How to Choose a Peeled Garlic Production Line Suitable for Your Business?

As the food processing industry’s demand for peeled garlic grows, more companies are investing in peeled garlic production lines. However, with many models and functions on the market, how do you choose the right peeled garlic production line for your business?

This article will provide guidance based on production capacity, automation level, quality standards, and maintenance costs, helping you find the most efficient garlic peeling production line for your operation.

Focus 1: Based on Production Capacity

Peeled garlic production lines come in small, medium, and large sizes. When choosing, first determine your daily or hourly processing volume:

- Small equipment: Suitable for small workshops or startups, with a capacity of 100–300 kg/h. It takes up little space and has a low investment cost.

- Medium equipment: Suitable for medium-sized processing plants, with a capacity of 300–800 kg/h. Offers a certain level of automation to save labor costs.

- Large equipment: Suitable for industrial production or export processing, with a capacity of over 1000 kg/h. Fully automated operation improves production efficiency.

Whether you need a compact garlic peeling production line or a high-output peeled garlic production line, understanding your production goals helps make the best investment.

Focus 2: Automation

- Fully automatic equipment: Automatically cleans, peels, grades, and packages garlic. Greatly reduces labor costs and is suitable for large-scale production.

- Semi-automatic equipment: Some processes require manual operation. Lower cost and suitable for small to medium-sized processing plants.

- Manual-assisted equipment: Mainly operated by hand. Suitable for small workshops or trial production.

Higher automation increases production efficiency but also raises initial investment. Choose a peeled garlic production line with the right automation level for your budget and output needs.

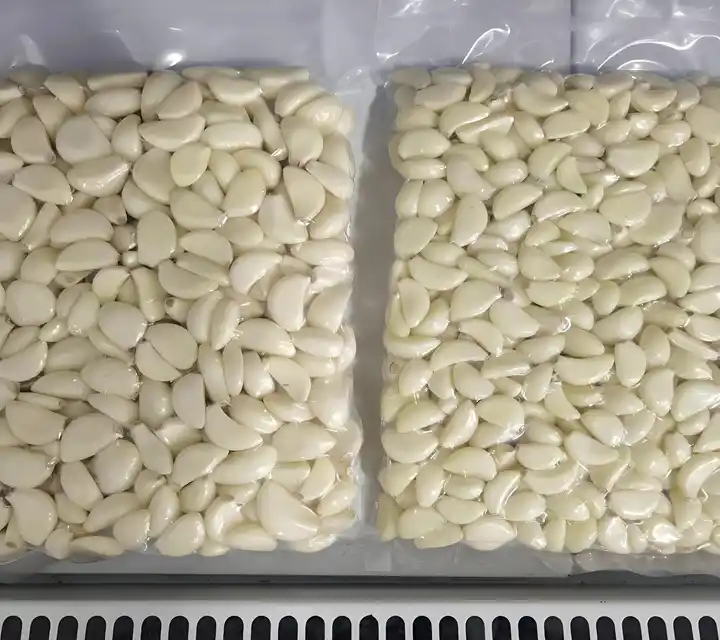

Focus 3: Peeling Quality and Loss Rate

- High-quality equipment can ensure a peeling rate of over 95%, keeping garlic cloves intact and undamaged.

- Low-quality machines may cause broken or partially peeled cloves, affecting the appearance and taste of the final product.

When purchasing, check the manufacturer’s sample tests or customer cases to ensure stable and reliable peeling performance from your garlic peeling production line.

Focus 4: Equipment Material

Food-grade stainless steel is the preferred material because it is corrosion-resistant and easy to clean.

Equipment that meets safety standards not only ensures food quality but also reduces business liability risks.

Choosing a peeled garlic production line made from stainless steel ensures hygiene, durability, and long-term performance.

Focus 5: Maintenance Cost and After-Sales Service

A peeled garlic production line requires regular maintenance during long-term operation. Consider the following:

- Are spare parts easy to replace?

- Are repair costs reasonable?

- Does the manufacturer provide timely after-sales service and technical support?

Reliable after-sales support ensures your garlic peeling production line runs efficiently with minimal downtime.

Focus 6: Future Business Development

- Can the equipment support capacity expansion or upgrades?

- Is it compatible with different sizes of garlic?

- Can it be integrated with other production lines, such as packaging lines?

If you plan to expand production, consider a peeled garlic production line that can grow with your business.

Recommended Peeled Garlic Production Line

If you are looking for a reliable peeled garlic production line, we highly recommend Shuliy’s peeled garlic equipment.

As a professional manufacturer of complete garlic processing solutions, Shuliy offers products with the following key advantages:

- High peeling efficiency: Using dry air-flow peeling technology, the equipment achieves a high peeling rate with minimal damage, suitable for large-scale processing.

- Food-grade material and structure: Made entirely of stainless steel, meeting food safety standards, and easy to clean and maintain.

- Various capacity options: Shuliy provides models ranging from dozens to several hundred kg/h, allowing flexible choices according to your business scale.

- Excellent after-sales service: The company offers a complete system for design, manufacturing, and sales, providing full support from equipment selection and factory testing to installation and commissioning.

By choosing Shuliy’s peeled garlic production line, you gain a cost-effective and durable solution for garlic processing.

Components of the Peeled Garlic Production Line

The main equipment includes a garlic clove separator, chain-type peeling machine, garlic washing machine, garlic air dryer, garlic color sorter, and garlic vacuum packing machine.

Of course, Shuliy can also customize machines according to your specific needs, ensuring your garlic peeling production line perfectly matches your production goals.