The garlic powder grinding machine is a multifunctional grinder that can quickly grind dried garlic slices into garlic powder. It is widely used in the food, feed, chemical, pharmaceutical, and agricultural industries.

This industrial garlic powder grinder is made of food-grade stainless steel, which is corrosion-resistant, easy to clean, and ensures no contamination of garlic powder. With a high rotating speed, it can grind fine garlic powder of 60–120 mesh, with a capacity of 10–3000 kg/h.

It is mainly used for grinding dry materials such as spices, pepper, chili, ginger, garlic, coffee beans, cocoa beans, herbs, tea leaves, wheat, chemical raw materials, and dried fruits. High-oil materials such as sesame, walnut, peanut, almond, and melon seeds cannot be ground alone. For processing, they should be mixed with low-oil or oil-free materials, with the oil content kept below 25%. For large, high-oil materials, a crusher or stainless-steel coarse crusher should be used first, and then the material can be processed by the superfine grinding machine.

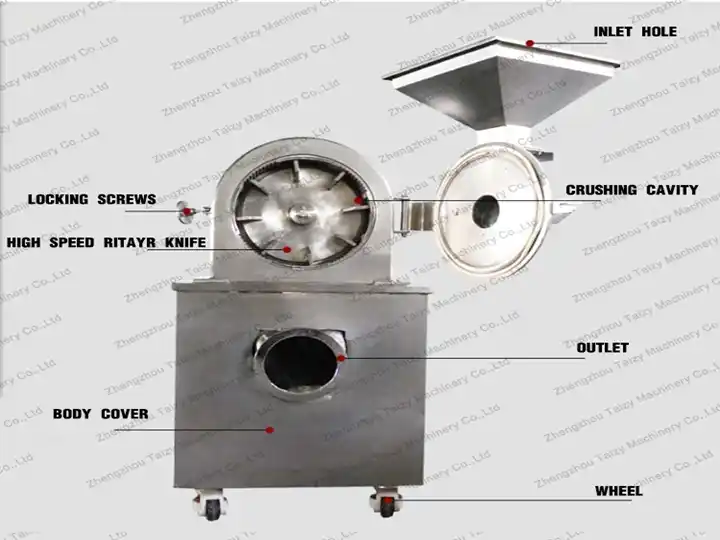

ガーリックパウダー粉砕機の構成要素

ガーリックパウダーミルは一般的にホッパー、高速回転刃、破砕室、ロックネジ、本体カバー、出口、車輪、手動およびインテリジェント制御ボタンで構成されます。

ホッパー: ニンニクスライスを粉砕室に保持し誘導します。

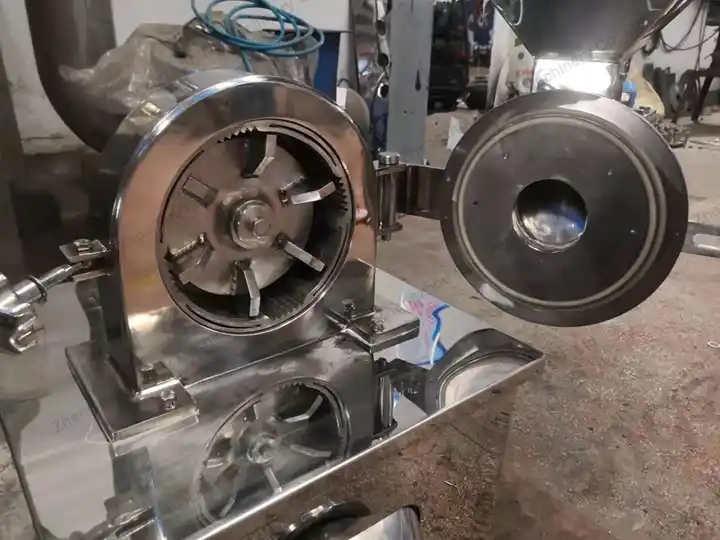

高速回転刃: ニンニクを切断、破砕、微粉化します。

破砕室: ニンニクが効率的に粉砕される空間を提供します。

ロックネジ: 部品を固定して安全な運転を確保します。

本体カバー: 内部部品を保護し、破片の飛散を防ぎます。

出口: 仕上がったガーリックパウダーを機械から排出します。

車輪: 粉砕機の移動と可搬性を容易にします。

手動およびインテリジェント制御ボタン: 操作モードの制御および開始/停止機能。

ガーリックパウダー製造機の動作原理

ガーリックパウダー粉砕機は、刃ディスクまたは歯ディスクの高速回転が固定部品に対して働き、衝撃、せん断、摩擦によって粉砕を実現します。原料はホッパーから粉砕室に入り、遠心力で自動的に排出されます。粒度は、異なる開口のふるいを交換することで調整できます。

