Máquina de molienda de polvo de ajo

The garlic powder grinding machine is a multifunctional grinder that can quickly grind dried garlic slices into garlic powder. It is widely used in the food, feed, chemical, pharmaceutical, and agricultural industries.

This industrial garlic powder grinder is made of food-grade stainless steel, which is corrosion-resistant, easy to clean, and ensures no contamination of garlic powder. With a high rotating speed, it can grind fine garlic powder of 60–120 mesh, with a capacity of 10–3000 kg/h.

It is mainly used for grinding dry materials such as spices, pepper, chili, ginger, garlic, coffee beans, cocoa beans, herbs, tea leaves, wheat, chemical raw materials, and dried fruits. High-oil materials such as sesame, walnut, peanut, almond, and melon seeds cannot be ground alone. For processing, they should be mixed with low-oil or oil-free materials, with the oil content kept below 25%. For large, high-oil materials, a crusher or stainless-steel coarse crusher should be used first, and then the material can be processed by the superfine grinding machine.

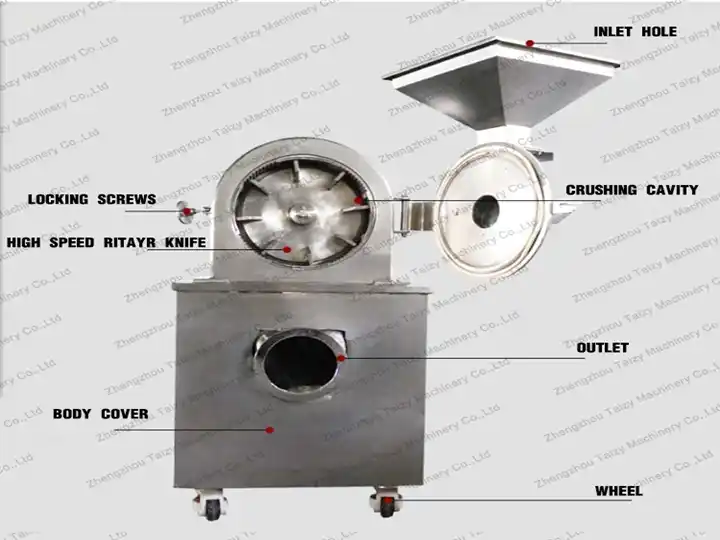

Vipengele vya mashine ya kusaga unga wa vitunguu

A garlic powder grinder generally consists of a hopper, a high-speed rotating blade, a crushing cavity, locking screws, a body cover, an outlet, wheels, and manual and intelligent control buttons.

Hopper: Holds and guides garlic slices into the grinding chamber.

Ncha inayozunguka kwa mwendo kasi: Inakata, inabomoa, na inafinyanga vitunguu kuwa unga mzito.

Kaviti ya kusaga: Inatoa nafasi ambapo vitunguu vinasagwa kwa ufanisi.

Locking screws: Secure parts in place to ensure safe operation.

Kifuniko cha mwili: Kinatulinda vipengele vya ndani na kuzuia vumbi kutoroka.

Outlet: Allows the finished garlic powder to exit the machine.

Magurudumu: Wezesha kusogea kwa urahisi na kubebeka kwa mashine ya kusaga.

Vitufe vya udhibiti wa mwongozo na akili: Dhibiti modi za uendeshaji na vitendo vya start/stop.

Kanuni ya kazi ya mashine ya kutengeneza unga wa vitunguu

The garlic powder grinding machine works through the high-speed rotation of a blade disc or tooth disc against fixed components, achieving crushing by impact, shear, and friction. The material enters the grinding chamber through the hopper and is discharged automatically under centrifugal force. The particle size can be adjusted by changing sieves with different apertures.

The machine features a simple structure, stable operation, and low noise. Made of stainless steel, it meets GMP standards, is easy to clean, and is ideal for efficient grinding of garlic powder and similar materials.

