Ginger Garlic Paste Making Machine

The garlic paste making machine uses multiple blade sets for rapid cutting and crushing, turning garlic into a smooth paste or juice.

Made of food-grade 304 stainless steel, the machine is rust-resistant, wear-resistant, and durable, meeting food hygiene standards.

This machine has a capacity of 300–500 kg/h, is easy to operate, and has a service life of up to 10 years.

This machine is not only suitable for garlic but also for ginger, onions, and other vegetables, producing a fine puree. It is widely used in restaurants, hotels, canteens, food processing factories, and vegetable processing industries.

Advantages of the garlic paste making machine

Capacity:300–500 kg/h

Material: food-grade 304 stainless steel, easy to clean, corrosion-resistant, and durable

Versatile: Can process garlic, ginger, tomatoes, potatoes, and other vegetables with excellent results.

Customizable: The texture of the paste can be adjusted according to customer needs, and it can also process other vegetables and fruits, offering high flexibility.

Labor-Saving: Automated operation replaces traditional manual garlic mincing.

Durable and Stable: The machine has a robust structure, suitable for long-term continuous use.

Safe and Reliable: Equipped with protective devices and an emergency stop switch for safe operation.

Blade material: Made of AISI 304 stainless steel, the blades are rust- and corrosion-resistant, durable, and come with free replacement blades.

Working principle of the garlic grinder

The garlic grinder uses high-speed stainless steel blades driven by a motor to crush and grind garlic cloves into a smooth paste. Garlic is fed into the machine, cut and pulverized rapidly, and then discharged as uniform garlic paste or juice, ready for cooking or further processing.

Working process of the garlic paste making machine

Prepare ingredients

Select fresh garlic, peel and clean it. A garlic peeling machine can be used for efficiency.

Feeding

Place the peeled garlic into the feeding inlet of the garlic grinder.

Chopping and grinding

High-speed rotating blades inside the machine chop and grind the garlic into a uniform paste.

Discharge and collection

The garlic paste is discharged from the outlet and collected in a container.

Cleaning and maintenance

Clean the machine promptly after use to maintain hygiene and extend its service life.

Parameters of the garlic paste making machine

Model: SLRYS-300

Voltage: 220-380V

Power: 3KW

Size:70*50*100CM

Capacity: 300-500KG/H

Production date: 10~15 working days

Transportation: By sea or by air

These are our standard models. The power voltage and plug can be customized according to your needs. You are welcome to contact us through the pop-up for inquiries.

Application of the ginger garlic paste machinery

This ginger garlic paste machinery can cut vegetables and fruits into a very thin pulp. It is suitable for the processing of garlic, ginger, chili sauce, tomato sauce, jam, and other foods.

The thickness of the vegetable puree can be adjusted according to the needs of the product, which is suitable for the deep processing of fruits and vegetables. This garlic paste equipment can be widely used in food processing enterprises such as chili sauce factories.

Garlic paste machine maintenance guide

Daily maintenance

- Cleaning: After each use, immediately clean the blades, grinding wheels, discharge outlet, and all parts that contact the garlic paste to prevent residue from rotting.

- Drying: Wipe or air-dry the cleaned parts to avoid rust.

- Check Fasteners: Regularly inspect screws and nuts; tighten if necessary.

Periodic maintenance

- Lubrication: Apply lubricating oil to moving parts (like bearings and rollers) regularly.

- Blade Care: If blades are worn, sharpen or replace them to maintain effective chopping.

- Motor Check: Regularly check if the motor runs normally, without unusual noise or overheating.

Precautions

- Never touch the rotating blades with your hands.

- Do not overload the machine to avoid motor damage.

- If not used for a long time, clean thoroughly, cover to prevent dust, and store in a dry, ventilated place.

Deep processing of garlic

In addition to garlic paste machines, we also offer garlic clove splitters, garlic peelers, garlic washing machines, garlic air-dryers, and more. We can provide a complete garlic paste processing production line.

Complete production process and considerations for garlic paste

Why choose Shuliy garlic paste machines?

- High efficiency and reliability: Stable performance with high production efficiency.

- Easy operation: User-friendly design, reducing training costs.

- Simple maintenance: Well-designed for easy cleaning and upkeep.

- Hygienic and safe: Stainless steel construction with uniform grinding, ensuring quality garlic paste.

- Complete solutions: Provide full-process garlic paste production line equipment to improve workflow efficiency.

Hot Product

Garlic Slicer Machine

Garlic slicer high performance, multi-functional, easy control of…

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Garlic Clove Vacuum Packing Machine

Garlic clove vacuum packing machine with 20L copper-core…

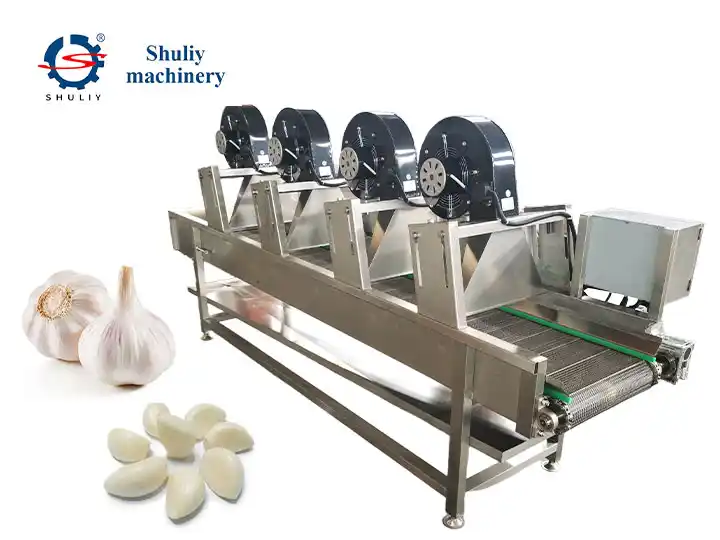

Garlic Air Drying Machine

The garlic air drying machine is a highly…

Semi-Automatic Garlic Powder Packing Machine

The semi-automatic garlic powder packing machine is used…

Garlic Clove Separating Machine

Garlic clove separating machine is designed to efficiently separate…

Garlic Grading Machine

Commercial garlic grading machine use cylinders to classify…

Garlic Drying Machine | Garlic Belt Dryer

Garlic dehydrator machine is commonly known as a…

Manual Garlic Harvesting Machine

Garlic harvesting machine helps farmers to harvest garlic…