Garlic Powder Packing Machine | Automatic Garlic Powder Packing Machine

Garlic powder is a common ingredient used in kitchens, the food industry, and even in medicine. As its use in food processing, seasonings, and instant foods grows, the demand for clean, efficient, and standardized packaging has increased. To meet this need, garlic powder packing machines have been developed and have become an ideal solution for powder packaging.

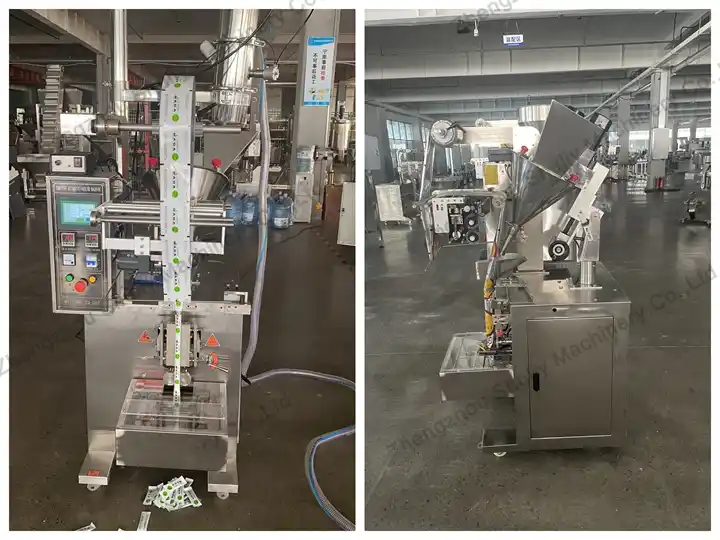

The garlic powder packing machine is a high-efficiency automatic machine specially designed for garlic powder. It usually uses a vertical structure (called VFFS) and combines bag making, weighing, filling, sealing, and cutting all in one. It’s perfect for packing garlic powder into bags. Besides garlic powder, it can also pack other fine powders like ginger powder, chili powder, and curry powder.

Shuliy’s garlic powder packaging machine is made entirely of SUS304 stainless steel, which is hygienic, dustproof, and anti-static. It has a fast packing speed of 24–60 bags/min and supports multiple functions such as filling, sealing, measuring, coding, and inkjet printing. Meanwhile, the machine production capacity can reach 1–50 ton/h.

This machine is widely used for bag packaging in industries like food processing, seasoning production, agriculture, and chemicals. It has been widely exported to more than 10 countries, including India, Saudi Arabia, Germany, Italy, Thailand, Vietnam, South Korea, and the United States.

What is the garlic powder packaging machine made of?

This garlic powder packaging machine mainly consists of an auger filling system, a vertical form-fill-seal (VFFS) machine, and a touch-screen PLC control system. The vertical packing unit includes automatic film pulling, bag forming, and vertical and horizontal heat sealing systems.

What are the functions of the garlic powder packaging machine?

The Shuliy packaging machine offers automatic weighing, bag forming, filling, sealing, cutting, fault detection with alarms, and coding/inkjet printing. It also supports customized add-ons such as nitrogen filling, dust removal, and automatic feeding systems.

Automatic Weighing

- Uses an auger filling system, which is especially suitable for garlic powder and other powders with poor flowability.

- Automatically controls the filling amount based on the set weight, with high precision and low error.

- Flexible weighing range, customizable as needed.

Automatic Bag Forming

- Automatically stretches the film, folds, and forms it into bags.

- Supports various bag types such as back-seal, three-side seal, and four-side seal.

- Adjustable bag length and width to fit different packaging sizes.

Automatic Filling

- Works in sync with bag forming; once weighing is complete, garlic powder is automatically filled into the bag.

- Designed with dust prevention to avoid powder spillage or equipment contamination.

- Anti-static features improve filling accuracy and stability.

Automatic Sealing

- The heat sealing system performs both vertical and horizontal sealing.

- Adjustable sealing temperature to suit different laminated film materials.

- Produces smooth, firm, and leak-proof seals, improving shelf life and product appearance.

Automatic Bag Cutting

- After sealing, each bag is automatically cut to form individual packages.

- Supports multiple cutting styles: connected bags, perforated tear lines, or clean straight cuts.

- Some models support easy-tear notches or hanging holes.

Automatic Fault Detection and Alarm

- Equipped with a PLC intelligent control system with self-diagnosis functions.

- Automatically detects issues such as material shortage, film absence, blockages, or abnormal temperature, and triggers alarms with automatic shutdown.

- Enhances operational safety and extends the machine’s service life.

What are the main advantages of the Shuliy garlic powder automatic packing machine?

- Designed for powder: Features an auger feeding system that prevents garlic powder from flying or clogging.

- High automation: Automatically completes feeding, weighing, filling, bag forming, and sealing.

- Excellent sealing performance: Uses high-temperature heat sealing for smooth, firm, moisture-proof, and leak-proof seals.

- Labor-saving: Requires only one operator, significantly improving production efficiency.

- Compatible with various bag types and materials: Supports OPP/CPP, OPP/PE, PET/AL/PE, and other laminated films.

- Compact structure and small footprint: Ideal for small and medium-sized factories, enabling fast and large-volume filling.

