Garlic powder production line

Features at a Glance

The garlic powder production line will get dried garlic powder from raw garlic. It mainly goes through the processes of garlic clove separation, peeling, slicing, cleaning, dehydration, milling, and packaging.

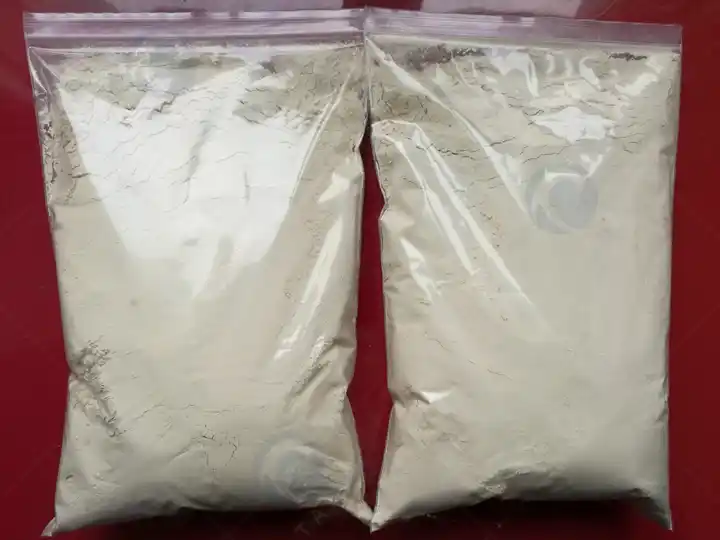

The garlic powder obtained by using the garlic powder processing plant has uniform fineness. And the final garlic powder is packaged, making it easy to transport and store. The machines in this garlic powder production line can also be purchased and used separately.

Why should garlic be processed into garlic powder?

Garlic deep processing refers to garlic products made from raw garlic through certain processing techniques. The deep-processed garlic products include garlic powder, garlic slices, garlic mash, black garlic, garlic oil, and other products. Deep-processed garlic products can increase the utilization rate of garlic and obtain greater economic benefits. The garlic powder made by dehydration and milling has the functions of promoting blood circulation, removing blood stasis, clearing heat, and detoxifying. Compared with garlic, garlic powder is more convenient to eat.

Garlic powder production process

The garlic powder production process is: the garlic cloves are separated, peeled, cleaned, sliced, dehydrated, milled, and packaged.

Separate the whole garlic into individual garlic cloves, and then remove the outer skin of the garlic. Cut the whole garlic into slices, use a dehydrator to dehydrate, grind, and package. Then you can get the finished garlic powder.

Description of garlic powder processing machines

Garlic clove separator machine

A garlic clove separator is a machine used to separate garlic cloves. It mainly imitates the manual action of people rubbing the garlic cloves to separate them garlic cloves. The main purpose of using this machine to separate garlic cloves is to facilitate garlic peeling. This machine is widely used for garlic cloves of different sizes.

Garlic peeling machine

According to the different garlic production capacities, there are two types of garlic peeling machines: small and chain plate peeling machines. Both of these two garlic peeling machines use the same peeling principle, that is, air compression technology peeling. The automatic garlic peeling machine acts on the peeling of dried garlic. And it has no requirements on the variety and size of garlic.

Garlic cleaning machine

The garlic cleaning machine simulates manual cleaning actions through water bath bubble cleaning. It conveys smoothly, speed adjustable, can effectively avoid the cleaning process of touching, knocking, scratches, and other damage to the garlic, improve the efficiency of the work, and change the manual work for mechanized processing.

Garlic slicer machine

The garlic slicer uses a multifunctional root vegetable slicer. It can be used to cut potatoes, cucumbers, taro, yams, ginger, and other raw materials. In addition, the garlic slices cut by this machine are uniform in thickness, smooth in cut surface, and fast in cutting speed. The whole machine adopts food-grade stainless steel, which meets food safety and sanitation standards.

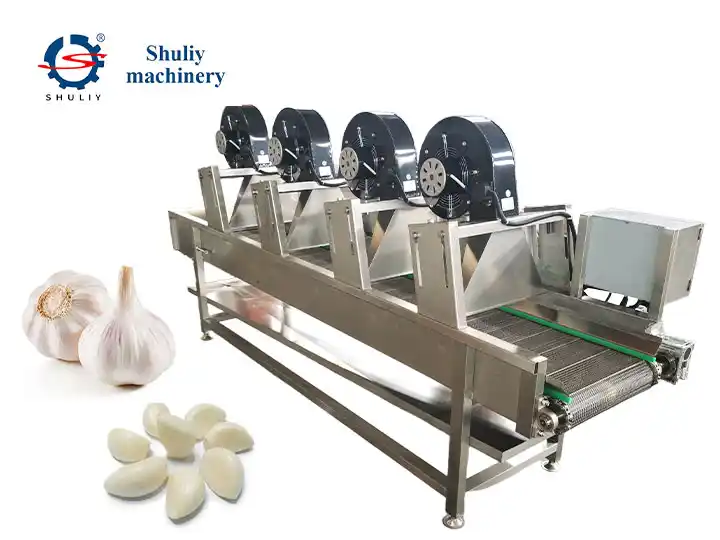

Garlic dehydrator

The garlic dehydrator can use different types of dryers, depending on the dehydration output. It is a multifunctional fruit and vegetable dehydrator. The heating energy can be electricity, gas, biomass particles, waste materials, etc. The garlic dehydrator is operated by an intelligent control panel, and the entire dehydration process is operated by an intelligent control panel. The operation is simple, the drying output is large, and the temperature control is automatically adjusted.

