Máquina de secado de ajo | Secadora de correa de ajo

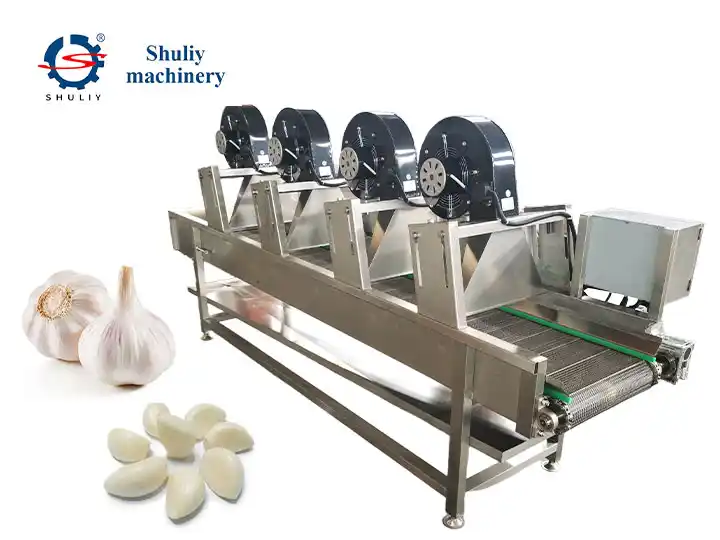

The garlic drying machine, commonly known as a continuous food dehydrator or continuous belt dryer, can be used for dehydrating garlic slices. The dried garlic slices obtained can be ground into garlic powder for secondary processing.

This drying machine features fast drying speed and uniform drying performance, and it is widely used in the food, pharmaceutical, chemical, construction, and electronics industries.

Kikausha vitunguu cha moja kwa moja kabisa kinafaa hasa kwa kukausha malighafi zilizokatwa kwa umbo la vipande, mikodi, na chembe ambazo zina unyevu mkubwa na huzizwa na joto kali, kama vipande vya vitunguu na vipande vya tangawizi.

Shuliy offers seven types of garlic drying machines, with drying lengths ranging from 8 to 20 meters to meet different production requirements. It can handle material thicknesses of 10–80 mm, ensuring uniform heating of garlic slices. The average drying time ranges from 0.2 to 3 hours, providing fast and efficient drying. Compared to conventional belt dryers, Shuliy’s machines save nearly 50% of the processing time.

Upeo wa matumizi ya mashine ya kukausha vitunguu

The automatic garlic dehydrator adopts a steel mesh conveyor design and can be widely used for drying and sterilizing various foods, including snacks, agricultural products, fish fillets, meat slices, bean products, instant noodles, fast food, tea, Chinese medicinal materials, fruits and vegetables, and seasoning powders. It is suitable for granular, sliced, and strip-shaped materials.

This machine is applied in fields such as food processing, agricultural product storage, seasoning production, healthcare, and international trade.

Mashine ya kukausha vitunguu vipengele vya muundo

- 380v,50hz: 1.2–2.2 m, urefu wa kukausha: 8–20 m, inafaa kwa uwezo tofauti wa uzalishaji.

- Unene wa vifaa: 10–80 mm, ina uwezo wa kukausha aina mbalimbali za vifaa.

- Joto la kukausha: 50–140°C, shinikizo la mvuke: 0.2–0.8 MPa.

- Uwezo wa kukausha: 60–600 kg/h, na wakati mfupi wa kukausha wa hadi saa 0.2, kuhakikisha operesheni ya haraka na ufanisi.

- Matumizi ya mvuke: 120–1200 kg/h, na ufanisi wa joto wa juu.

- Jumla ya nguvu: 11.4–36.8 kW, kuhakikisha operesheni ya kiwango cha juu cha mara kwa mara.

- Ujenzi thabiti: uzito wa mashine 4500–14000 kg, inafaa kwa matumizi ya muda mrefu ya uzito mkubwa.

- Made of high-strength steel, wear-resistant, pressure-resistant, and corrosion-resistant.

