Garlic Powder Grinding Machine

The garlic powder grinding machine is a multifunctional grinder that can quickly grind dried garlic slices into garlic powder. It is widely used in the food, feed, chemical, pharmaceutical, and agricultural industries.

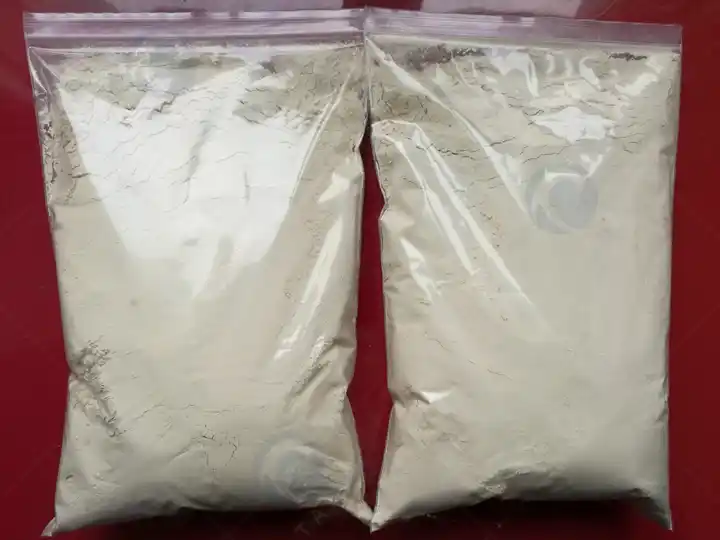

This industrial garlic powder grinder is made of food-grade stainless steel, which is corrosion-resistant, easy to clean, and ensures no contamination of garlic powder. With a high rotating speed, it can grind fine garlic powder of 60–120 mesh, with a capacity of 10–3000 kg/h.

It is mainly used for grinding dry materials such as spices, pepper, chili, ginger, garlic, coffee beans, cocoa beans, herbs, tea leaves, wheat, chemical raw materials, and dried fruits. High-oil materials such as sesame, walnut, peanut, almond, and melon seeds cannot be ground alone. For processing, they should be mixed with low-oil or oil-free materials, with the oil content kept below 25%. For large, high-oil materials, a crusher or stainless-steel coarse crusher should be used first, and then the material can be processed by the superfine grinding machine.

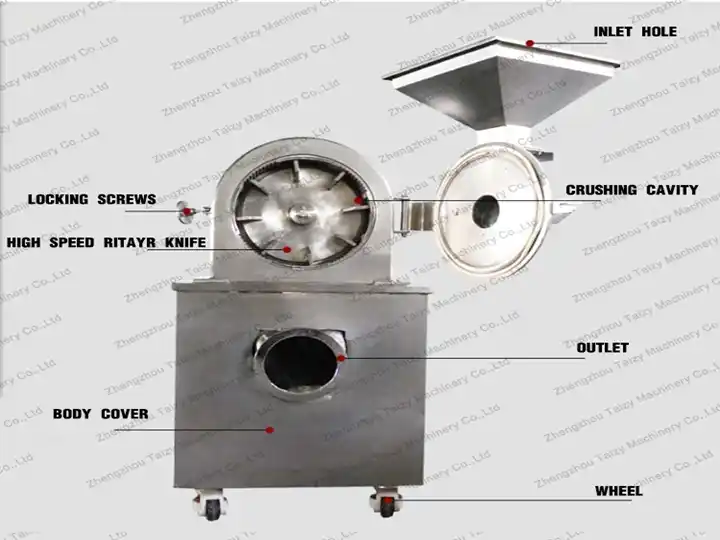

Garlic powder grinder machine components

A garlic powder grinder generally consists of a hopper, a high-speed rotating blade, a crushing cavity, locking screws, a body cover, an outlet, wheels, and manual and intelligent control buttons.

Hopper: Holds and guides garlic slices into the grinding chamber.

High-speed rotating blade: Cuts, crushes, and pulverizes garlic into fine powder.

Crushing cavity: Provides the space where garlic is ground efficiently.

Locking screws: Secure parts in place to ensure safe operation.

Body cover: Protects internal components and prevents debris from escaping.

Outlet: Allows the finished garlic powder to exit the machine.

Wheels: Enable easy movement and portability of the grinder.

Manual and intelligent control buttons: Control operation modes and start/stop functions.

Working principle of the garlic powder making machine

The garlic powder grinding machine works through the high-speed rotation of a blade disc or tooth disc against fixed components, achieving crushing by impact, shear, and friction. The material enters the grinding chamber through the hopper and is discharged automatically under centrifugal force. The particle size can be adjusted by changing sieves with different apertures.

The machine features a simple structure, stable operation, and low noise. Made of stainless steel, it meets GMP standards, is easy to clean, and is ideal for efficient grinding of garlic powder and similar materials.