Garlic powder grinding machine

The garlic powder grinding machine mainly grinds garlic into powder by the relative movement between the movable tooth disc and the fixed tooth disc. The fineness of the powder is controllable. The fineness of the powder ground by this machine is uniform. And it has low noise during the grinding process and has a special dust collection device. It is a very popular machine in the food and pharmaceutical industries. This machine can grind garlic, ginger, tea, pepper, and other products.

Garlic powder packaging machine

The garlic powder packaging machine is a semi-automatic weighing and filling powder packaging machine. The machine has the functions of metering, filling, sealing, and transmitting. It can choose a variety of bag-clamping structures according to the customer’s packaging materials and packaging bag form. The machine uses a touchscreen to control its operation of the machine. The packaging process is automated, and the packaging specifications can be adjusted.

Features of garlic powder production line

High Production Capacity

This production line supports a wide range of output capacities, from hundreds to several thousand kilograms per hour, depending on the configuration. Each machine — from the garlic clove separator to the grinding and packaging systems — can be selected according to specific production requirements, ensuring efficient continuous operation and high throughput.

Made of Food-Grade Stainless Steel

All machines are made from SUS304 or SUS316 stainless steel, which meets international food hygiene standards. This material ensures durability, corrosion resistance, and safe contact with food. It also makes cleaning and maintenance easier, guaranteeing long-term stable performance.

Stable Structure and Reliable Performance

The whole line features robust mechanical construction with precise design and low failure rates. The equipment operates smoothly even under heavy load and long working hours, ensuring stable production and consistent product quality.

Intelligent and Easy Operation

Each machine is equipped with intelligent control panels and adjustable speed systems, making it easy for operators to monitor and control the entire process. The system supports automatic temperature and time adjustment during dehydration and packaging, reducing manual intervention and improving efficiency.

Uniform Powder Fineness and High Product Quality

The garlic grinding machine adopts high-speed rotating blades with adjustable mesh sizes (20–120 mesh), ensuring a uniform and fine powder texture. The final garlic powder is dry, smooth, and ideal for use in food manufacturing, seasoning, and pharmaceuticals.

Modular Design — Machines Can Be Used Separately

Each unit (such as the garlic clove separator, peeling machine, washing machine, slicer, dehydrator, grinder, and packaging machine) can be operated independently or combined into a complete production line. This flexible modular design allows customers to customize their setup according to budget and production needs.

Energy-Efficient and Environmentally Friendly

The dehydration system supports multiple heating sources such as electricity, gas, biomass pellets, or waste heat. The intelligent temperature control reduces energy waste while maintaining drying efficiency, making it both cost-effective and eco-friendly.

Compact Layout and Easy Maintenance

The line is designed for compact installation, saving workshop space. Most components are designed for easy disassembly and cleaning, which minimizes downtime and maintenance costs

High Cost Performance

Compared with imported processing systems, this line offers excellent performance at a lower investment cost. Its stable operation, easy maintenance, and long service life provide significant economic benefits to garlic processing factories.

Widely Applicable

The garlic powder production line can also process other materials such as ginger, onion, chili, turmeric, and black pepper, further increasing the utilization rate and business flexibility.

Uses of garlic powder

Garlic powder is a highly popular natural seasoning and functional ingredient in the global market. It is widely used in food, catering, health, agriculture, and other industries—especially in regions like Europe, the United States, Southeast Asia, and the Middle East.

Food industry

- Seasoning Blends: Commonly used in garlic salt, garlic pepper, BBQ rubs, and spice mixes such as Italian seasoning or Mexican spice blends. It is a major export product.

- Ready-to-Eat Foods: Added to pizza, burgers, fried chicken, French fries, instant noodles, soups, salad dressings, and more to enhance flavor.

- Frozen Foods: Widely used in pre-cooked meals. Garlic powder is a key seasoning in many frozen dishes sold in supermarkets across the U.S. and Europe.

Restaurant chains

- Popular among large fast food brands (like KFC or Subway), Middle Eastern restaurants, and Latin BBQ chains.

- Used in bulk for seasoning and marinating, replacing fresh garlic to save prep time and keep taste consistent.

Health supplements

- In Western countries, garlic powder or extract is made into capsules and tablets, promoted for heart health, antibacterial effects, antioxidant properties, and cholesterol control.

