にんにく粉末はどのように製造されるか?

ニンニク粉は世界中で人気の自然調味料です。新鮮なニンニクの独特な香りと風味を保ちつつ、保存や輸送も容易です。食品、調味料、健康製品、さらには動物飼料にも広く使用されています。

では、どうやって新鮮なニンニクを細かい白いニンニク粉に変えるのか? 今日は、最新のニンニク粉生産ラインの内部を案内し、全工程を見ていきます。

原料選定

ニンニク粉の品質は原料から始まります。新鮮で清潔、カビのないニンニクが高品質なニンニク粉を作る鍵です。良質な原料は純粋な風味を保証し、不純物や廃棄物の削減に役立ちます。

クローブの分離と皮むき

伝統的な手動のニンニクの皮むきは時間と労力がかかります。現代のニンニク粉生産ラインでは、この工程は完全に自動化されており、ニンニククローブ分離器とエアプレスピーラーを使用しています。

手動でこすりながら、丸ごとのニンニク球を個々のクローブに分離します。

空気圧ピーリング技術を使用し、皮を傷つけずに剥がします。水を使わずにさまざまなサイズのニンニクに対応します。

ニンニク洗浄

皮むき後、ニンニククローブはバブル洗浄機に入ります。この機械は水流と泡立ちを利用して手洗いを模倣し、汚れや不純物を効果的に除去します。

全機械は食品グレードのステンレス鋼 SUS304 で作られています。洗浄工程は優しく、速度調整が可能で、ニンニクのクローブを傷つけることはありません。

スライスと乾燥

洗浄されたニンニクは、ニンニクスライサーを使って均一な薄片にスライスされます。

次に、スライスは多層メッシュベルトの脱水機または乾燥室に入り、温度と湿度を制御しながら乾燥されます。

- 加熱は電気、ガス、またはバイオマスペレットで行えます。

- スマート制御システムが温度と時間を自動調整します。

- 乾燥ニンニクスライスは自然な色で、焦げず、含水率は 5%.

粉砕

乾燥したニンニクスライスは、ニンニク粉粉砕機で粉砕されます。

機械は回転歯板と固定歯板の相対運動を利用して、ニンニクを素早く粉末にします。細かさは調整可能(20–120メッシュ)です。低騒音で、粉塵除去システムも備えており、粉末は均一で清潔、安全です。

10アイテム

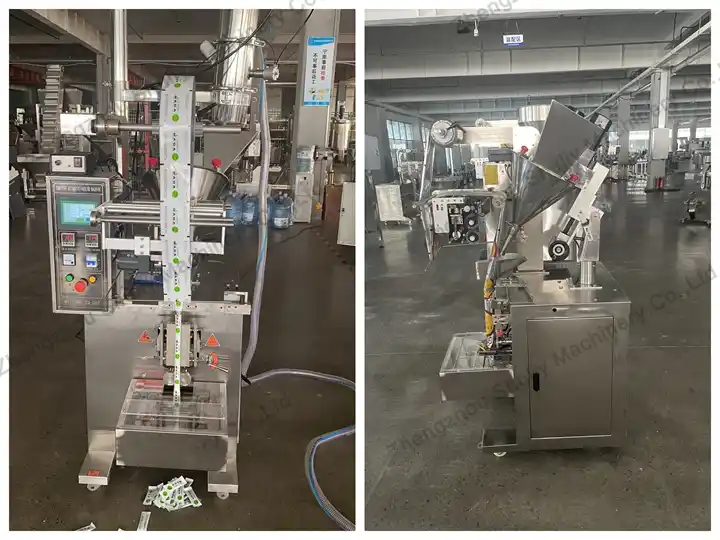

最終的に、ニンニク粉は半自動または完全自動の包装機に送られます。

機械は自動的に計量、充填、封印、搬送が可能です。パッケージのサイズや袋の種類は、市場のニーズに合わせてカスタマイズできます。例えば、バルクバッグ、スパイス瓶、輸出用パッケージなどです。

品質管理と検査

ニンニク粉の生産過程では、操作者が定期的に粉の細かさ、色、水分、風味を確認します。

適格なニンニク粉は、淡黄色からオフホワイトで、テクスチャーが均一で、異臭がなく、保存性も良好です。

高品質なニンニク粉を作るには?

高品質なニンニク粉の主な基準は、自然な色、純粋な香り、均一な細かさ、低水分、衛生的な安全性です。料理の風味を高めるだけでなく、食品業界で一貫した味を提供します。

最新の生産ラインで作られたニンニク粉は、乾燥温度と粉砕の細かさを正確に制御でき、純度と一貫性を確保します。本当に高品質なニンニク粉です。

品質指標の参考

| テスト項目 | 高品質ニンニク粉の基準 |

|---|---|

| 外観 | 淡黄色またはオフホワイトで、塊はありません |

| 香り | 純粋なニンニクの香りで、異臭はありません |

| 水分含有量 | ≤5% |

| 不純物 | 汚れ、異物、金属粒子はありません |

| 細かさ(メッシュ) | 40〜100メッシュ(カスタマイズ可能) |

| 微生物限界 | HACCP、ISO、FDA基準を満たす |

ニンニク粉の用途と市場展望

現代のニンニク粉は単なる調味料ではなく、食品業界や国際貿易においても重要な原料です。広く使用されています:

- 調味料製造: ニンニク塩、バーベキューパウダー、複合スパイスなど。

- 即食食品: ピザ、ハンバーガー、フライドチキン、インスタントラーメン。

- 健康食品: アリシンカプセル、ニンニク粉末錠剤。

- 飼料と農業: 天然の抗菌添加剤として、抗生物質の代わりに。

ヨーロッパ、北米、東南アジア、中東でニンニク粉の需要が増加しており、農産加工において利益の出る製品となっています。

シュリイと提携

ニンニク粉の製造は単なる粉砕以上のものであり、科学的で正確、かつ自動化された工程です。クローブの分離から包装まで、各工程が製品の品質と市場競争力に影響します。

シュリイの ニンニク粉生産ライン は、高効率、食品グレードの安全性、知能制御で知られています。顧客がニンニクの価値を最大化できるよう支援し、各クローブが最高の経済効果を得られるようにします。このプロジェクトに興味がある方は、右側のポップアップからお気軽にお問い合わせください。