呼ばれる

- 2000Kg/h — 玉ねぎ、生姜、唐辛子などのさまざまな製品を空気乾燥するのに適しています。

- 食品加工工場 — さまざまな野菜や果物を前処理して、保存期間を延ばすため。

- 伝統的な中国医学の加工 — 乾燥効率を向上させるために薬草を空気乾燥する。

- 保管と輸送の段階 — 腐敗やカビのリスクを減らすために果物や野菜を前処理する。

- 連続生産ライン — 大規模な生産需要に適しており、均一で効率的な乾燥を保証します。

ニンニク空気乾燥機の維持方法

定期清掃

- 使用後は、特にコンベヤーベルトと空気ダクトを清掃して、詰まりを防ぎます。

- ファンブレード、フィルター、電気制御ボックスを定期的に清掃して、良好な換気を維持し、ほこりの蓄積を避けます。

電気システムのチェック

- 電源ケーブルと制御パネルを定期的に点検し、緩み、劣化、短絡がないか確認します。

- 制御システムを乾燥した状態に保ち、湿気による故障を防ぎます。

可動部品の潤滑

- 摩擦と摩耗を減らし、機械の寿命を延ばすために、チェーンやベアリングなどの可動部品を定期的に潤滑してください。

ファン動作の監視

- ファンが異常な音や振動なしにスムーズに動作していることを確認してください。

- 不具合が発生した場合は、モーター部品やファンブレードの緩みや損傷を確認してください。

ja

- 運転中にネジが緩むことがありますので、構造の安定性を確保するために定期的に点検し、締め直してください。

摩耗部品の交換

- 使用頻度やメーカーの推奨に基づいて、ベルト、ファンブレード、モーターなどの消耗部品を適時に交換してください。

メンテナンスログ

- 将来のトラブルシューティングや機械管理を容易にするために、日付、メンテナンスタスク、遭遇した問題を含む詳細なメンテナンス記録を保持してください。

ご要望がございましたら、できるだけ早くお気軽にお問い合わせください!

人気商品

ニンニク乾燥機 | 産業用ニンニク乾燥オーブン

ニンニク乾燥機はホットエア循環…

オニオンリングカッティングマシン

玉ねぎリングカッティングマシン、または…

にんにく洗浄機

全自動高生産性多機能にんにく洗浄機、…

ダブルベルトニンニク根凹面切断機

ニンニクの凹根切断機は、ニンニクの根を除去します。

機械の能力に応じて袋と製品を積載し、過負荷をかけないでください。

このにんにくパウダー包装機は完全に…

にんにく等級付け機械

業務用ニンニク選別機はシリンダーを使用して分類します…

ニンニクの皮むき機

にんにく皮むき機は皮をむくために設計されています…

ニンニクスライサー機

このガーリックスライサーマシンは操作が簡単です…

ニンニクの皮むき生産ライン |ニンニク加工機

にんにく皮むき生産ラインは非常に実用的です…