Máquina de Clasificación de Ajo

The commercial garlic grading machine uses round holes on the drum to classify garlic. It offers high sorting accuracy without damaging the bulbs, with a capacity of 3–6 tons per hour.

This machine can be used for screening and grading various materials, such as garlic, onion, apples, potatoes, and others.

The commercial garlic sorting machine is mainly composed of a hoist and a sorting machine, and the size of the sieving machine can be customized. The entire machine is made of silicone material, allowing it to directly contact the fruit without damaging it, as it is round and smooth.

This grading machine has been exported to Pakistan, Saudi Arabia, India, Thailand, Italy, and other countries.

Características de la máquina clasificadora de ajo.

- Esta máquina clasificadora de ajo comercial puede clasificar una variedad de materiales redondos. Como patatas, nueces, espino, manzanas, cebollas, y otros materiales redondos u ovalados.

- El tamaño de la calificación se puede personalizar.

- La maquinaria comercial de clasificación de ajo está compuesta principalmente por un elevador y equipos de clasificación, con un alto grado de automatización.

- La cinta transportadora de la máquina adopta una regulación de velocidad continua, que puede controlar libremente la velocidad de transporte del ajo.

- Esta máquina clasificadora de frutas de tipo tambor adopta una clasificación de boca de campana, lo que hace que el espaciado de los orificios de clasificación sea más estandarizado.

- The screening part of the drum adopts silica gel to directly contact the raw materials without damaging them.

- Con alta precisión de clasificación, la máquina puede clasificar el ajo en tamaños estándar de 4,5 cm, 5,0 cm, 5,5 cm, 6,0 cm, 6,5 cm, y más 6,5 cm. También están disponibles tamaños personalizados bajo petición.

- La pantalla de clasificación está hecha de PVC malla, y la mesa de alimentación está equipada con cepillos para garantizar que el ajo no se dañe.

- La máquina clasificadora de ajo ofrece múltiples niveles de clasificación. Dependiendo de la escala de procesamiento, puedes elegir 2, 3, 4 o 5 clases, lo que mejora en gran medida la eficiencia del procesamiento primario del ajo.

El principio de funcionamiento de la clasificadora de ajo comercial.

The machine uses a lifting conveyor to feed garlic into the grading machine. The garlic moves along the conveyor into a grading drum with round holes of increasing sizes. During sorting, garlic falls gradually into the corresponding collection containers by size and then passes through the discharge outlet into packing bags, achieving automated grading and collection.

Structure of the garlic sorting machine

The garlic sorting machine mainly consists of a lifting system, a conveying system, a grading device, a collection system, and a control system.

Lifting system

Machine: Belt elevator

Function: Lifts garlic from the ground or feed inlet to the working height of the grading machine, ensuring continuous feeding

Conveying system

Machine: Chain conveyor

Function: Evenly transports garlic to the grading drum or grading wheel

Grading device

Machine: Round-hole drum sieve

Function: Holes increase in size from small to large, sorting garlic by size

Collection system

Machine: Hopper

Function: Collects garlic of different sizes separately

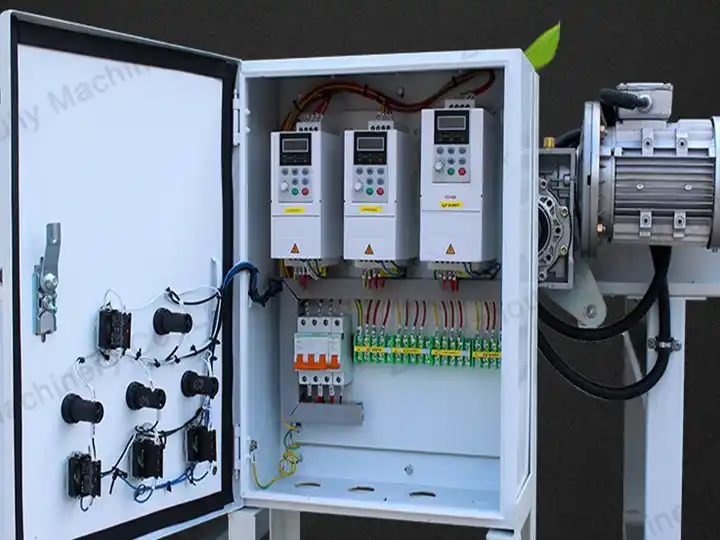

Control system

Machine: PLC intelligent control box

Function: Controls the entire machine operation, including motor start/stop and conveyor speed adjustment

