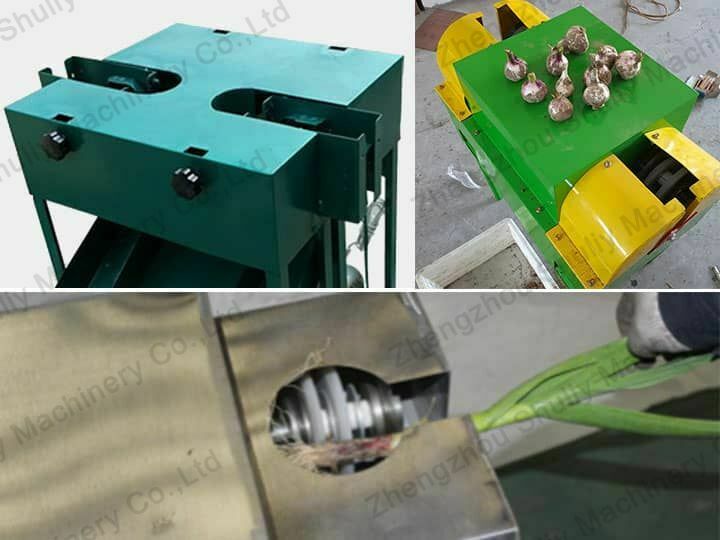

Garlic Root Stem Cutting Machine

The garlic root stem cutting machine is used to trim the necks of fresh garlic, producing whole and neat garlic bulbs. This machine uses manual feeding, which improves workers’ efficiency. This semi-automatic method is popular among many individual garlic growers and is one of Shuliy’s best-selling products.

This small machine can process 4,000–6,000 garlic bulbs per hour. Made of full stainless steel SUS304, it has a service life of over one year. Equipped with a 0.5 kW high-efficiency motor, it significantly reduces electricity costs. It also supports bulk orders and can be customized in color and appearance.

This garlic stem cutting machine is compact and space-saving, very easy to operate, and relatively affordable. It is suitable for small garlic processing factories and individual growers. If you want to learn more, you can contact me through the pop-up window.

Garlic root cutting machine working principle

The garlic root cutting machine requires manually placing garlic sprouts into the U-shaped slot. Rotating blade disc separate the garlic roots and stems from the bulbs, greatly improving processing efficiency and allowing easy control of the remaining stem length on the bulbs.

Garlic stem cutter specification

| Model | TZQ-02 |

| Voltage | 220v |

| Power | 0.5kw |

| Capacity | 4000~6000pcs/hour |

| Size | 0.59*0.66*1.115m |

| Weight | 50kg |

The whole machine is simple in structure and small in size, and can be moved to the field for work at any time. The garlic root cutting machine can process 4000~6000 heads of garlic per hour. We support any customization of the machine, including voltage, plug type, material, color, and more.You are welcome to contact us for inquiries.

Features and advantages of TZQ-02 garlic root cutting machine

High efficiency & labor-saving

The TZQ-02 can process 4,000–6,000 garlic bulbs per hour, greatly improving stem removal efficiency. Compared to manual work, it is faster, more stable, and can operate continuously, reducing labor costs and increasing output.

Low power, energy-saving and eco-friendly

The machine runs efficiently with only 0.5 kW of power. Compared with traditional large machines, it consumes less energy, making it suitable for small to medium factories and home workshops. Long working hours do not cause overheating, saving energy costs.

Compact design & small footprint

With dimensions of 0.59 × 0.66 × 1.115 m, it occupies minimal space and can be easily placed in workshops or home processing areas.

Lightweight, easy to move and simple operation

Weighing only 50 kg, it is easy to transport and move. The machine is well-structured with a simple interface, allowing even unskilled operators to quickly start and complete garlic stem removal.

Improves garlic quality

The precise cutting design effectively removes roots and stems while keeping bulbs intact and neatly shaped. This is important for high-end markets and export garlic, increasing product value.

Safe and reliable

Made of food-grade stainless steel, it is corrosion-resistant and easy to clean, ensuring hygiene during processing. The machine also has safety protections, making the operation secure and reliable.

Structure of the best-selling garlic root stem cutting machine

Frame and housing

Supports the machine, protects internal parts, corrosion-resistant and easy to clean.

Feeding inlet and conveyor

Manual feeding and smooth transport of garlic bulbs to the cutting area.

Stem-cutting device

High-speed rotating blade disc and fixed blades precisely remove roots and stems.

Separation and discharge system

Automatically separates clean garlic bulbs from root and stem residues and discharges them.

Power system

0.5 kW motor provides power for cutting and conveying.

Control system and safety devices

Simple switch operation, blades are protected to ensure safe operation.

Working Process of the garlic stem cutting machine

- Feeding: Operators place garlic bulbs into the feeding inlet one by one, ensuring even feeding for smooth stem cutting.

- Conveying: Garlic bulbs are guided smoothly to the cutting area via the conveyor, preventing damage or blockage.

- Stem cutting: High-speed rotating blade disc and fixed blades precisely remove roots and stems while keeping the bulbs intact.

- Separation: Cut roots and stems are automatically separated from the clean bulbs, improving efficiency and reducing manual sorting.

- Discharge: Neat garlic bulbs are collected from the discharge outlet, while root and stem residues are expelled. The bulbs can go directly to the next processing step or packaging.

- Control and safety: Simple operation with start/stop switches; protective covers ensure safe operation.

Applicable Scenarios

- Small to medium garlic processing factories: Quickly complete stem removal, improving production efficiency.

- Farmers or cooperatives: Suitable for small-scale processing, easy and convenient to operate.

- Pre-export processing: Ensures a neat garlic appearance, enhancing market competitiveness.

- Food processing factories: Provide pre-processing for garlic powder and garlic slice

Export case

The TZQ-02 garlic stem cutting machine has been successfully exported to an individual garlic grower in Egypt. Processing 4,000–6,000 bulbs per hour, it greatly improved the customer’s work efficiency. The machine cuts stems precisely while keeping bulbs intact, significantly enhancing product quality. It is easy to operate, occupies little space, and the customer reported stable performance, making it a perfect fit for their needs.

Garlic processing machine manufacturer

In addition to the garlic root cutting machine, we also offer garlic clove separators, garlic peelers, garlic slicers, garlic dryers, and more. We look forward to cooperating with you.

Hot Product

Garlic peeling production line | Garlic processing machine

The garlic peeling production line is very practical…

Garlic Cleaning Machine

A fully automatic high-yield multifunctional garlic washing machine,…

Garlic Powder Packing Machine | Automatic Garlic Powder Packing Machine

This garlic powder packing machine is a fully…

Garlic Drying Machine | Garlic Belt Dryer

Garlic dehydrator machine is commonly known as a…

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Garlic Grading Machine

Commercial garlic grading machine use cylinders to classify…

Garlic Air Drying Machine

The garlic air drying machine is a highly…

Garlic powder production line

The garlic powder production line mainly includes garlic…

Garlic Clove Vacuum Packing Machine

Garlic clove vacuum packing machine with 20L copper-core…