セミオートマチックなガーリックパウダー包装機は、ガーリックパウダーを包装容器に正確に充填するために使用される装置です。また、食品、化学、農業、その他の産業における粉末材料の包装にも適しています。

この機械はスクリュー充填方式を採用しており、正確な計量と簡単な操作を保証します。袋、ボトル、缶など、さまざまな形態で充填できます。

この機械は操作が簡単で、精度が高く、適応性に優れています。充填精度は±1%以内に制御され、充填速度は500〜1500袋/時です。充填重量は1〜10キログラムの間で調整可能です。

この機械は、給餌機や封入機と連携して動作することもでき、ニンニク粉末生産ラインにおいて重要な役割を果たします。

半自動ニンニク粉末包装機の利点

- 自動メータリングシステム: 機械、電気、光学、計測技術を統合し、マイクロコントローラーによって制御され、自動的に計量、充填、エラー修正を完了します。

- 高速包装速度:スクリュー給餌システムと光電制御を使用して、迅速な応答と高効率を実現します。

- 高測定精度: 高性能の電子スケールとステッピングモーターを搭載し、精密な制御を行います。

- 衛生的で安全: 食品グレードのステンレス鋼(SUS304)で完全に製造されており、清掃が容易で、交差汚染を効果的に防ぎます。

- 広範な包装範囲キーボードから1kgから10kgまで調整可能で、スクリューを変更することで異なるサイズに適応します。

- 幅広い素材互換性: ニンニク粉末の他に、さまざまな自由流動性の粉末材料にも適しています。

- インテリジェントエラー修正: 材料の密度変化や材料レベルの変動によって引き起こされるエラーを自動的に追跡し、修正します。

- 簡単操作: 手動で袋を配置するだけで、光電センサーが自動給餌を制御し、袋の開口部を整然と保ち、封入の準備をします。

手動にんにく粉包装機の構成と動作原理

ストレージホッパー

にんにく粉を保存し、連続的な供給を確保します。ステンレス鋼製で、掃除が簡単で、付着を防ぎます。

スクリュー供給システム

設定された量に応じてホッパーから出口へ粉を押し出し、モーター制御により正確な供給を実現します。

重量センサーと制御システム

電子スケールを使用して各フィードの重量をリアルタイムで監視し、自動計量とエラー修正のためにPLC制御システムに接続されています。

最終編集: 2025/6/20

包装サイズ、速度、誤差範囲などを設定できます。ディスプレイとボタンがあり、一部のモデルにはタッチスクリーンインターフェースが含まれています。

排出口と充填ノズル

計量後、粉はここで手動で置かれた容器に排出されます。ノズルは取り外し可能で、異なるサイズに簡単に交換できます。

フレームとケース

機械のフレームは高品質のステンレス鋼製で、頑丈で耐久性があり、食品衛生基準を満たしています。

適切な材料と適用シナリオ

材料

| 業界カテゴリ | 一般的な材料 |

| 食品業界 | 粉ミルク、デンプン、調味料粉, および酵素製剤 |

| 農業産業 | 飼料、プレミックス、獣医薬品、 農薬粉 |

| 化学産業 | 添加物、洗剤粉、 化学粉末 |

適用シナリオ

- 食品加工工場

- 農産物生産ライン

- 飼料または添加物の包装ステーション

- 化学製品包装作業場

- スパイスおよび調味料製造工場

- Eコマース梱包作業

半自動にんにく粉包装機の技術的パラメータ

| パラメータ | 仕様 |

| 電源供給 | AC 380V, 900W |

| 充填範囲:80g以内 | 1–10 kg |

| 包装精度 | ±1% |

