Sarımsak Kurutma Makinesi | Sarımsak Bant Kurutucusu

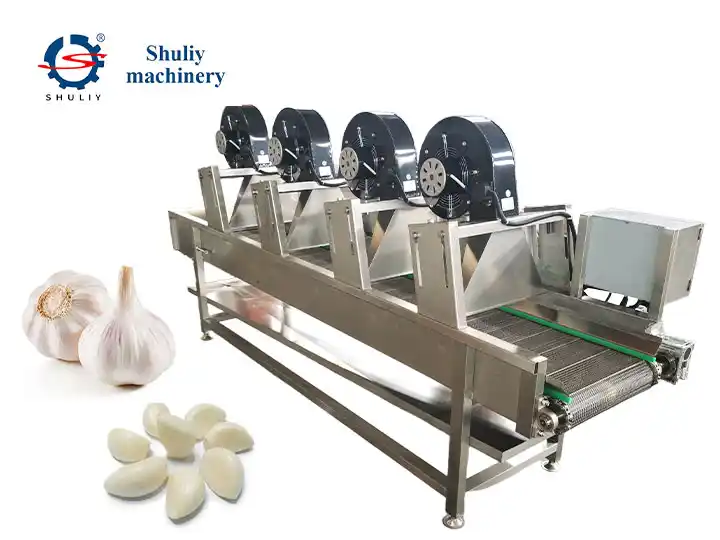

The garlic drying machine, commonly known as a continuous food dehydrator or continuous belt dryer, can be used for dehydrating garlic slices. The dried garlic slices obtained can be ground into garlic powder for secondary processing.

This drying machine features fast drying speed and uniform drying performance, and it is widely used in the food, pharmaceutical, chemical, construction, and electronics industries.

Tam otomatik sarımsak kurutucu özellikle sarımsak dilimleri ve zencefil dilimleri gibi yüksek nem içeriğine sahip ve yüksek sıcaklıklara hassas olan dilim-, şerit- ve granül şeklindeki malzemelerin kurutulması için uygundur.

Shuliy offers seven types of garlic drying machines, with drying lengths ranging from 8 to 20 meters to meet different production requirements. It can handle material thicknesses of 10–80 mm, ensuring uniform heating of garlic slices. The average drying time ranges from 0.2 to 3 hours, providing fast and efficient drying. Compared to conventional belt dryers, Shuliy’s machines save nearly 50% of the processing time.

Sarımsak kurutma makinesinin uygulama kapsamı

The automatic garlic dehydrator adopts a steel mesh conveyor design and can be widely used for drying and sterilizing various foods, including snacks, agricultural products, fish fillets, meat slices, bean products, instant noodles, fast food, tea, Chinese medicinal materials, fruits and vegetables, and seasoning powders. It is suitable for granular, sliced, and strip-shaped materials.

This machine is applied in fields such as food processing, agricultural product storage, seasoning production, healthcare, and international trade.

Sarımsak kurutma makinesi Yapısal özellikler

- Kayış genişliği: 1.2–2.2 m, kurutma uzunluğu: 8–20 m, farklı üretim kapasitelerine uygun.

- Malzeme kalınlığı: 10–80 mm, geniş malzeme yelpazesinin kurutulmasına olanak tanır.

- Kurutma sıcaklığı: 50–140°C, buhar basıncı: 0.2–0.8 MPa.

- Kurutma kapasitesi: 60–600 kg/s, kısa kurutma süresiyle sadece 0.2 saat, hızlı ve verimli çalışma sağlar.

- Buhar tüketimi: 120–1200 kg/s, yüksek termal verimlilik ile.

- Toplam güç: 11.4–36.8 kW, sürekli yüksek yoğunlukta çalışma sağlar.

- Sağlam yapı: Makine ağırlığı 4500–14000 kg, uzun vadeli ağır hizmet kullanımı için uygun.

- Made of high-strength steel, wear-resistant, pressure-resistant, and corrosion-resistant.

- Geniş uygulama alanları: Ahşap, tahıl, pelet, biyokütle ve diğer malzemelerin kurutulması için uygundur, sıcaklık ve kurutma şiddetinin hassas kontrolü ile.

Yapısı of sarımsak kurutma makinesi

- Besleme sistemi: Malzemeler, beslemeden sonra konveyör bandına eşit şekilde dağıtılır. Katman kalınlığı ayarlanabilir: 10–80 mm.

- Konveyör bandı sistemi: Bant genişliği: 1.2–2.2 m, ayarlanabilir hız, genellikle 3–5 katman. Sürekli besleme için gıda sınıfı paslanmaz çelik örgü kullanılır.

- Kurutma odası: Kurutma uzunluğu: 8–20 m, çalışma sıcaklığı: 50–140°C, buhar basıncı: 0.2–0.8 MPa. Malzemeler, nem buharlaştırmak için sıcak hava veya buhar ile ısıtılır.

- Isıtma sistemi: Isı enerjisi sağlar. Seçenekler: buhar, sıcak hava fırını, elektrikli ısıtma veya gaz ısıtma.

- Hava dolaşımı ve egzoz sistemi: Nem tahliyesi ile sıcak hava dolaşımı, odanın sıcaklığını stabil tutar. Hava hacmi ayarlanabilir, egzoz oranı malzemenin nemine bağlıdır.

- Tahrik ve kontrol sistemi: Toplam güç: 11.4–36.8 kW. Konveyör motor tarafından tahrik edilir, sıcaklık, hız ve nem otomatik PLC kontrolü ile sağlanır.