Animal feed industry

- In Europe and Latin America, garlic powder is increasingly used as a natural alternative to antibiotics in animal feed. It helps boost immunity and improve digestion in poultry, pigs, and fish.

Organic and eco-friendly agriculture

- Used to make natural pesticides and disinfectants, ideal for organic farms. It helps reduce the use of chemical agents and supports environmentally friendly farming.

Best-selling countries for garlic powder

Garlic powder is most popular in the following countries and regions, with high market demand and wide applications:

- United States

- India

- Brazil

- Mexico

- Germany

- Japan

- Middle Eastern Countries (e.g., Saudi Arabia, UAE)

- ……

Main machine model reference list

Garlic clove separator machine

- Model: SL series

- Capacity: 400 – 1000Kg/h

- Power: 1.1kw or 2.2kw

- Voltage: 380V

- Dimension: According to the specific technical specifications

Garlic peeling machine

- Model: SL-200; SL-400; SL-600; SL-1000

- Voltage: 110-220-380V

- Weight: 150KG; 250KG; 350KG; 500KG

- Output: 200kg/h; 400kg/h; 600kg/h; 1000kg/h

- Size: 130*55*140CM; 162*55*140CM; 182*60*140CM; 280*98*170CM

Garlic cleaning machine

- Capacity: 500 – 2000Kg/h

- Material: SUS304

- Power: Customizable

- Size: According to the specific technical specifications

Garlic slicer machine

- Model: SL-300

- Dimension:100*73*95CM

- Capacity: 300kg/h

- Material: SS304/SS316

- Weight: 75KG

- Power:0.75KW

Garlic dehydrator

- Model: SL series

- Capacity: 300 – 8000Kg/h

- Power: Customizable

- Size: According to the specific technical specifications

Garlic powder grinding machine

- Model: SL-B series

- Capacity: 20 – 3000Kg/h

- Crushing fineness: 20-120 mesh

- Motor power: 2.2-37KW

- Spindle speed (R/Min): Refer to the technical parameter

- Feeding size: 6-15mm

Garlic powder packaging machine

- Packing speed: 24-60 bag/min

- Bag length: 30-150mm

- Bag width: 25-145mm

- Filling range: within 80g

- Power consumption: 2.2kw

- Dimensions: 650*1050*1750mm

Garlic Powder Production Line – FAQ

What is the production capacity of the garlic powder line?

Depending on the configuration, the output ranges from 400 kg/h to 8000 kg/h. Each machine can be customized to meet different production needs, from small to large-scale operations.

What material is used for the equipment? Is it food-grade?

All machines are made of SUS304 or SUS316 food-grade stainless steel, which is corrosion-resistant, easy to clean, and fully compliant with international food hygiene standards.

Can this production line process other materials besides garlic?

Yes. It can also be used to process ginger, onion, chili, turmeric, black pepper, and other root or spice materials, making it a versatile investment.

Can the fineness of the garlic powder be adjusted?

Yes. The powder grinder allows adjustable mesh sizes from 20 to 120 mesh, enabling the production of both coarse and fine garlic powder.

What are the heating methods for the dehydration machine?

The dehydrator supports multiple heating sources, such as electricity, gas, biomass pellets, or waste heat, which can be selected according to local energy availability.

Is the operation complicated? Do I need trained technicians?

Not at all. The line uses intelligent control panels for temperature, time, and speed adjustment. After basic training, operators can easily manage the entire process without needing a specialized technician.

Can the machines be purchased separately?

Yes. Each machine — including the garlic clove separator, peeler, slicer, washer, dehydrator, grinder, and packaging machine — can be sold separately or as part of a complete production line.

What are the main applications of the final garlic powder?

Garlic powder is widely used in food seasoning, fast-food chains, health supplements, animal feed, and organic agriculture. It is a high-demand natural spice in global markets.

Is the equipment easy to clean and maintain?

Yes. The machines feature a compact structure and detachable design, allowing quick cleaning and low maintenance costs while ensuring long-term stable performance.

Can the garlic powder production line be customized?

Absolutely. Shuliy offers customized solutions based on your required capacity, plant layout, voltage, packaging type, and heating source to ensure optimal production efficiency.

Cooperate with us

If interested, pls just contact us for details via WhatsApp directly: https://wa.me/+8619139761487

Hot Product

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Garlic peeling production line | Garlic processing machine

The garlic peeling production line is very practical…

Garlic Clove Separating Machine

Garlic clove separating machine is designed to efficiently separate…

Onion Root Cutter

The onion root cutter, also called the onion…

Ginger Garlic Paste Making Machine

Automatic ginger garlic paste making machine is widely…

Garlic Dehydration Machine | Industrial Garlic Drying Oven

Garlic dehydration machine is a hot air circulation…

Garlic Air Drying Machine

The garlic air drying machine is a highly…

Manual Garlic Harvesting Machine

Garlic harvesting machine helps farmers to harvest garlic…

Garlic Peeling Machine

A garlic peeling machine is desinged to peel…