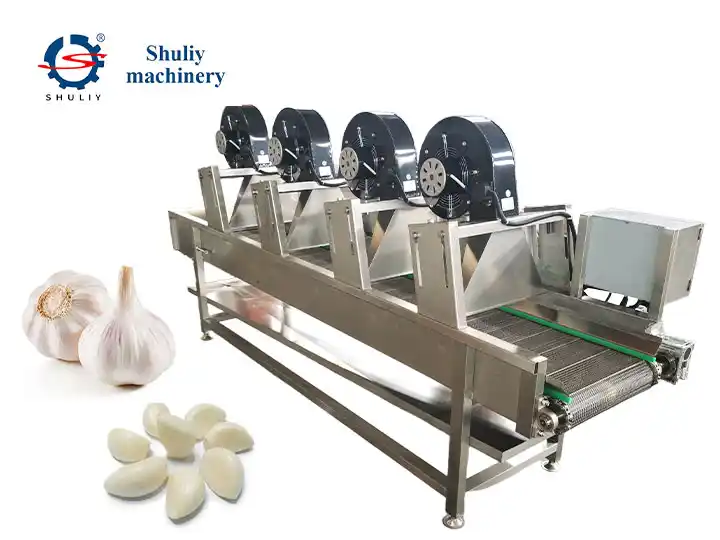

Máquina de Secagem de Alho ao Ar Livre

A máquina de secagem a ar de alho é uma solução altamente eficiente e econômica para a remoção de umidade superficial dos dentes de alho. A máquina seca rapidamente a superfície sem danificar a casca externa, garantindo que os dentes permaneçam intactos e prontos para processamento ou embalagem posterior.

Velocidade de Embalagem: 24-60 sacos/min

Capacidade: 500-1500kg/h

Como funciona a máquina de secagem de alho?

Processo de secagem de alho:

Alimentação do alho → Secagem com faca de ar → Viragem durante a secagem → Remoção de umidade → Descarga

A máquina de secagem a ar de alho funciona usando sopradores de ar de alta pressão e facas de ar para remover a umidade superficial dos dentes de alho após a lavagem. Aqui está como o processo funciona.

- Alimentação do alho: Os dentes de alho limpos são alimentados uniformemente na esteira do equipamento.

- Secagem com faca de ar: À medida que o alho avança, ele passa por uma série de lâminas de ar de alta velocidade, que sopram ar forte e concentrado nas cabeças de alho de vários ângulos.

- Viragem durante a secagem: O transportador pode ser equipado com um mecanismo de rotação para girar suavemente o alho, de modo que todos os lados sejam secos uniformemente.

- Remoção de umidade: A corrente de ar forte é eficaz na remoção de gotas de água da superfície e não danifica a pele do alho.

- Descarga: Em seguida, os dentes de alho secos são liberados no final da esteira e estão preparados para processamento adicional, por exemplo, descascamento, fatiamento ou embalagem.

Por que escolher o desidratador de alho a ar mais vendido da Shuliy?

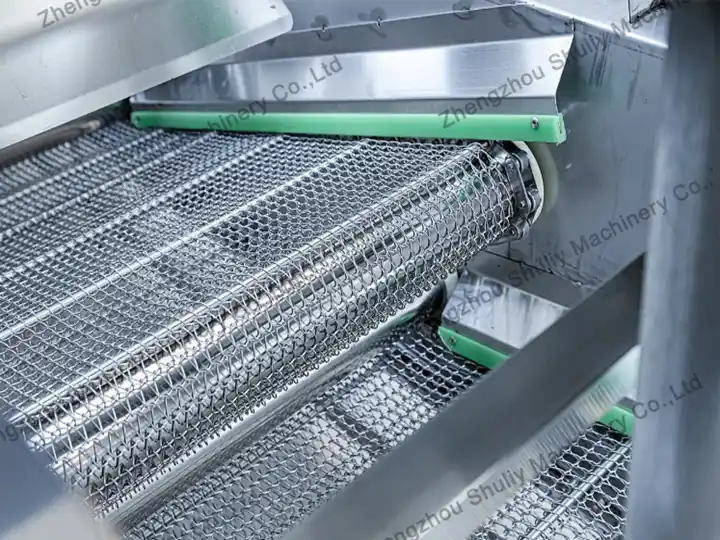

Corrediça de Alimentação: A máquina utiliza uma correia de malha em aço inoxidável SUS304 de alta qualidade, oferecendo excelente resistência à corrosão e ferrugem. Existe uma opção atualizada com malha de corrente maior e mais espessa, proporcionando uma vida útil significativamente mais longa do que as correias de malha tradicionais. Garante um funcionamento suave e estável, sem encravamentos ou quebras. O comprimento da correia de malha e o tamanho dos furos podem ser personalizados de acordo com as necessidades de processamento. Adequado para linhas de produção contínua.

