Garlic peeling production line | Garlic processing machine

The garlic peeling production line is very practical for food processors, which mainly includes garlic separator machines, chain-type peeling machines, washing machines, garlic color sorting machines, and garlic screening machines.

Processed garlic has a higher economic value. This production line can separate 1 ton of fresh garlic, and the final products are complete and clean garlic cloves. Using machines to replace labor can save much time and a lot of labor costs.

According to the customer’s needs, we also provide machines for slicing, drying, making garlic powder, and garlic paste after peeling, enabling full-process production and processing.

What steps are there in the garlic peeling production line?

The unpeeled garlic is first sorted by a grading machine to select suitable sizes, then fed into the garlic-breaking machine to separate the bulbs into individual cloves. The separated cloves are transported via a conveyor to the pneumatic peeling machine, where the skins are efficiently removed.

Next, an additional screening process separates any unpeeled or damaged cloves. If needed, the peeled cloves go through a washing machine for further cleaning, and finally, they are automatically weighed and packed by the packaging machine, achieving a continuous and efficient process from whole garlic bulbs to clean, peeled cloves.

Related machines in the garlic peeling processing line

Garlic grading sorting machine

The machine uses a hoist to lift the garlic into the grading cylinder for sorting. This cylinder features round holes of varying diameters that gradually increase in size from left to right. As the garlic moves through the rotating cylinder, it is sorted from small to large according to size. Garlic that falls through the holes is collected in separate containers below, where it can then be manually gathered.

Garlic separator machine

Divide garlic into cloves. The machine squeezes and separates the whole garlic into many small cloves through the four wheels inside, facilitating the peeling in the next step.

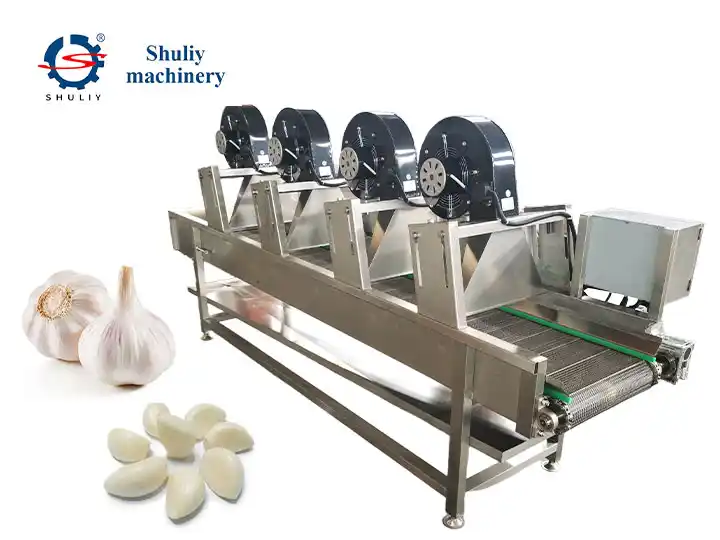

Chain-type peeling machine

The chain-type garlic peeling machine is powered by compressed air and adopts a bin-type peeling structure. A cyclone airflow is installed above the peeling bin. The garlic peeling enters the bin through the chain to realize the separation in the peeling garlic peel bin.

Garlic color sorting machine

The garlic cloves with abnormal colors are identified by the camera, and compressed air sprays them out and falls into the defective product tank, while the good garlic cloves fall into the finished product tank.

Garlic washing machine

The vegetable and fruit washing machine is a kind of cleaning machine. When cleaning, a large number of bubbles will be generated. Water pressure and energy generated when bubbles burst are used to clean dirt and pesticide residues on fruits and vegetables.

This machine is especially suitable for cleaning all kinds of fruits and vegetables, such as apples, potatoes, sweet potatoes, garlic cloves, and so on.

Garlic air drying machine

The garlic air drying machine offers a fast and energy-efficient method to remove surface moisture from garlic cloves. It quickly dries the outer layer without harming the peel, keeping the cloves intact and prepared for subsequent processing or packaging.

