Машина для калибровки чеснока

The commercial garlic grading machine uses round holes on the drum to classify garlic. It offers high sorting accuracy without damaging the bulbs, with a capacity of 3–6 tons per hour.

This machine can be used for screening and grading various materials, such as garlic, onion, apples, potatoes, and others.

The commercial garlic sorting machine is mainly composed of a hoist and a sorting machine, and the size of the sieving machine can be customized. The entire machine is made of silicone material, allowing it to directly contact the fruit without damaging it, as it is round and smooth.

This grading machine has been exported to Pakistan, Saudi Arabia, India, Thailand, Italy, and other countries.

Особенности машины для сортировки чеснока

- This commercial garlic sorting machine can classify a variety of round materials. Such as potatoes, walnuts, hawthorn, apples, onions, and other round or oval materials.

- Размер оценки можно настроить.

- Коммерческое оборудование для сортировки чеснока в основном состоит из подъемника и сортировочного оборудования, с высокой степенью автоматизации.

- Конвейерная лента машины оснащена бесступенчатой регулировкой скорости, что позволяет свободно контролировать скорость транспортировки чеснока.

- Эта барабанная машина для сортировки фруктов использует раструбную сортировку, что делает расстояние между сортировочными отверстиями более стандартизированным.

- The screening part of the drum adopts silica gel to directly contact the raw materials without damaging them.

- With high sorting accuracy, the machine can grade garlic into standard sizes of 4.5 cm, 5.0 cm, 5.5 cm, 6.0 cm, 6.5 cm, and above 6.5 cm. Custom sizes are also available upon request.

- The grading screen is made of PVC mesh, and the feeding table is equipped with brushes to ensure the garlic is not damaged.

- The garlic grading machine offers multiple grading levels. Depending on the processing scale, you can choose 2, 3, 4, or 5 grades, which greatly improves primary garlic processing efficiency.

Принцип работы коммерческой машины для сортировки чеснока по классам

The machine uses a lifting conveyor to feed garlic into the grading machine. The garlic moves along the conveyor into a grading drum with round holes of increasing sizes. During sorting, garlic falls gradually into the corresponding collection containers by size and then passes through the discharge outlet into packing bags, achieving automated grading and collection.

Structure of the garlic sorting machine

The garlic sorting machine mainly consists of a lifting system, a conveying system, a grading device, a collection system, and a control system.

Lifting system

Machine: Belt elevator

Function: Lifts garlic from the ground or feed inlet to the working height of the grading machine, ensuring continuous feeding

Conveying system

Machine: Chain conveyor

Function: Evenly transports garlic to the grading drum or grading wheel

Grading device

Machine: Round-hole drum sieve

Function: Holes increase in size from small to large, sorting garlic by size

Collection system

Machine: Hopper

Function: Collects garlic of different sizes separately

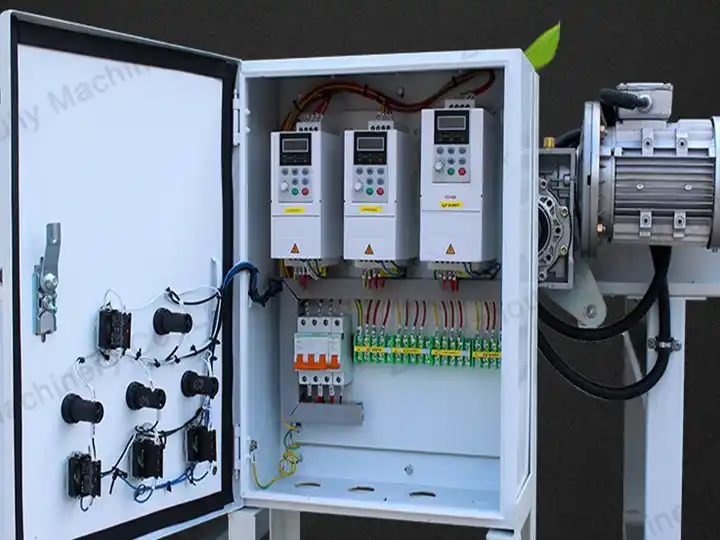

Control system

Machine: PLC intelligent control box

Function: Controls the entire machine operation, including motor start/stop and conveyor speed adjustment

