ガーリックエアドライヤー

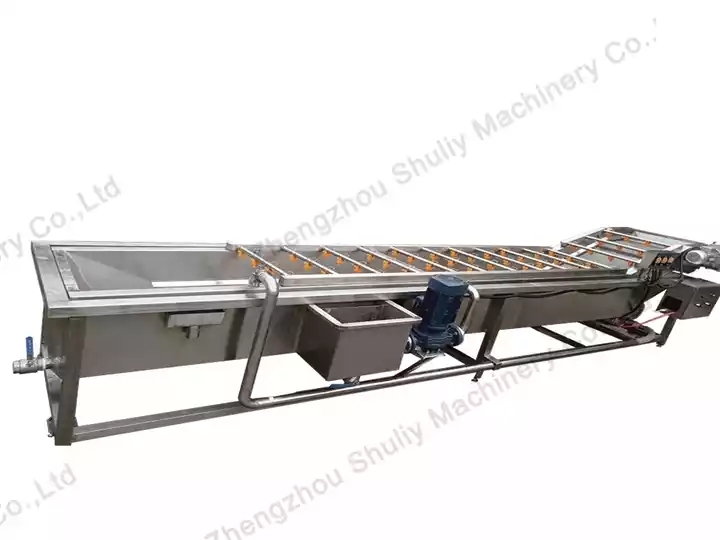

ニンニク洗浄機は、ブロワーを使用して洗浄槽に空気を注入し、水流を発生させてニンニクの表面を洗浄し、汚れを効果的に除去します。

10アイテム

SL-800ニンニク洗浄機の動作原理は何ですか?

ニンニク洗浄機のサイズは2000*1380*1200mm、総電力は0.55kW、機械には車輪が装備されており、帯域幅は800mm、使用電圧は380V、50Hzです。

ShuliyブランドSL-800ニンニク洗浄機は、食品グレードのステンレス鋼304ステンレス鋼板、メッシュベルト搬送システム、エアポンプ配管システム、ポンプ配管システムで構成されています。3つの主要システムはそれぞれ独立して切り替え可能で、相互に干渉することなく個別に動作できます。

ニンニクパウダー包装機 | 自動ニンニクパウダー包装機

ガーリックエアドライヤー

エアポンプ:ブロワーを介して洗浄槽の底にあるバブルパイプまたはバブルストーンに空気を送り込み、多数の高密度気泡を生成します。

ガーリックパウダー包装機 | 自動ガーリックパウダー包装機

ウォーターポンプ:ウォーターポンプは、ろ過された水をタンクから汲み上げることができます。

メルトベルト:気泡の衝撃や上端での水のろ過に適しており、底には穴のあるガスパイプがあり、ガスが上向きに衝撃を与え、水流と接触して気泡を形成するのに便利です。

バブルアッパー高圧ノズル:ウォーターポンプによって汲み上げられた水は、配管を通してバブルアッパーノズルに輸送されます。

電子制御ボックス:モーター、ポンプ、エアポンプのすべての制御スイッチ、および搬送速度、気泡強度、スプレー圧力などのパラメータ調整ボタンまたはタッチスクリーンを統合しています。機械の安定した操作と運用上の安全性を確保します。

フィルタータンク:洗浄槽から水を汲み出し、ろ過システム(ヘアフィルター、ふるいなど)を介して大きな不純物や浮遊物を除去した後、洗浄槽に戻して水を汲み上げ、水資源のリサイクルを実現し、水を節約し、洗浄水の相対的な清潔さを維持します。

ガーリックエアドライヤー

モデル:TZ-4000

サイズ:4000*1200*1300mm

重量:400kg

電力:4.1kw

容量:800kg/時

モデル:TZ-5000

サイズ:5000*1200*1300mm

重量:500kg

電力:5.1kw

容量:1500kg/時

ガーリックパウダー包装機 | 自動ガーリックパウダー包装機