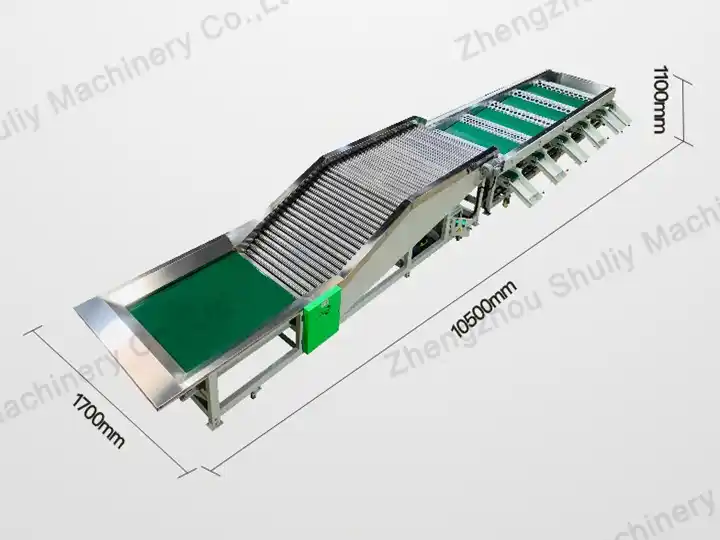

Parámetros de la máquina clasificadora de ajo comercial

| Modelo | SL-3 | SL-4 | SL-5 |

| Fuerza | 1,1 kw | 1,1 kw | 1,1 kw |

| Voltaje | 380V | 380V | 380V |

| Capacidad | 1-2t/h | 3-4t/h | 5-6t/h |

| Tamaño | 3505*955*925mm | 8000*1400*800mm | 10500*1700*1100mm |

If you have more requirements, we can customize the machine according to your needs, such as power voltage, plug type, sieve hole size, or more grading levels. You are welcome to contact us for consultation.

Garlic grading machine ROI analysis

After purchasing a garlic grading machine, it is important to consider its return on investment (ROI). The ROI can be evaluated from several aspects: cost input, increased output, labor savings, and added product value. Here, we assume a small to medium-sized garlic paste processing factory with a daily processing capacity of about 4 tons. The above prices are for reference only and do not reflect actual purchase costs.

| Item | Value |

|---|---|

| Equipment investment cost | $10,000 |

| Installation and commissioning | $1,000 |

| Daily processing capacity | 4 tons |

| Garlic price | $1,000/ton (raw material cost, not profit, used for output calculation) |

| Increased output efficiency | 5% |

| Labor savings | 2 people × $10/day × 25 days/month = $500/month |

| Operating cost | $100/day × 25 days/month = $2,500/month |

Revenue from increased output

- Original daily output value: 4 tons × $1,000 = $4,000

- Efficiency increase 5% → Additional output value: $4,000 × 5% = $200/day

- Monthly added value (25 days): $200 × 25 = $5,000

Labor savings

- Monthly labor cost savings: $500

Monthly net profit

- Monthly added value + labor savings – operating cost

- $5,000 + $500 – $2,500 = $3,000/month

Investment payback period

- Total investment: $10,000 + $1,000 = $11,000

- Monthly net profit: $3,000

- Payback period = $11,000 ÷ $3,000 ≈ 3.7 months

Conclusion

Under these assumptions, the garlic grading machine can pay back in about 4 months. After that, the increased output and labor savings almost entirely convert to profit, giving a very high return on investment.

Garlic deep processing

Shuliy has over ten years of production and sales experience and offers a full range of garlic processing machines, including garlic clove splitters, garlic peelers, garlic washers, and more. We can also provide complete solutions for garlic powder and garlic paste production lines. You are welcome to contact us through the pop-up chat for more information.

Producto caliente

Máquina de Plantación de Ajo

La máquina plantadora de ajo es una herramienta agrícola…

Máquina para Hacer Pasta de Jengibre y Ajo

La máquina automática para elaborar pasta de jengibre y ajo es ampliamente…

Máquina de envasado al vacío de dientes de ajo

Máquina de envasado al vacío de dientes de ajo con núcleo de cobre 20L…

Máquina de Clasificación de Ajo

La clasificadora comercial de ajos utiliza cilindros para clasificar…

Línea de producción de pelado de ajo | maquina procesadora de ajo

La línea de producción peladora de ajo es muy práctica…

Peladora de ajos

Una peladora de ajo está diseñada para pelar…

Máquina de secado al aire de ajo

La máquina de secado por aire para ajo es altamente…

Máquina Separadora de Dientes de Ajo

La máquina separadora de dientes de ajo está diseñada para separar eficientemente…

Línea de producción de ajo en polvo

La línea de producción de polvo de ajo incluye principalmente ajo…