Garlic Clove Separating Machine

The garlic clove separating machine is designed to efficiently separate garlic bulbs into whole cloves. It uses standard soft rollers to simulate the hand-peeling process, ensuring the cloves remain intact and undamaged, and is suitable for garlic of various sizes. The clove separation rate can reach around 98%.

Compared with traditional manual peeling, which is slow, inefficient, and often damages the cloves, causing them to release water, the garlic clove separator provides a professional solution. It is an ideal tool for garlic farmers, processing companies, restaurants, and canteens.

Shuliy’s single garlic clove separator has a capacity ranging from 400 to 1,500 kg/h. For smaller capacities, the machine can be customized upon request. For labor-saving purposes, we can also provide a complete garlic clove processing line to further improve efficiency.

This medium and small-sized garlic clove separator is popular in the Middle East, Europe, and Asia, including countries such as Saudi Arabia, Poland, India, and Pakistan, etc.

Advantages of garlic clove separating machine

- High splitting rate. The garlic separating ratio is above 98%.

- High production efficiency. The output of the machine can reach up to 1500kg/h.

- Hygienic and durable material. full stainless steel and durable.

- Easy to operate and easy to maintain, and clean, with a low failure rate.

- Energy-saving and labor-saving.

- Space-saving. The appearance of the equipment is exquisite, the internal structure is compact, and the coving area is small and easy to use.

- Environmental protection, energy saving, no pollution to the environment, and no waste of raw materials.

- Highly adaptable. The roller spacing can be adjusted to handle garlic bulbs of different sizes.

- Efficient clove separation. Equipped with a working fan that blows away garlic skins, stems, and separates the cloves.

- Clove protection. Soft rubber rollers simulate hand peeling without damaging the clove skins.

Garlic bulb breaker parameter

| Model | Power | Voltage | Productivity | Dimension | Weight |

| SL-400 | 1.1kw | 380V | 400kg/h | 690*580*950mm | 80kg |

| SL-800 | 2.2kw | 380V | 800kg/h | 840*940*1320mm | 260kg |

Apart from SL-400 and SL-800, we also supply other machine models with different outputs for options. The model of the garlic clove separating machine is named after the productivity of the machine. If customers have special demands, we are able to provide tailored services.

Garlic separating machine working principle

The garlic clove separator uses high-peeling rubber discs and soft rollers to simulate the manual clove separation process. After the garlic bulbs are fed into the machine, the adjustable rollers gently roll and press the bulbs, separating the cloves without causing damage. The built-in fan blows away the excess garlic skins, leaving clean, intact cloves. This machine is designed to efficiently handle garlic of different sizes, making the subsequent peeling process much easier.rk.

How to operate the garlic clove separator

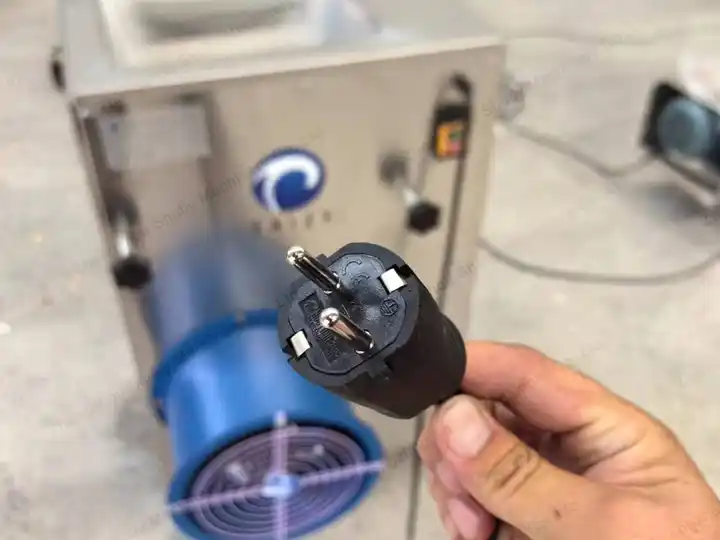

- Prepare the machine: Ensure the machine is clean, properly assembled, and connected to the correct power supply.

- Adjust the rollers: Set the roller spacing according to the size of the garlic bulbs to ensure proper separation.

- Feed the garlic: Place garlic bulbs into the feeding inlet of the machine.

- Start the machine: Turn on the machine. The soft rollers will gently roll and press the garlic bulbs, separating the cloves.

- Remove garlic skins: The built-in fan blows away the loose garlic skins and stems.

- Collect the cloves: Gather the separated, intact garlic cloves from the output area.

- Clean and maintain: After operation, clean the machine and check for any wear or issues before the next use.

Garlic clove processing line

he garlic clove processing line is a complete set of automated equipment designed to efficiently separate garlic bulbs into whole cloves. The line typically includes cleaning, air-drying, peeling, clove separation, and fan-based skin removal, achieving fully automated operation. It offers high efficiency, a high clove separation rate, and minimal damage to the cloves. This line is suitable for garlic farmers, processing companies, restaurants, and food processing factories, significantly reducing labor, improving clove separation efficiency, and enhancing product quality.

Garlic cleaning machine

Removes dirt and impurities from the surface of garlic bulbs.

Garlic air drying machines

The washed garlic bulbs can be air-dried to remove surface moisture, which facilitates the subsequent clove separation process.

Garlic clove separator

Separates garlic bulbs into whole cloves with a high separation rate.

Conveying Eequipment

Automatically transports garlic bulbs and cloves between different processing stages, improving efficiency.

Garlic clove separator shipping cases

Shuliy provides one-stop shipping services. All machines are wrapped in protective film to prevent water and moisture damage, and exported in wooden crates to ensure they arrive at the customer’s location in perfect condition.

Related Machines about garlic bulb breaking machine

A garlic separator machine can be combined with a garlic peeling machine, a garlic slicer, and others to form a garlic peeling processing line. Our company can provide tailor-made products and services according to the different needs of customers.

Hot Product

Garlic Powder Grinding Machine

The garlic powder grinding machine applies for grinding…

Garlic Grading Machine

Commercial garlic grading machine use cylinders to classify…

Double belts garlic root concave cutting machine

The garlic concave root cutting machine removes the…

Semi-Automatic Garlic Powder Packing Machine

The semi-automatic garlic powder packing machine is used…

Garlic Peeling Machine

A garlic peeling machine is desinged to peel…

Onion Root Cutter

The onion root cutter, also called the onion…

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Garlic Planting Machine

The garlic planting machine is an agricultural tool…

Garlic Clove Separating Machine

Garlic clove separating machine is designed to efficiently separate…