Sopladores de Alta Pressão: A máquina está equipada com um soprador multimblade de alto volume especialmente personalizado pela nossa empresa. Apresenta baixo consumo de energia, fluxo de ar forte, baixo ruído e alta pressão de vento, assegurando uma secagem uniforme a 360 graus sem cantos mortos. O uso de bobinas de cobre puro garante um desempenho estável, duradouro e contínuo.

Painel de Controlo: Equipado com um inversor de frequência variável (VFD) para ajuste de velocidade, permitindo controlo preciso da velocidade de funcionamento da máquina e possibilitando que os clientes gerenciem facilmente o ritmo de produção.

Estrutura e Carcaça da Máquina: A máquina inteira é feita de aço inoxidável 304 de grau alimentar, durável, resistente à corrosão e totalmente compatível com padrões de higiene no processamento de alimentos.

Pós-venda: Uma equipe profissional de pós-venda fornece uma resposta rápida 24 horas. Serviço gratuito dentro de um ano e manutenção vitalícia (apenas cobrando o custo de peças). Instalação e comissionamento concluídos com operação prática no local e formação gratuita em manutenção. Engenheiros estão sempre disponíveis para fornecer vários serviços técnicos.

Quais modelos estão disponíveis para a máquina de secagem a ar de alho?

| Modelo | Tamanho (mm) | Peso (Kg) | Poder | Capacidade |

| SL-3000 | 3000*1200*1600mm | 400 | 7.5kw | 500kg/hora |

| SL-4000 | 4000*1200*1600mm | 600 | 10.1kw | 800kg/hora |

| SL-5000 | 5000*1200*1600mm | 800 | 13.6kw | 1000kg/hora |

| SL-6000 | 6000*1200*1600mm | 1300 | 13.6kw | 1500kg/h |

Os acima são apenas nossos modelos padrão. Podemos projetar e personalizar de acordo com suas necessidades. Você é bem-vindo para nos contatar para consultas.

Faixa de Preenchimento: até 80g

- Plantas de processamento primário de alho Consumo de Energia: 2.2kw

- Fábricas de processamento de produtos agrícolas — adequado para secagem ao ar de vários produtos, como cebolas, gengibre, pimentas e mais.

- Fábricas de processamento de alimentos — para pré-secagem de vários vegetais e frutas para prolongar a vida útil.

- Processamento de medicina tradicional chinesa — secagem ao ar de ervas medicinais para melhorar a eficiência de secagem.

- Esta máquina de classificação de frutas do tipo tambor adota a classificação de boca de sino, o que torna o espaçamento dos buracos de classificação mais padronizado. — pré-tratamento de frutas e vegetais para reduzir o risco de apodrecimento e mofo.

- Linhas de produção contínuas Nota sobre a máquina de descascar alho em uso e armazenamento 3

Como manter a máquina de secagem de alho

Limpeza regular

- A máquina quebradora de bulbos de alho pode dividir alho de tamanhos diferentes? 12

- A máquina quebradora de bulbos de alho pode dividir alhos de tamanhos diferentes? 13

A máquina quebradora de bulbos de alho pode dividir alhos de tamanhos diferentes? 14

- Como descascar um dente de alho rapidamente? 15

- Como descascar um dente de alho rapidamente? 16

Como descascar um dente de alho rapidamente? 17

- Como separar os dentes de alho para plantar? 18

Como separar os dentes de alho para plantar? 19

- Como é que a planta de alho descasca a pele do alho rapidamente? 20

- Como é que a planta de alho descasca a pele do alho rapidamente? 21

Como a planta de alho descasca a pele do alho rapidamente? 22

- Como escolher uma planta de desidratação de cebola e alho adequada? 23

Como escolher uma planta de desidratação de cebola e alho adequada? 24

- Como escolher uma planta de desidratação de cebola e alho adequada? 25

Máquina comercial de descasque de cebola e alho a preço de fábrica 26

- Máquina comercial de descasque de cebola e alho a preço de fábrica 27

Máquina comercial de descasque de cebola e alho a preço de fábrica 28

Produto quente

Linha de produção de alho em pó

A linha de produção de pó de alho inclui principalmente alho…

Máquina de descascar alho

Uma máquina de descascamento de alho é projetada para descascar…

Máquina de Embalagem de Pó de Alho | Máquina Automática de Embalagem de Pó de Alho

Esta máquina de embalar o powder de alho é totalmente…

Máquina de Plantar Alho

A máquina de plantio de alho é uma ferramenta agrícola…

Máquina de Fatiar Alho

Esta máquina fatiadora de alho é fácil de operar…

Máquina de Corte de Talos de Raiz de Alho

A máquina de corte de caules de alho aplica-se para cortar…

Linha de produção de descascamento de alho | Máquina de processamento de alho

A linha de produção de descascamento de alho é muito prática…

Máquina de Desidratação de Alho | Forno Industrial de Secagem de Alho

A máquina de desidratação de alho é uma circulação de ar quente…

Moinho de Pó de Alho

A máquina de moagem de pó de alho aplica-se à moagem…