- Maombi makubwa: Inafaa kwa kukausha mbao, nafaka, pellets, biomass, na vifaa vingine, kwa udhibiti sahihi wa joto na nguvu ya kukausha.

Muundo wa mashine ya kukausha vitunguu

- Mfumo wa kupakia: Vifaa vinatolewa sawasawa kwenye mkanda wa conveyor baada ya kupakiwa. Unene wa safu unaweza kubadilishwa: 10–80 mm.

- Mfumo wa mkanda wa conveyor: Upana wa mkanda: 1.2–2.2 m, kasi inayoweza kubadilishwa, kwa kawaida safu 3–5. Imetengenezwa na chuma cha pua cha kiwango cha chakula kwa ajili ya kuendelea kupakia kwenye eneo la kukausha.

- Chumba cha kukausha: Urefu wa kukausha: 8–20 m, joto la kazi: 50–140°C, shinikizo la mvuke: 0.2–0.8 MPa. Vifaa vinapashwa joto na hewa moto au mvuke kwa ajili ya evaporation ya unyevunyevu.

- Mfumo wa kupasha joto: Inatoa nishati ya joto. Chaguzi: mvuke, tanuru ya hewa moto, kupasha joto kwa umeme, au kupasha joto kwa gesi.

- Mfumo wa mzunguko wa hewa na uingizaji hewa: Mzunguko wa hewa moto na uingizaji hewa wa unyevunyevu, kuweka joto la chumba thabiti. Kiasi cha hewa kinachoweza kubadilishwa, kiwango cha uingizaji hewa kinategemea unyevunyevu wa vifaa.

- Mfumo wa usafirishaji na udhibiti: Jumla ya nguvu: 11.4–36.8 kW. Mchakato wa kusukuma unaendeshwa na motor, na PLC udhibiti wa joto, kasi, na unyevunyevu.

Technical Specification

| Mfano | SL-1.2-8 | SL-1.2-10 | SL-1.6-8 | SL-1.6-10 | SL-2-8 | SL-2-10 | SL-2-20 |

| Vifaa | 4 | 5 | 4 | 5 | 4 | 5 | 10 |

| Upana wa mkanda (m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

| Urefu wa kukausha (m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 |

| Unene wa malighafi (mm) | 10-80 | ||||||

| Joto la huduma (°C) | 50-140 | ||||||

| Shinikizo la mvuke (MPa) | 0.2-0.8 | ||||||

| Matumizi ya mvuke (kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 |

| Muda wa kukausha (h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 |

| Uwezo wa kukausha (kg/h) | 60-160 | 820-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 |

| Jumla ya nguvu | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 |

| Urefu (m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Upana (m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Urefu wa juu (m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 |

| Uzito wote (kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 |

The above chart presents 7 of our garlic dehydrator machine models. The belt width and length can be customized according to the customers’ needs.

Je, ni faida gani kuu za kikaushio cha kukata vitunguu kiotomatiki?

- Mashine ya kuondoa majimaji ya vitunguu saumu inaweza kuwa aina ya mkanda wa matundu yenye safu nyingi, yenye udhibiti wa joto kiotomatiki, uenezaji wa nyenzo kiotomatiki, na uzalishaji unaoendelea.

- All parts in contact with the product are made of food-grade stainless steel, ensuring hygienic drying.

- The garlic slice belt dryer is a newly developed type of equipment on the basis of the traditional belt dryer, with high energy utilization efficiency.

- Mbalimbali ya maombi. Kikaushio cha kipande cha vitunguu kinafaa kwa upungufu wa maji mwilini na kukausha kwa mboga na matunda mbalimbali za kikanda na za msimu. Kama vile vipande vya vitunguu swaumu, malenge, konjaki, figili nyeupe, viazi vikuu, machipukizi ya mianzi, n.k.

- Huduma zinazopatikana za ubinafsishaji ili kukidhi mahitaji tofauti ya usindikaji kulingana na uwekezaji tofauti.

