半自动大蒜粉包装机是一种用于将大蒜粉准确填充到包装容器中的设备。它也适用于食品、化工、农业和其他行业的粉状材料包装。

该机器采用螺旋计量方式,确保计量准确,操作简便。可包装成袋装、瓶装、罐装等多种形式。

本机操作简单,精度高,适应性强。其包装精度控制在±1%,包装速度为500–1500 袋/小时。包装重量可在1至10 千克之间调整。

该机器还可以与喂料机和封口机配合使用,在大蒜粉生产线上发挥关键作用。

半自动大蒜粉包装机的优点

- 自动计量系统: 集成机械、电气、光学和仪器技术,由微控制器控制,自动完成称重、填充和误差修正。

- 快速包装速度:采用螺旋喂料系统和光电控制,实现快速响应和高效率。

- 高测量精度: 配备高性能电子秤和步进电机,实现精确控制。

- 卫生和安全: 完全由食品级不锈钢(SUS304)制成,易于清洁,有效防止交叉污染。

- 广泛的包装范围:通过键盘可调节,范围从1到10公斤,改变螺丝可适应不同尺寸。

- 广泛的材料兼容性: 除了大蒜粉外,适用于各种自由流动的粉状材料。

- 智能错误修正: 自动跟踪并纠正由于材料密度变化或材料水平波动引起的错误。

- 操作简单: 只需手动放置袋子;光电传感器控制自动喂料,保持袋口整齐,随时准备封口。

手动大蒜粉包装机的组成和工作原理

储存斗

储存大蒜粉以确保连续供料。采用不锈钢制造,易于清洁,防止粘连。

螺旋送料系统

根据设定的量将粉末从料斗推送到出口,电机控制以实现精确供料。

称重传感器与控制系统

使用电子秤实时监测每种饲料的重量,连接到PLC控制系统以实现自动称重和错误修正。

控制面板

允许设置包装尺寸、速度、误差范围等。配有显示屏和按钮,部分型号包括触摸屏界面。

排放口与填充喷嘴

称重后,粉末在此排放到手动放置的容器中。喷嘴可拆卸,易于更换以适应不同尺寸。

框架与外壳

机器框架由高质量不锈钢制成,坚固耐用,符合食品卫生标准。

合适的材料和应用场景

材料

| 行业类别 | 典型材料 |

| 食品行业 | 奶粉,淀粉,调味粉, 和酶制剂 |

| 农业产业 | 动物饲料,预混料,兽药, 农药粉 |

| 化学工业 | 添加剂,洗衣粉, 化学粉末 |

应用场景

- 食品加工厂

- 农产品生产线

- 饲料或添加剂包装站

- 化学产品包装车间

- 香料和调味品制造厂

- 电子商务包装操作

半自动大蒜粉包装机的技术参数

| 范围 | 规格 |

| 电源供应 | 交流380V,900W |

| 填充范围 | 1–10千克 |

| 包装精度 | ±1% |

| 包装速度 | 500–1500袋/小时 |

| 机器尺寸 | 1000 × 850 × 1850 毫米 |

| 机器重量 | 280 千克 |

我们还提供定制服务,可以根据您的要求修改机器。

如何使用半自动大蒜粉包装机?

- 连接电源: 确认电压为AC380V,并检查接地是否正确连接。

- 添加材料: 将粉状材料(如大蒜粉、奶粉等)倒入喂料机或料斗中。

- 检查: 确保料斗和螺杆干净,无杂物或残留粉末。

- 设置参数: 设置包装重量(例如,1kg、2kg等)/ 调整包装速度 / 设置允许误差范围(±1%)

操作流程:手动放置包装袋或瓶子 → 开始包装 → 自动称重与填充 → 填充完成后停止 → 取出已包装的袋子或瓶子。

可以一起使用哪些机器?