Faida za mashine ya kusaga unga wa tangawizi

Mifano mingi, anuwai ya uwezo

- Mifano: SL-15B hadi SL-100B

- Uwezo: 10–3000 kg/h

- Programu: Viwanda vya usindikaji wa vyakula, viwanda vya viungo, mashirika ya usindikaji wa kina ya mazao ya kilimo

Muundo wa kusaga wenye ufanisi

- Muundo wa kusaga wima

- Ncha za kuzunguka/kipande cha meno zinagonga, kunata, na kusaga dhidi ya diski zilizowekwa

- Ukubwa wa chembe: 60–120 mesh, unaobadilishwa kwa kubadilisha sieves

Nguvu ya juu ya kuendesha

- Mwendo wa spindle: 1500–6000 r/min

- Nguvu ya motor: 2.2–37 kW

- Uendeshaji thabiti, kelele ndogo, inafaa kwa uzalishaji wa kuendelea

Chuma cha pua daraja la chakula 304

- Isiyochakaa, haina kutu

- Inakidhi viwango vya GMP vya usindikaji wa vyakula

- Unga wa vitunguu unahifadhi rangi ya asili na harufu safi

Uendeshaji rahisi & matengenezo

- Utoaji rahisi, utoaji wa moja kwa moja

- Rahisi kufunga na kusafisha

- Inafaa kwa uzalishaji unaobadilisha malighafi mara kwa mara

Ndogo na yenye kubadilika

- Vipimo: 550×400×850 mm hadi 1350×1000×2100 mm

- Uzito: 150–1580 kg

- Inaweza kuchaguliwa kwa uhuru kulingana na uwezo na nafasi ya warsha

Vigezo vya mashine ya kutengeneza unga wa vitunguu ya chuma cha pua

| Aina | SL-15B | SL-20B | SL-30B | SL-40B | SL-50B | SL-60B | SL-80B | SL-100B |

| Uwezo wa uzalishaji (KG/H) | 10-50 | 60-150 | 100-300 | 160-800 | 300-1000 | 500-1500 | 600-2000 | 800-3000 |

| Ukubwa wa ulaji(mm) | 6 | 6 | 10 | 12 | 15 | 15 | 15 | 15 |

| Ubora wa kusagwa (Mesh) | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 |

| Nguvu ya Magari (KW) | 2.2 | 4 | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Kasi ya spindle (R/Mik) | 6000 | 4500 | 3800 | 3400 | 2900 | 2900 | 2000 | 1500 |

| Uzito (KG) | 150 | 280 | 340 | 450 | 600 | 900 | 1250 | 1580 |

| Ukubwa (MM) | 550*400*850 | 600*550*1250 | 700*600*1450 | 900*800*1550 | 1050*850*1750 | 1100*900*1880 | 1200*950*2000 | 1350*1000*2100 |

Jinsi ya kusaga vipande vya vitunguu vilivyokaushwa hadi kuwa unga?

- Kula: Mimina vipande vya vitunguu vilivyokaushwa sawasawa kwenye hopper.

- Kukanda: Vipande vya vitunguu huingia kwenye chumba cha kukanda, ambapo visu vya kasi ya juu vinavyozunguka huathiri, kukata na kusaga kuwa unga.

- Kuchuja & kutoa: Unga wa vitunguu uliochanganywa hupita kupitia sieve kwa ajili ya uainishaji. Ukubwa wa chembe unaweza kurekebishwa kwa kubadilisha sieve, kwa kawaida na ukubwa wa malisho wa 6–15 mm.

- Ukusanyaji: Unga wa vitunguu uliohitimu huachiliwa kutoka kwenye tundu na kukusanywa kwenye chombo au mashine ya kujaza. Shuliy hutoa semi-automatic Mchinjio wa vitunguu vya mchuzi wa juu, wa kazi nyingi, rahisi kudhibiti… Mashine za kujaza unga wa vitunguu kiotomatiki kamili.