Garlic Vacuum Packaging Machine

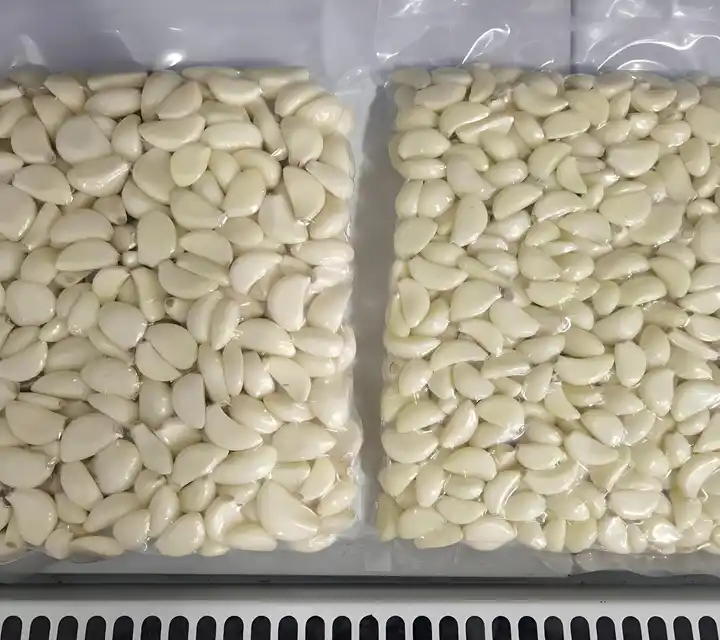

The garlic vacuum packaging machine typically places the garlic into specialized packaging bags, then seals the bag’s opening while extracting the air to ensure no air remains inside. Finally, the bag is heat-sealed to complete the packaging process.

Machine technical parameters

| Item | Specification |

|---|---|

| Capacity Range | Minimum: 500 kg/h (small-scale line) Maximum: 2000 kg/h (large-scale line) |

| Suitable Raw Material | Fresh white garlic, purple garlic, red garlic |

| Total Power | Approx. 16–50 kW |

| Total Footprint | Approx. 15–50 m² |

| Operator Requirement | 2–3 persons |

| Final Product | Clean, whole peeled garlic cloves, which can be further processed into garlic slices, garlic powder, or garlic paste |

Garlic peeling production line – example capacity

| Equipment Combination | Grading Machine | Clove Separator | Chain-type Peeling Machine | Washing Machine | Air Dryer | Vacuum Packaging Machine | Total Line Capacity |

|---|---|---|---|---|---|---|---|

| Small-scale | SL-3 | SL-400 | SL-200 | TZ-2500 | SL-3000 | SL-400/2SD | 500–2000 kg/h |

| Medium-scale | SL-4 | SL-800 | SL-400 | TZ-4000 | SL-4000 | SL-500/2SD | 1000–1500 kg/h |

| Large-scale | SL-5 | SL-800 | SL-1000 | TZ-6000 | SL-6000 | SL-800/2SD | 1500–2000 kg/h |

If you are interested in our machines, we can configure the equipment according to your specific needs.

To learn more about how to set up your peeled garlic production line, please contact us through the chat window on the right.

The raw materials of the garlic peeling production line

Suitable for various types of fresh garlic, such as white garlic, purple garlic, and red garlic. This production line is especially suitable for peeling a large amount of raw garlic, such as 1000 kg.

The necessity of a garlic peeling production line

Garlic peeling is a kind of deep processing of garlic, which is of great value to growers and factories. Many garlic-producing areas are in a good harvest year, but farmers are not happy with the good harvest. Due to various reasons, garlic cannot be sold. A large amount of garlic can only be sold at low prices or rot in the ground. In fact, in addition to raw garlic, garlic can be further processed. Made into processed goods.

- Improving production efficiency to meet large-scale processing needs.

- Ensuring product hygiene and consistent quality.

- Reducing labor costs and saving manpower.

- Supporting multifunctional processing to enhance production.

- Minimizing waste and increasing economic benefits.

What is the economic value of garlic after peeling?

Garlic has many high-value-added products, such as allicin and garlic essential oil. In addition to the development of the international market, the export of garlic condiments to countries with a large demand for garlic, if high-quality products can be produced, then the market and profits are very attractive.

Food seasoning

Garlic is always welcomed by people, so people like the food seasoning made of garlic. After the garlic is peeled, it can be processed into garlic slices, garlic powder, and garlic oil. These natural seasoning foods retain the fragrance and nutrients of garlic, do not contain any chemical additives, are healthy and delicious, and are convenient to eat.

Garlic essential oil (Allicin)

Garlic essential oil is an anti-inflammatory and antiseptic drug, which has an inhibitory effect on a variety of cocci. It can be used as a medicament for clinical use and has high value. It can also be made into feed additives to improve the survival rate.