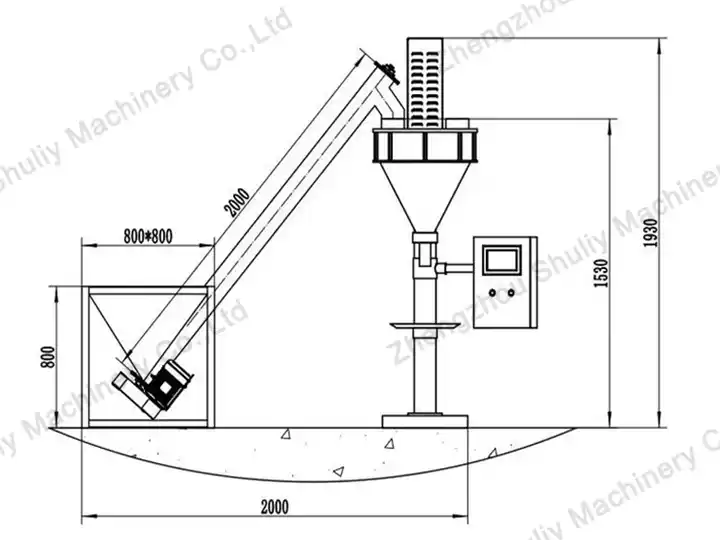

喂料机

| 范围 | 规格 |

| 提升能力 | 1000–3000 千克/小时 |

| 料斗容量 | 100–300公斤 |

| 喂料高度 | 2000毫米(可定制) |

| 电源供应 | AC 380V,1100W |

| 材料 | 不锈钢 |

| 机器重量 | 150公斤 |

连续封口机

| 范围 | 规格 |

| 电源供应 | 220V 50Hz 520W |

| 封口宽度 | 可调 5–14 毫米 |

| 封口材料厚度 | 0.03–0.80 毫米 |

| 封口能力 | 每分钟最多55袋(基于100毫米袋) |

| 封口速度 | 0–12米/分钟 |

| 温度范围 | 0–300°C |

| 机器尺寸 | 810 × 370 × 310 毫米 |

| 最大打印字符数 | ≤ 39 个字符 |

| 重量 | 17.5 千克 |

用于大蒜粉生产线的应用

在大蒜粉生产线中,包装机通常作为最后一步——包装工序使用。

对大蒜粉包装机进行维护和保养。

- 每天工作后清洁料斗和喂料管。

- 每周检查螺旋输送机是否磨损或堵塞。

- 每月检查电气控制系统和电线是否老化或松动。

- 润滑轴承部件(如适用)以延长机器使用寿命。

与我们合作

如有兴趣,请直接通过 WhatsApp 与我们联系:https://wa.me/+8619139761487

热门产品

大蒜清洗机

全自动高产多功能洗蒜机,…

双带蒜根凹切机

大蒜凹型根切割机去除了…

大蒜干燥机 | 大蒜带式干燥机

大蒜脱水机通常被称为…

大蒜根茎切割机

蒜根茎切割机适用于切割…

大蒜脱皮生产线|大蒜加工机

大蒜剥皮生产线非常实用…

大蒜链式去皮机 | 商用大蒜去皮器

链式大蒜剥皮机特别设计用于…

大蒜种植机

大蒜种植机是一种农业工具…

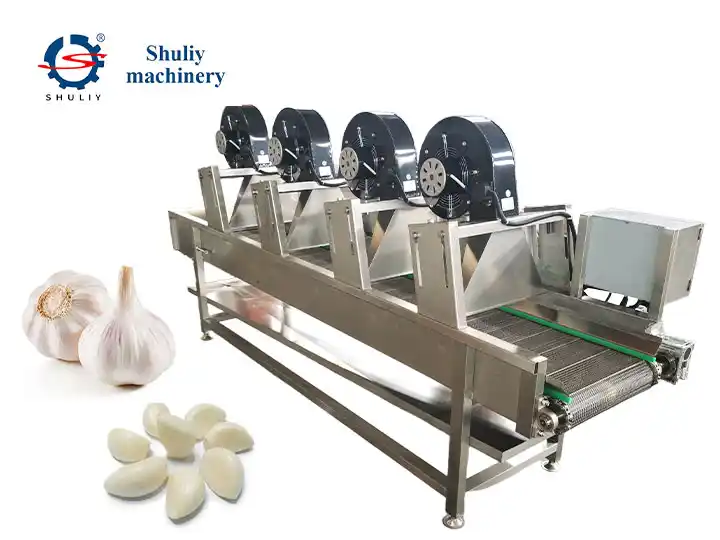

大蒜空气干燥机

大蒜风干机是一种高效的…

蒜瓣切片机

这款大蒜切片机操作简便…