Onion Ring Cutting Machine

The onion ring cutting machine, also called the onion slicer, is a machine that quickly cuts peeled onions into even rings or slices. It is widely used in food processing factories, central kitchens, ready-to-cook vegetable workshops, frozen food factories, and onion processing plants.

This electric onion ring cutting machine can cut both large and small onions. It is also suitable for cutting other round ingredients, such as potatoes, carrots, cucumbers, and bananas. For onions of different sizes, we can customize different feed openings.

The onion ring cutter can adjust the thickness of onion rings between 1mm and 5mm. Made of 304 stainless steel, it allows continuous feeding and cutting. The cut pieces are uniform, and it is more efficient and consistent than manual cutting.

The Working Principle of the Onion Ring Cutting Machine

The onion ring cutting machine feeds peeled onions into the cutting area through a cylindrical feeding device. High-speed rotating stainless steel blades cut the onions to a set thickness, instantly forming uniform onion rings between 2mm and 5mm. The cut onion rings are automatically discharged from the outlet.

Main Structure

The onion ring cutter mainly consists of a frame, motor, feed inlet, discharge outlet, and high-strength cutting rotary blades.

Feed Inlet: Usually made of four cylinders of different diameters, it can accommodate various sizes of raw materials.

Rotary Blades: Made of high-strength stainless steel, these are the core components of the onion ring cutting machine. The blades are sharp and wear-resistant, with adjustable cutting spacing to ensure uniform onion ring thickness, neat slices, and low breakage rate.

Technical Specifications of the Onion Ring Cutting Machine

| Parameter | Specification |

|---|---|

| Model | SL-30 |

| Capacity | 300–500 kg/h |

| Dimension | 720 × 620 × 1020 mm |

| Feed Hole Sizes | 55 / 70 / 90 / 100 mm |

| Voltage | 220V / 50Hz |

| Power | 0.75 kW |

| Slice Thickness | ≥ 1 mm |

Notes: The power voltage and material are customizable.

SL-30 Onion Ring Maker Features and Advantages

High Capacity

Can cut 300–500 kg of onions per hour, improving efficiency and saving labor.

Multiple Feed Sizes

Equipped with four hole diameters (55 / 70 / 90 / 100 mm) to handle onions of different sizes.

Precise Slicing

Slice thickness is adjustable from ≥1 mm, producing uniform and neat onion rings.

Precise Slicing

Slice thickness is adjustable from ≥1 mm, producing uniform and neat onion rings.

Precise Slicing

Slice thickness is adjustable from ≥1 mm, producing uniform and neat onion rings.

Precise Slicing

Slice thickness is adjustable from ≥1 mm, producing uniform and neat onion rings.

Precise Slicing

Slice thickness is adjustable from ≥1 mm, producing uniform and neat onion rings.

Durable Structure

Integrated feeding system, high-speed blade set, and discharge system ensure stable and continuous production.

Applications

The onion ring cutting machine is suitable for the following industries and products:

- Onion ring frying production lines

- Fast-food chain central kitchens

- Frozen prepared food factories

- Fresh-cut vegetable processing and distribution centers

- Vegetable deep-processing enterprises

It can process various types of onions, including white, red, and purple onions, as well as onions of different sizes, into uniform rings.

Value of Using the Onion Ring Cutting Machine

- Increase Production Efficiency: Automated cutting handles 300–500 kg of onions per hour, greatly reducing manual cutting time.

- Reduce Labor Costs: Automatic feeding, cutting, and discharge minimize manual operations and labor input.

- Ensure Product Quality: Uniform slice thickness and complete, attractive onion rings ensure standardized production and low breakage rates.

- Energy Saving and Environmentally Friendly: Low power design (0.75 kW) consumes less electricity and reduces operating costs.

- Adapt to Various Onion Sizes: Multi-hole design suits onions of different sizes without frequent equipment changes.

- Food Safety Assurance: Made of food-grade stainless steel, corrosion- and rust-resistant, easy to clean, meeting hygiene standards.

- Reduce Production Risks: Stable and durable structure minimizes downtime and operational errors.

- Enhance Competitiveness: Efficient, standardized production improves processing capacity and brand image, facilitating business expansion and upgrades.