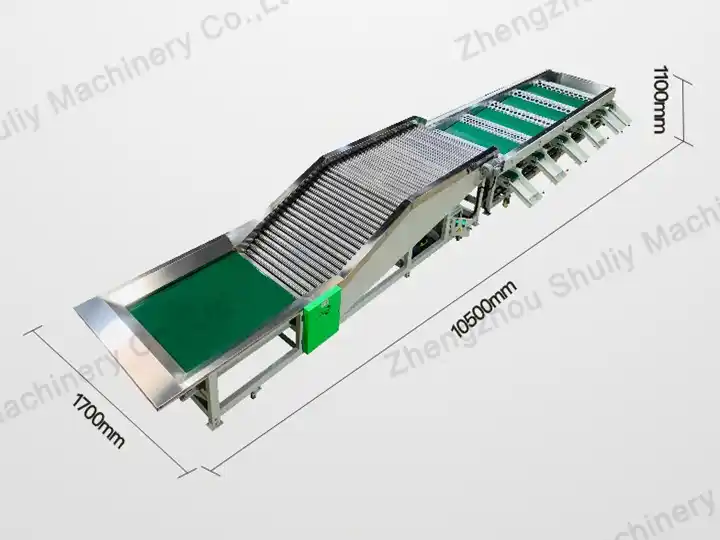

Параметры коммерческой машины для сортировки чеснока по классам

| Модель | SL-3 | SL-4 | СЛ-5 |

| Власть | 1,1 кВт | 1,1 кВт | 1,1 кВт |

| Напряжение | 380В | 380В | 380В |

| Емкость | 1-2t/h | 3-4т/ч | 5-6t/h |

| Размер | 3505*955*925mm | 8000*1400*800mm | 10500*1700*1100mm |

If you have more requirements, we can customize the machine according to your needs, such as power voltage, plug type, sieve hole size, or more grading levels. You are welcome to contact us for consultation.

Garlic grading machine ROI analysis

After purchasing a garlic grading machine, it is important to consider its return on investment (ROI). The ROI can be evaluated from several aspects: cost input, increased output, labor savings, and added product value. Here, we assume a small to medium-sized garlic paste processing factory with a daily processing capacity of about 4 tons. The above prices are for reference only and do not reflect actual purchase costs.

| Item | Value |

|---|---|

| Equipment investment cost | $10,000 |

| Installation and commissioning | $1,000 |

| Daily processing capacity | 4 tons |

| Garlic price | $1,000/ton (raw material cost, not profit, used for output calculation) |

| Increased output efficiency | 5% |

| Labor savings | 2 people × $10/day × 25 days/month = $500/month |

| Operating cost | $100/day × 25 days/month = $2,500/month |

Revenue from increased output

- Original daily output value: 4 tons × $1,000 = $4,000

- Efficiency increase 5% → Additional output value: $4,000 × 5% = $200/day

- Monthly added value (25 days): $200 × 25 = $5,000

Labor savings

- Monthly labor cost savings: $500

Monthly net profit

- Monthly added value + labor savings – operating cost

- $5,000 + $500 – $2,500 = $3,000/month

Investment payback period

- Total investment: $10,000 + $1,000 = $11,000

- Monthly net profit: $3,000

- Payback period = $11,000 ÷ $3,000 ≈ 3.7 months

Conclusion

Under these assumptions, the garlic grading machine can pay back in about 4 months. After that, the increased output and labor savings almost entirely convert to profit, giving a very high return on investment.

Garlic deep processing

Shuliy has over ten years of production and sales experience and offers a full range of garlic processing machines, including garlic clove splitters, garlic peelers, garlic washers, and more. We can also provide complete solutions for garlic powder and garlic paste production lines. You are welcome to contact us through the pop-up chat for more information.

Горячий продукт

Чесночный режущий станок

Слайсер для чеснока высокой производительности, многофункциональный, простое управление…

Станок для нарезки чеснока

Эта машина для нарезки чеснока проста в эксплуатации…

Машина для очистки чеснока

Машина для очистки чеснока предназначена для очистки…

Чесночный порошковый дробильный станок

Машина для измельчения чесночного порошка предназначена для помола…

Чесночный корневой стебель резки машины

Машина для обрезки корней и стеблей чеснока предназначена для…

Ручной сборочный станок для чеснока

Комбайн для уборки чеснока помогает фермерам собирать чеснок…

Сушильный станок для чеснока | Лентяй-чесночная сушилка

Машину для сушки чеснока обычно называют…

Очистительная машина чеснока

Полностью автоматическая высокопроизводительная многофункциональная машина для мойки чеснока,…

Линия по производству очистки чеснока | Машина для переработки чеснока

Линия по очистке чеснока очень практична…