| にんにく粉包装機 | 自動にんにく粉包装機 | 500–1500 袋/時 |

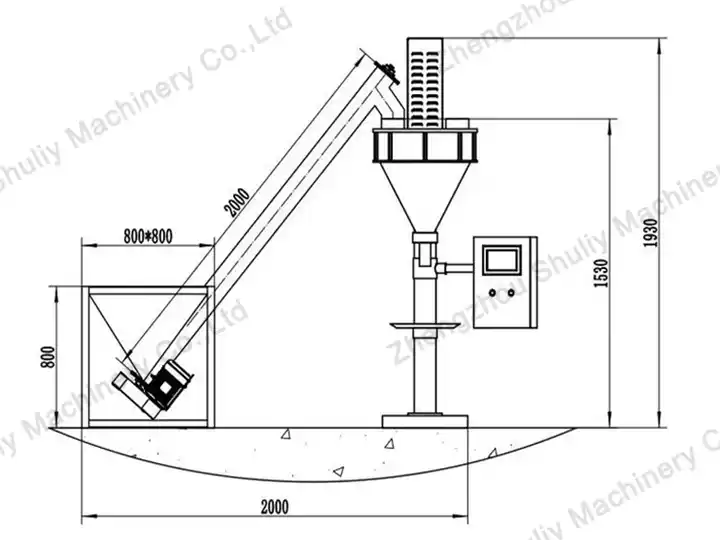

| 機械寸法 | 1000 × 850 × 1850 mm |

| 機械の重量 | 280 kg |

カスタマイズサービスも提供しており、お客様の要件に応じて機械を変更できます。

半自動ニンニク粉包装機の使い方は?

- 接続電源: 電圧がAC380Vであることを確認し、接地が正しく接続されているか確認してください。

- 材料を追加: 粉材料(ニンニク粉、ミルク粉など)を供給機またはホッパーに注ぎます。

- チェック: ホッパーとスクリューが清潔で、ゴミや残留粉がないことを確認してください。

- パラメータを設定: 包装重量を設定(例:1kg、2kgなど)/包装速度を調整/許容誤差範囲を設定(±1%)

操作プロセス:手動で袋またはボトルを配置 → 充填開始 → 自動計量と充填 → 充填後に停止 → 充填済み袋またはボトルを取り外します。

どの機械を一緒に使用できますか?

フィーディングマシン

| パラメータ | 仕様 |

| リフティング能力 | 1000–3000 kg/h |

| ホッパー容量 | 100–300 kg |

| 給餌高さ | 2000 mm(カスタマイズ可能) |

| 電源供給 | AC 380V, 1100W |

| 材料 | ステンレス鋼 |

| 機械の重量 | 150 kg |

連続封止機

| パラメータ | 仕様 |

| 電源供給 | 220V 50Hz 520W |

| 封止幅 | 調整可能 5–14 mm |

| シーリング材料の厚さ | 0.03~0.80 mm |

| シーリング能力 | 最大55袋/分(100 mm袋に基づく) |

| シーリング速度 | 0〜12 m/min |

| 温度範囲 | 0〜300°C |

| 機械寸法 | 810 × 370 × 310 mm |

| 最大印刷文字数 | 39文字以下 |

| 重さ | 17.5 kg |

にんにく粉生産ラインでの応用

ガーリックパウダー生産ラインでは、包装機は通常、最終工程である包装に使用されます。

ニンニク粉包装機のメンテナンスとケア

- 毎日の作業後にホッパーと供給パイプを清掃してください。

- スクリューコンベヤーを毎週点検し、摩耗や詰まりがないか確認してください。

- 電気制御システムと配線を毎月点検し、老朽化や緩みがないか確認してください。

- ベアリング部品に潤滑油を塗布して(該当する場合)、機械の寿命を延ばしてください。

私たちと協力してください

ご興味のある方は、WhatsAppで直接詳細をお問い合わせください:https://wa.me/+8619139761487

人気商品

にんにく房分離機

ニンニク分離機は、効率的に分離するように設計されています…

にんにくクローブ真空包装機

20L銅芯付きにんにくクローブ真空包装機…

ニンニク乾燥機 | ニンニクベルト乾燥機

ニンニク脱水機は一般に…

ニンニクスライサー機

にんにくスライサーは高性能で多機能、操作が簡単で…

ニンニク植え付け機

にんにく植え付け機は農業用具です…

ニンニクの皮むき生産ライン |ニンニク加工機

にんにく皮むき生産ラインは非常に実用的です…

ダブルベルトニンニク根凹面切断機

ニンニクの凹根切断機は、ニンニクの根を除去します。

ニンニクの皮むき機

にんにく皮むき機は皮をむくために設計されています…

ニンニクスライサー機

このガーリックスライサーマシンは操作が簡単です…