How to Choose an Onion Ring Cutter?

- Capacity Matching: Select a machine that meets your daily processing volume, with an hourly capacity suitable for your needs (e.g., 300–500 kg/h).

- Flexible Cutting Specifications: Adjustable slice thickness to handle onions of different sizes, ensuring uniform and attractive products.

- Material and Hygiene Safety: Key parts made of 304 stainless steel, corrosion- and rust-resistant, easy to clean, and compliant with food safety standards.

- Energy Efficiency and Power Compatibility: Moderate power and matching workshop voltage ensure stable operation and lower electricity costs.

- Stability and Durability: Solid structure and wear-resistant blades support continuous production, reducing downtime and maintenance costs.

- Easy Operation and Maintenance: Automatic feeding, cutting, and discharge; simple to operate and easy to disassemble and clean, saving labor.

- Versatile Application: Can cut onions of different sizes or other vegetables, increasing equipment utilization.

- After-Sales and Certification: Choose machines with a warranty, after-sales service, and food safety certification to ensure long-term stable production.

Packaging delivery

- Machines are wrapped in plastic film first before packing, to avoid moisture on the sea.

- The machines are put in a wooden case, which is free of fumigation, lined with metal wire if necessary.

Services Provided by Shuliy

- Professional Selection: Recommend suitable equipment based on capacity, raw materials, and requirements.

- Customized Solutions: Design capacity, configuration, or complete production lines according to customer needs.

- Manufacturing and Quality Assurance: Produced in our own factory, meeting CE/ISO/SGS/BV/TUV standards.

- Installation, Commissioning, and Training: Engineers provide on-site installation, commissioning, and operator training.

- After-Sales Service and Warranty: 12-month warranty and spare parts support.

- Technical Support and Long-Term Maintenance: Guidance for equipment maintenance and supply of wear parts.

- Export and Logistics Support: Experienced in international shipping and packaging, supporting overseas customers.

In addition to the onion root cutting machine, Shuliy also offers a full range of onion processing equipment, including onion peeling machines and more.

Hot Product

Garlic Slicer Machine

Garlic slicer high performance, multi-functional, easy control of…

Garlic Powder Grinding Machine

The garlic powder grinding machine applies for grinding…

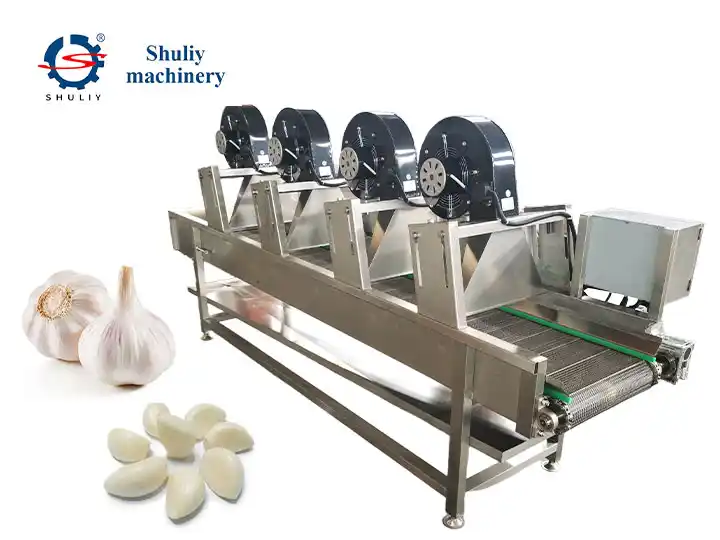

Garlic Air Drying Machine

The garlic air drying machine is a highly…

Garlic Cleaning Machine

A fully automatic high-yield multifunctional garlic washing machine,…

Garlic Clove Vacuum Packing Machine

Garlic clove vacuum packing machine with 20L copper-core…

Garlic peeling production line | Garlic processing machine

The garlic peeling production line is very practical…

Manual Garlic Harvesting Machine

Garlic harvesting machine helps farmers to harvest garlic…

Double belts garlic root concave cutting machine

The garlic concave root cutting machine removes the…

Ginger Garlic Paste Making Machine

Automatic ginger garlic paste making machine is widely…