本機は構造が簡単で、運転が安定し、騒音が低いです。ステンレス製で、GMP基準に適合し、清掃が容易で、ガーリックパウダーや類似原料の効率的な粉砕に最適です。

生姜ガーリックパウダー粉砕機の利点

複数モデル、広い処理能力の範囲

- 型番: SL-15B から SL-100B

- 処理能力: 10–3000 kg/h

- 用途: 食品加工工場、調味料工場、農産物の深加工企業

効率的な粉砕構造

- 垂直粉砕構造

- 高速回転刃/歯ディスクが固定ディスクに対して衝撃、せん断、粉砕を行います

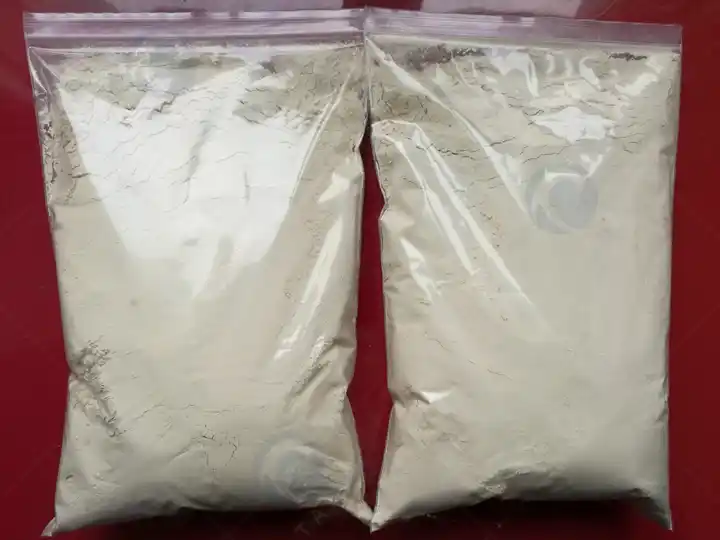

- 粒度: 60–120 メッシュ、ふるい交換で調整可能

高性能ドライブ

- 主軸回転数: 1500–6000 r/min

- モーター出力: 2.2–37 kW

- 安定した運転、低騒音、連続生産に適しています

食品グレードステンレス鋼 304

- 耐腐食性、錆なし

- GMP食品加工基準に適合

- ガーリックパウダーは自然な色と純粋な香りを保持します

操作とメンテナンスが簡単

- 便利な給餌、自動排出

- 分解と清掃が容易

- 原料の頻繁な切り替えがある生産に最適

コンパクトで柔軟

- 寸法: 550×400×850 mm から 1350×1000×2100 mm

- 重量: 150–1580 kg

- 処理能力や工場スペースに応じて柔軟に選択可能

ステンレス製ガーリックパウダー製造機のパラメーター

| タイプ | SL-15B | SL-20B | SL-30B | SL-40B | SL-50B | SL-60B | SL-80B | SL-100B |

| 生産能力(KG/H) | 10-50 | 60-150 | 100-300 | 160-800 | 300-1000 | 500-1500 | 600-2000 | 800-3000 |

| 投入サイズ(mm) | 6 | 6 | 10 | 12 | 15 | 15 | 15 | 15 |

| 破砕繊度(メッシュ) | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 |

| モーター出力 (KW) | 2.2 | 4 | 7.5 | 11 | 15 | 22 | 30 | 37 |

| 主軸回転数(R/Min) | 6000 | 4500 | 3800 | 3400 | 2900 | 2900 | 2000 | 1500 |

| 重量(KG) | 150 | 280 | 340 | 450 | 600 | 900 | 1250 | 1580 |

| サイズ (MM) | 550*400*850 | 600*550*1250 | 700*600*1450 | 900*800*1550 | 1050*850*1750 | 1100*900*1880 | 1200*950*2000 | 1350*1000*2100 |

乾燥したニンニクスライスを粉末にする方法?

- 給餌: 乾燥させたニンニクスライスを均等にホッパーに注ぎます。

- 粉砕: ニンニクスライスは粉砕室に入り、高速回転する刃によって衝撃、剪断され、粉末状に粉砕されます。

- ふるい分けと排出: 粉末ニンニクはふるいを通して等級分けされます。粒子サイズはふるいを変更することで調整可能で、通常の供給サイズは6〜15 mmです。

- 収集: 認定されたニンニク粉は排出口から排出され、容器または包装機に集められます。Shuliyは 半自動 サイズ:8*1.4*0.8m 完全自動ニンニク粉包装機。

内部構造表示

発送表示

粉砕効果表示

ガーリックパウダー生産ライン

The ニンニク粉生産ラインは新鮮なニンニクを乾燥ニンニク粉に加工します。主な工程は鱗片の分離、皮むき、スライス、洗浄、脱水、粉砕、包装です。工場で作られるニンニク粉は粒度が均一です。最終製品は輸送と保管が容易になるように包装されます.

人気商品

ニンニクの皮むき生産ライン |ニンニク加工機

にんにく皮むき生産ラインは非常に実用的です…

機械の能力に応じて袋と製品を積載し、過負荷をかけないでください。

このにんにくパウダー包装機は完全に…

オニオンリングカッティングマシン

玉ねぎリングカッティングマシン、または…

ダブルベルトニンニク根凹面切断機

ニンニクの凹根切断機は、ニンニクの根を除去します。

セミオートマチックにんにくパウダー包装機

半自動にんにく粉末包装機は…に使用されます

ニンニク空気乾燥機

にんにく空気乾燥機は高性能です…

ニンニク乾燥機 | 産業用ニンニク乾燥オーブン

ニンニク乾燥機はホットエア循環…

ニンニクの皮むき機

にんにく皮むき機は皮をむくために設計されています…

タマネギの根切り器

タマネギの根切り器は、別名タマネギ…