Advantages of the ginger garlic powder grinding machine

Multiple models, wide capacity range

- Models: SL-15B to SL-100B

- Capacity: 10–3000 kg/h

- Applications: Food processing factories, seasoning factories, agricultural product deep-processing enterprises

Efficient grinding structure

- Vertical grinding structure

- High-speed rotating blade/teeth discs impact, shear, and grind against fixed discs

- Particle size: 60–120 mesh, adjustable by changing sieves

High-performance drive

- Spindle speed: 1500–6000 r/min

- Motor power: 2.2–37 kW

- Stable operation, low noise, suitable for continuous production

Food-grade stainless steel 304

- Corrosion-resistant, rust-free

- Meets GMP food processing standards

- Garlic powder retains natural color and pure aroma

Easy operation & maintenance

- Convenient feeding, automatic discharge

- Easy to disassemble and clean

- Ideal for production with frequent material changes

Compact and flexible

- Dimensions: 550×400×850 mm to 1350×1000×2100 mm

- Weight: 150–1580 kg

- Can be selected flexibly according to capacity and workshop space

Parameters of stainless steel garlic powder making machine

| Type | SL-15B | SL-20B | SL-30B | SL-40B | SL-50B | SL-60B | SL-80B | SL-100B |

| Production capacity (KG/H) | 10-50 | 60-150 | 100-300 | 160-800 | 300-1000 | 500-1500 | 600-2000 | 800-3000 |

| Feeding size(mm) | 6 | 6 | 10 | 12 | 15 | 15 | 15 | 15 |

| Crushing fineness (Mesh) | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 |

| Motor Power (KW) | 2.2 | 4 | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Spindle speed (R/Min) | 6000 | 4500 | 3800 | 3400 | 2900 | 2900 | 2000 | 1500 |

| Weight (KG) | 150 | 280 | 340 | 450 | 600 | 900 | 1250 | 1580 |

| Size (MM) | 550*400*850 | 600*550*1250 | 700*600*1450 | 900*800*1550 | 1050*850*1750 | 1100*900*1880 | 1200*950*2000 | 1350*1000*2100 |

How to grind dried garlic slices into powder?

- Feeding: Pour the dried garlic slices evenly into the hopper.

- Grinding: The garlic slices enter the grinding chamber, where high-speed rotating blades impact, shear, and crush them into powder.

- Sieving & discharge: The powdered garlic passes through a sieve for grading. Particle size can be adjusted by changing the sieve, typically with a feed size of 6–15 mm.

- Collection: The qualified garlic powder is discharged from the outlet and collected into a container or packaging machine. Shuliy provides semi-automatic and fully automatic garlic powder packaging machines.

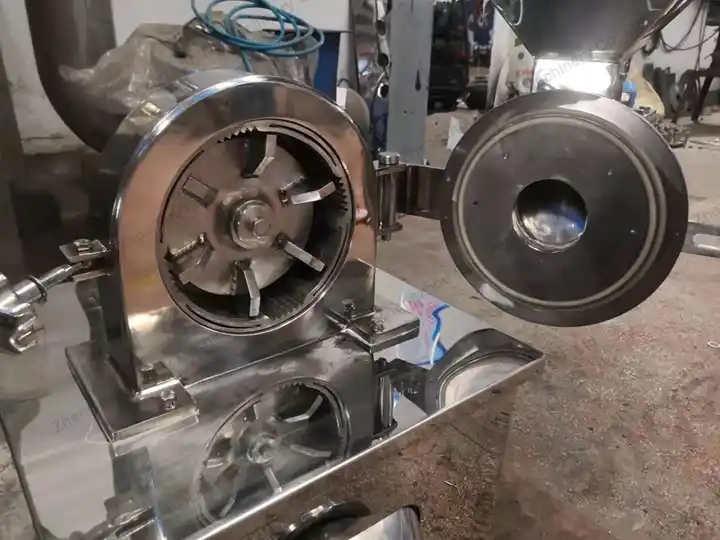

Internal structure display

Shipping display

Grinding effect display

Garlic powder production line

The garlic powder production line processes fresh garlic into dry garlic powder. The main steps include clove separating, peeling, slicing, washing, dehydrating, grinding, and packaging. The garlic powder made in the factory has a uniform fineness. The final product is packed for easy transport and storage.

Hot Product

Garlic powder production line

The garlic powder production line mainly includes garlic…

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Chain-type Peeling Machine | Commercial Garlic Peeler

The chain-type garlic peeling machine is specially designed…

Garlic Planting Machine

The garlic planting machine is an agricultural tool…

Garlic Powder Packing Machine | Automatic Garlic Powder Packing Machine

This garlic powder packing machine is a fully…

Garlic Powder Grinding Machine

The garlic powder grinding machine applies for grinding…

Garlic Peeling Machine

A garlic peeling machine is desinged to peel…

Garlic Cleaning Machine

A fully automatic high-yield multifunctional garlic washing machine,…

Garlic Drying Machine | Garlic Belt Dryer

Garlic dehydrator machine is commonly known as a…