It is reported that 6.5 kilograms of garlic essential oil can be extracted from each ton of fresh garlic, and the price of garlic essential oil per kilogram is about 300-500, which is of high economic value.

Freeze-dried garlic flakes

Freeze-dried garlic slices are very convenient to eat. They are often placed in instant foods and can be brewed with boiling water to retain the original color and unique taste of garlic. At present, the domestic and foreign markets have a strong demand for freeze-dried garlic.

Deep-processed products of garlic–pickled garlic

Pickled garlic is garlic preserved in vinegar or brine, offering a tangy flavor and extended shelf life.

Tips for preserving garlic

- Peel all the fresh garlic that you bought, and peel it into cloves. Pick out the incomplete garlic and use it for cooking. Prepare a clean container. There should be no drop of water in the container, and keep it dry. Put the garlic in, tighten the lid, and keep it in the refrigerator. In a confined space with low oxygen, garlic will not scorch and sprout even if it is left for a few months.

- Peel the fresh garlic one by one. Be careful not to clean it. Wrap it with plastic wrap and put it in the refrigerator. This will prolong the freshness of the garlic. It will not be damaged after two or three months. Just take it out and wash it when cooking, which is very convenient.

- You can pickle fresh garlic to make soaked garlic, sweet garlic, and laba garlic. The longer the soaking time, the more delicious the garlic will be. There is no need to worry about the loss of nutrition in the garlic. In addition to the spicy taste, garlic is appetizing and food-increasing, but it can also sterilize and reduce inflammation.

Our customers

We warmly welcome your inquiries!

FAQ

What machines are included in a complete peeled garlic production line?

A standard garlic peeling production line includes a garlic grading machine, garlic separating machine, chain-type peeling machine, garlic color sorter, garlic washing machine, air dryer, and vacuum packing machine.

What is the production capacity of the garlic peeling line?

The line can process about 1 ton of fresh garlic per batch, producing clean, undamaged peeled garlic cloves ready for packaging or further processing.

What types of garlic can be processed?

It is suitable for all types of fresh garlic, including white garlic, purple garlic, and red garlic.

How does the garlic peeling process work?

The garlic bulbs are first graded and separated into individual cloves, then conveyed to a pneumatic peeling machine where the skins are removed efficiently using compressed air. The peeled cloves are then sorted, washed, dried, and vacuum packed.

What are the advantages of using a garlic peeling production line instead of manual peeling?

Using machines instead of manual labor saves time, reduces labor costs, improves hygiene and consistency, and enables large-scale processing with minimal waste.

Can the garlic peeling line be customized for different needs?

Yes. According to customer requirements, we can add machines for slicing, drying, garlic powder production, or garlic paste processing, to create a complete garlic processing solution.

How clean is the final peeled garlic product?

The processed garlic cloves are completely clean, free from skins and dirt, and can be further washed and air-dried to ensure food-grade hygiene standards.

What is the economic value of peeled garlic?

Peeled garlic has a much higher market value. It can be processed into garlic flakes, garlic powder, garlic oil, or garlic paste, which are widely used in food, seasoning, and pharmaceutical industries.

What are the power and air requirements for the peeling machine?

The chain-type garlic peeling machine operates using compressed air and requires a stable air supply. Specific power and pressure parameters depend on the chosen model (details can be provided upon request).

Does Shuliy provide installation and after-sales service?

Yes. We offer online technical support, video installation guidance, spare parts supply, and lifelong maintenance service to ensure stable and long-term operation of your garlic processing line.

Hot Product

Onion Root Cutter

The onion root cutter, also called the onion…

Garlic Peeling Machine

A garlic peeling machine is desinged to peel…

Garlic Grading Machine

Commercial garlic grading machine use cylinders to classify…

Semi-Automatic Garlic Powder Packing Machine

The semi-automatic garlic powder packing machine is used…

Garlic Dehydration Machine | Industrial Garlic Drying Oven

Garlic dehydration machine is a hot air circulation…

Garlic Drying Machine | Garlic Belt Dryer

Garlic dehydrator machine is commonly known as a…

Double belts garlic root concave cutting machine

The garlic concave root cutting machine removes the…

Garlic Clove Separating Machine

Garlic clove separating machine is designed to efficiently separate…

Manual Garlic Harvesting Machine

Garlic harvesting machine helps farmers to harvest garlic…