Technical specifications of the automatic garlic powder packing machine

| Model | SL-80P |

| Packing Speed | 24-60 bag/min |

| Baglength | 30-150mm |

| Bagwidth | 25-145mm |

| Filling Range | within 80g |

| Power Consumption | 2.2kw |

| Weight | 280kg |

| Dimensions | 650*1050*1750mm |

Note: The specifications above are standard for our machine. We can customize the machine with additional functions or molds based on your specific requirements. We can also recommend a suitable packing machine according to your filling material.

What types of bags can the automatic garlic powder packing machine make?

This machine supports various bag types, including:

- Pillow bag

- Back-seal bag

- Three-sided seal bag

- Four-sided seal bag

The three-sided seal bag is the most commonly used.

How to operate a garlic powder packing machine

Preparation

Check the power voltage, clean the inside of the machine, and prepare all packaging materials.

Turn on the machine

Switch on the vertical packaging machine. Follow the prompts on the control panel to enter the operation interface.

Adjust packaging settings

Set the packaging parameters such as bag size and packaging speed according to your needs.

Place the bags

Put the pre-made bags into the hopper or feeder.

Packaging

Start the machine. The product will be filled into the bags in order. After filling, the bags are sealed and discharged automatically.

Cleaning

Clean any leftover material and wash the machine. Perform regular maintenance.

Precautions for using the garlic powder packing machine

- Read the user manual carefully before operation to ensure correct and safe use.

- Operators should pay attention to their safety and the machine’s safety, and fix any problems promptly.

- Load bags and products according to the machine’s capacity; do not overload.

- Confirm the quality of packaging materials before use to ensure good packaging results.

- After packaging, clean and disinfect the machine to keep materials hygienic.

- Regular maintenance, including inspection, cleaning, and servicing, is essential for the machine’s long life.

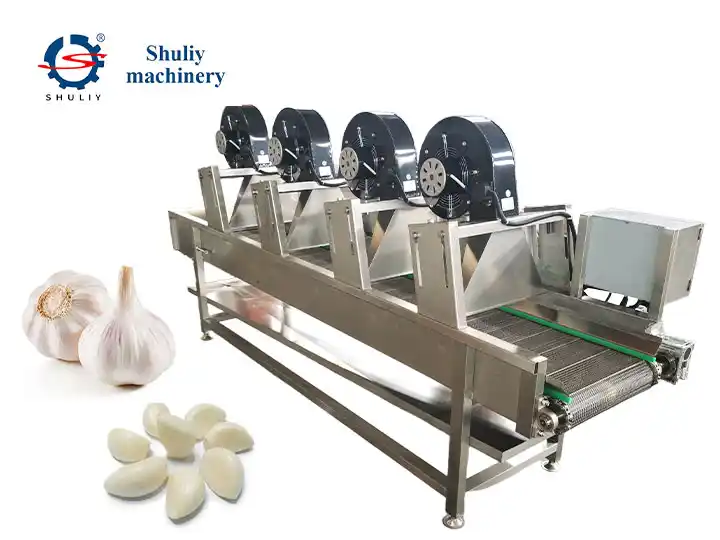

Deep processing of garlic

If your garlic processing involves steps such as root cutting, bulb breaking, peeling, and washing, and you are looking to carry out deep processing of garlic. In that case, we also offer garlic powder production lines and garlic peeling production lines. Feel free to contact us for more information.

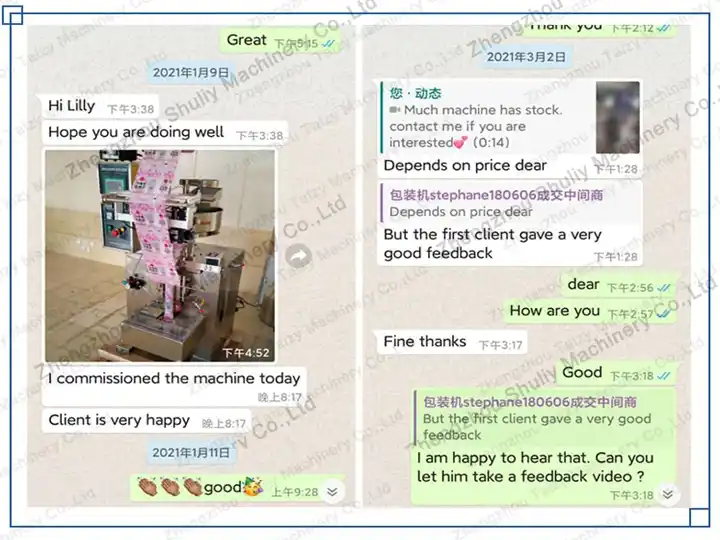

Customer feedback on the garlic powder packaging machine

See what our customers are saying about our garlic powder automatic packing machine.

Hot Product

Onion Root Cutter

The onion root cutter, also called the onion…

Garlic Drying Machine | Garlic Belt Dryer

Garlic dehydrator machine is commonly known as a…

Garlic Air Drying Machine

The garlic air drying machine is a highly…

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Garlic Clove Vacuum Packing Machine

Garlic clove vacuum packing machine with 20L copper-core…

Semi-Automatic Garlic Powder Packing Machine

The semi-automatic garlic powder packing machine is used…

Garlic Powder Grinding Machine

The garlic powder grinding machine applies for grinding…

Garlic Powder Packing Machine | Automatic Garlic Powder Packing Machine

This garlic powder packing machine is a fully…

Garlic Grading Machine

Commercial garlic grading machine use cylinders to classify…