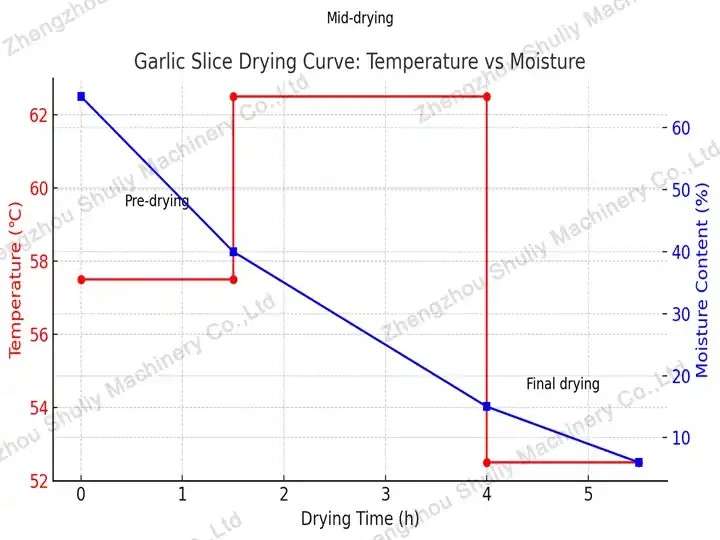

How does a garlic drying machine dry garlic slices?

Below, we will take our machine as an example to demonstrate the garlic slice drying process.

Breaks whole garlic bulbs into individual cloves.

Peels garlic cloves with a peeling rate of over 95%, without damaging the garlic.

Removes spoiled cloves and washes garlic in bulk using bubble cleaning.

Mashine ya kukata vitunguu saumu

Slice the garlic into pieces with a thickness of 2–3 mm.

Garlic drying machine

Dry the garlic slices for further processing or storage.

Udhibiti wa Joto (Kumbukumbu)

- Mwanzo: 55–60°C → Kuondoa haraka unyevu wa uso

- Katikati: 60–65°C → Kukauka kwa utulivu

- Mwisho: 50–55°C → Uondoaji wa unyevu kwa joto la chini ili kuzuia kubadilika rangi

Temperature control is related to the thickness of your material layer. The above is only a reference. The exact temperature and humidity should be adjusted according to your specific situation. If you are not sure how to set it up, we can provide support and help you complete the production

Aina nyingine ya mashine ya kuondoa maji ya vitunguu

Ifuatayo ni aina nyingine ya jiko la kukaushia kitunguu saumu cha viwandani, lenye idadi ya trela na trei kwa ajili ya kukausha kwa mafungu.

If you want to know more about the garlic drying room, you can also contact us for more information.

Bidhaa Moto

Mashine ya Kukata Viazi vya Kitunguu saumu | Kichakataji cha Kitaaluma cha Kitunguu saumu

Mashine ya kung’unya vitunguu saumu ya aina ya mnyororo imetengenezwa mahsusi…

, na sehemu nyingine kuu. Mashine inajumuisha

Mashine hii ya kufunga unga wa vitunguu ni kiotomatiki kikamilifu…

Máquina de secado de ajo | Secadora de correa de ajo

Mashine ya kuondoa unyevu wa vitunguu inajulikana kawaida kama…

Maskin för plantering av vitlök

Mashine ya kupanda vitunguu saumu ni chombo cha kilimo…

Máquina de separación de dientes de ajo

Mashine ya kutenganisha vipande vya kitunguu imeundwa kutenganisha kwa ufanisi…

Kinu cha Mzunguko wa Kitunguu

Mashine ya kukata ring ya kitunguu saumu, pia inaitwa…

Máquina de molienda de polvo de ajo

Mashine ya kusaga unga wa vitunguu inafaa kwa kusaga…

Vitlökslufttorkmaskin

Mashine ya kukausha vitunguu kwa hewa ni sana…

Mashine ya Kumenya Vitunguu

Mashine ya kupolia vitunguu imeundwa kuondoa…