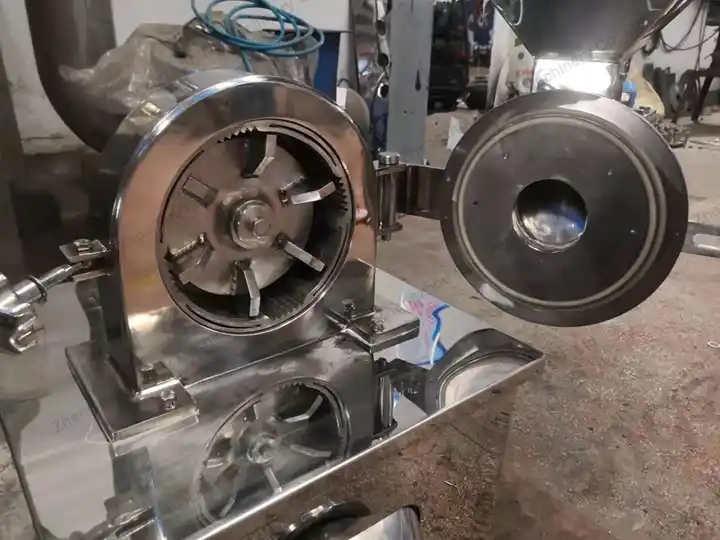

Onyesho la muundo wa ndani

Onyesho la usafirishaji

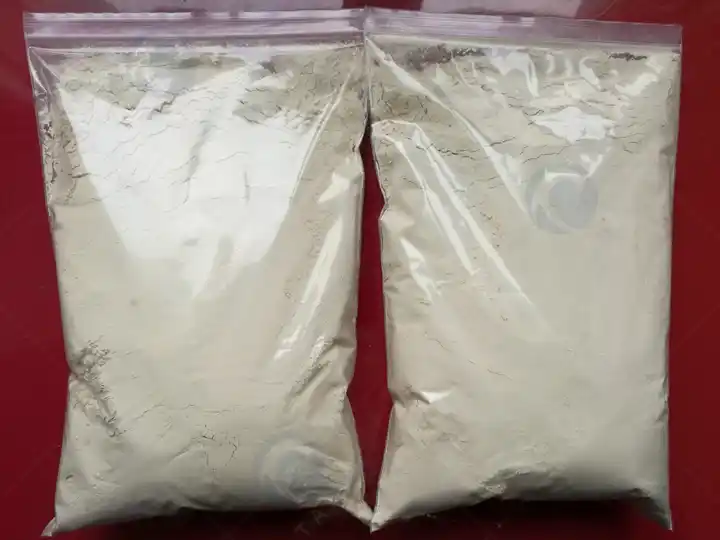

Onyesho la athari ya kusaga

Mstari wa uzalishaji wa unga wa vitunguu

Linjé av förskreddarskydda vitlökspulver tillverkningsprocessen för behandling av färsk vitlök till torrt vitlökspulver. Huvudstegen inkluderar klyftseparerering, skalning, skivning, tvättning, torkning, malning och förpackning. Vitlökspulvret som tillverkas i fabriken har en enhetlig finhet. Slutprodukten är förpackad för enkel transport och lagring.

Bidhaa Moto

Maskin för att skiva vitlök

Mashine hii ya kukata vitunguu saumu ni rahisi kuitumia…

Mikanda miwili vitunguu mizizi concave kukata mashine

Mashine ya kukata mzizi wa konkavu ya vitunguu inaondoa…

Mashine ya Kukata Viazi vya Kitunguu saumu | Kichakataji cha Kitaaluma cha Kitunguu saumu

Mashine ya kung’unya vitunguu saumu ya aina ya mnyororo imetengenezwa mahsusi…

Mstari wa uzalishaji wa unga wa vitunguu

Mstari wa uzalishaji wa unga wa vitunguu saumu hasa unajumuisha vitunguu saumu…

Maskin för att skiva vitlök

Kata vitunguu yenye utendaji mzuri, yenye kazi nyingi, rahisi kudhibiti…

Mashine ya Kumenya Vitunguu

Mashine ya kupolia vitunguu imeundwa kuondoa…

Máquina de clasificación de ajos

Mashine ya kupangilia vitunguu ya kibiashara inatumia silinda kupangilia…

Maskin för vakuumförpackning av vitlöksklyftor

Mashine ya kufunga vipande vya kitunguu kwa utupu yenye kiini cha shaba 20L…

Maskin för packning av vitlökspulver med halvautomatisk funktion

Mashine ya nusu-kiotomatiki ya upakiaji wa unga wa vitunguu saumu inatumiwa…