Technical Specification

| Modeli | SL-1.2-8 | SL-1.2-10 | SL-1.6-8 | SL-1.6-10 | SL-2-8 | SL-2-10 | SL-2-20 |

| Birimler | 4 | 5 | 4 | 5 | 4 | 5 | 10 |

| Bant genişliği(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

| Kurutma uzunluğu(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 |

| Malzeme kalınlığı(mm) | 10-80 | ||||||

| Hizmet sıcaklığı(°C) | 50-140 | ||||||

| Buhar basıncı(Mpa) | 0.2-0.8 | ||||||

| Buhar tüketimi(kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 |

| Kurutma süresi(saat) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 |

| Kurutma yoğunluğu(kg/h) | 60-160 | 820-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 |

| Toplam güç | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 |

| Uzunluk(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Genişlik(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Yükseklik(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 |

| Toplam ağırlık(kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 |

The above chart presents 7 of our garlic dehydrator machine models. The belt width and length can be customized according to the customers’ needs.

Otomatik sarımsak dilimleme kurutucusunun olağanüstü avantajları nelerdir?

- Sarımsak kurutucu makinesi, otomatik sıcaklık kontrolü, otomatik malzeme yayma ve sürekli üretim ile çok katmanlı örgü bant tipi olabilir.

- All parts in contact with the product are made of food-grade stainless steel, ensuring hygienic drying.

- The garlic slice belt dryer is a newly developed type of equipment on the basis of the traditional belt dryer, with high energy utilization efficiency.

- Geniş uygulama yelpazesi. Sarımsak dilimleme makinesi, çeşitli bölgesel ve mevsimlik sebze ve meyvelerin kurutulması ve kurutulması için uygundur. Sarımsak dilimleri, balkabağı, konjac, beyaz turp, tatlı patates, bambu filizleri vb.

- Farklı yatırımlara göre farklı işleme ihtiyaçlarını karşılamak için mevcut özelleştirme hizmetleri.

How does a garlic drying machine dry garlic slices?

Below, we will take our machine as an example to demonstrate the garlic slice drying process.

Breaks whole garlic bulbs into individual cloves.

Peels garlic cloves with a peeling rate of over 95%, without damaging the garlic.

Removes spoiled cloves and washes garlic in bulk using bubble cleaning.

Slice the garlic into pieces with a thickness of 2–3 mm.

Garlic drying machine

Dry the garlic slices for further processing or storage.

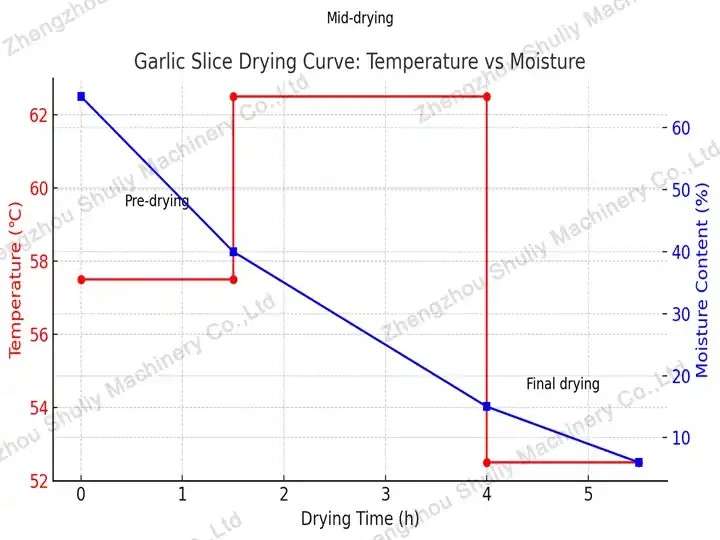

Sıcaklık Kontrolü (Referans)

- İlk: 55–60°C → Yüzey nemini hızlıca uzaklaştırın

- Orta: 60–65°C → Kararlı kurutma

- Son: 50–55°C → Sararmayı önlemek için düşük sıcaklıkta nem uzaklaştırma

Temperature control is related to the thickness of your material layer. The above is only a reference. The exact temperature and humidity should be adjusted according to your specific situation. If you are not sure how to set it up, we can provide support and help you complete the production

Başka bir tür sarımsak dehidrasyon makinesi

Aşağıdakiler, bir sürü rafa sahip ve parti kurutma için çok sayıda arabalar ve tepsiler içeren endüstriyel sarımsak kurutma fırını türüdür.

If you want to know more about the garlic drying room, you can also contact us for more information.

Sıcak Ürün

son düzenleme: 2025/6/18

Bu sarımsak tozu paketleme makinesi tamamen…

Çift kemerli sarımsak kökü içbükey kesme makinası

Sarımsak içbükey kök kesme makinesi,…

Yarı Otomatik Sarımsak Tozu Paketleme Makinesi

Yarı otomatik sarımsak tozu paketleme makinesi kullanılır…

Sarımsak Zincir Tipi Soyma Makinesi | Ticari Sarımsak Soyucu

Zincir tipi sarımsak soyma makinesi özel olarak tasarlanmıştır…

Soğan Halkası Kesme Makinesi

Soğan halkası kesme makinesi, ayrıca ...

Sarımsak Hava Kurutma Makinesi

Sarımsak hava kurutma makinesi son derece…

Sarımsak Ekimi Makinesi

Sarımsak ekim makinesi bir tarım aracıdır…

Sarımsak Sınıflandırma Makinesi

Ticari sarımsak sınıflandırma makinesi, sınıflandırmak için silindirleri kullanır…

Sarımsak Toz Öğütme Makinesi

Sarımsak tozu öğütme makinesi öğütme için geçerlidir…