Garlic Clove Vacuum Packing Machine

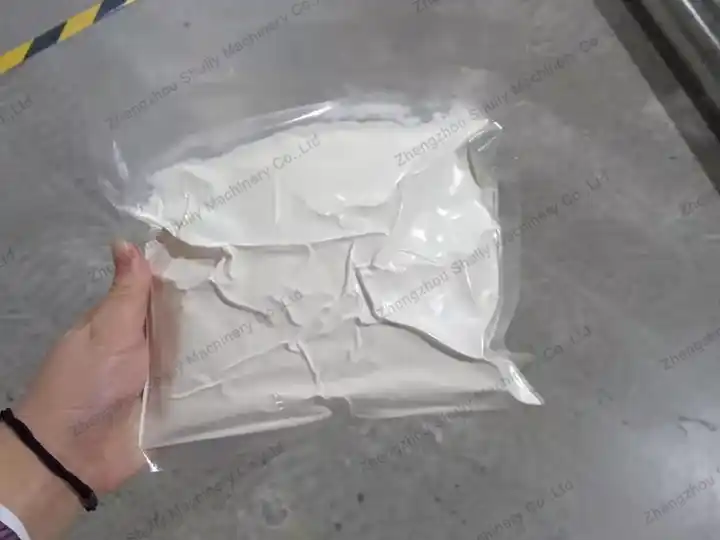

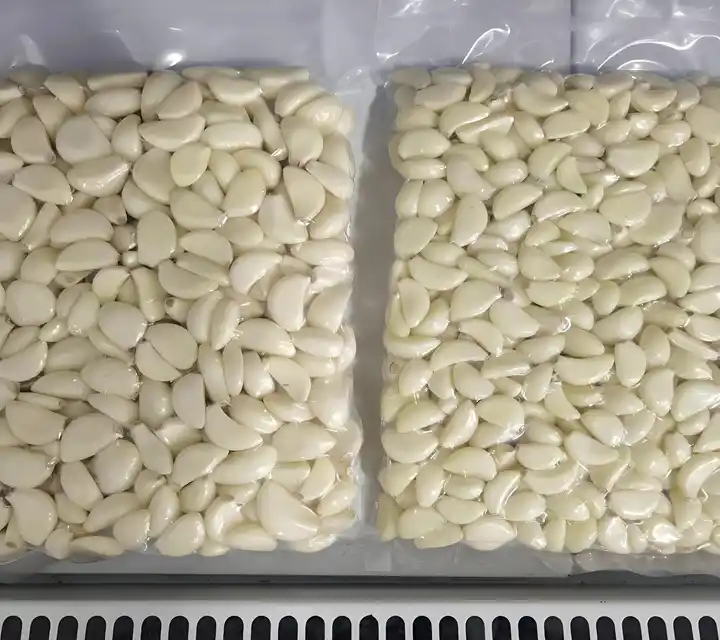

A garlic clove vacuum packing machine is used to vacuum seal peeled garlic cloves. The main purpose is to keep the garlic fresh for longer, stay clean and hygienic, and prevent spoilage and bad smell.

There are two main types of machines based on structure and efficiency: single-chamber and double-chamber vacuum packing machines.

The commercial multi-purpose garlic vacuum pack machine can not only pack garlic cloves, but also meat, dried food, vegetables, fruits, electronic parts, hardware, textiles, and more. It helps prevent oxidation, mold, moisture, and spoilage, keeping products fresh and in good condition.

The machine body is made of food-grade 304 stainless steel, which is smooth, corrosion-resistant, and easy to clean. It uses a 20L vacuum pump with a copper core to make sure the bag is fully sealed without air leaks.

Applications of the garlic clove vacuum packing machine

The garlic clove vacuum packing machine is widely used in many industries and situations. It is especially suitable for customers who need high standards in food hygiene, safety, and freshness. For example:

Peeled garlic processing plants

Fresh food distribution centers

Cold chain logistics

Supermarkets and food retailers

Agricultural product exporters

Garlic deep-processing food factories

Whether you are involved in primary garlic processing, fresh delivery, or export trade, this machine is an excellent choice to enhance product value and ensure quality.

Shuliy offers a range of models and custom options to meet diverse production and packaging requirements. Feel free to contact us for more details.

Types of garlic clove vacuum pack machines

- Single-chamber garlic vacuum clove packing machine

- Double-chamber garlic vacuum clove packing machine

Small single-chamber garlic clove vacuum packing machine for sale

Working principle

The single-chamber garlic clove vacuum packer machine works by removing air from the packaging bag and sealing it, which helps extend the garlic’s shelf life, prevents mold, and stops bad odors.

It has only one chamber, so compared to a double-chamber machine, it is smaller in size. You need to wait for one sealing cycle to finish before starting the next.

Product features

- Compact design, small footprint – ideal for small or medium-sized production spaces

- Easy to operate – only one person needed to run the full packing process

- Stable packing efficiency – can seal 1–2 bags at a time

- Suitable for low daily output or customized packing needs

- High vacuum level and strong sealing – helps garlic stay fresh longer

Technical parameters

| Model | Power | Material | Pump | Lid material | Weight | Size(cm) | CBM |

| SL-400A | 0.9kw | SS304 | 20L | Acrylic | 60Kg | 60*55*96 | 0.33 |

| SL-400/2H | 0.9kw | SS304 | 20L | Acrylic | 65Kg | 60*55*50 | 0.34 |

| SL-400/2S | 0.9kw | SS304 | 20L | Acrylic | 80Kg | 65*60*100 | 0.39 |

| SL-500/2H | 0.9kw | SS304 | 20L | Acrylic | 80kg | 75*65*102 | 0.5 |

| SL-600/2H | 1.5kw | SS304 | 20L/20*2 | Acrylic | 85Kg/100Kg | 85*75*102 | 0.65 |

Best-selling double-chamber garlic clove vacuum packer machine

Working principle

The double-chamber garlic clove vacuum packer machine features a two-chamber design that allows alternating operation. While one chamber is vacuuming and sealing, the other chamber can be loaded with products. This greatly reduces waiting time and improves overall efficiency.

Product features

- Two vacuum chambers work alternately for a higher packing speed

- High level of automation, supports continuous operation, and saves labor cost

- Ideal for medium to large factories and export-oriented businesses

- Can be connected to a full garlic processing line – from washing, peeling, to packing

- Strong machine stability, suitable for long-term, heavy-duty use

Technical parameters

| Model | Power | Material | Pump | Lid | Weight | Size(cm) | CBM |

| SL-400/2SD | 0.9kw | SS304 | 20L | SS304 | 120Kg | 120*68*100 | 0.85 |

| SL-500/2SD | 0.9kw | SS304 | 20L | SS304 | 130Kg | 130*78*100 | 1.2 |

| SL-500/2SD | 1.5kw | SS304 | 20L | SS304 | 150Kg | 130*78*100 | 1.2 |

| SL-600/2SD | 2.25kw | SS304 | 20L*2 | SS304 | 180Kg | 150*78*100 | 1.4 |

| SL-600/2SD | 2.25kw | SS304 | 20L*3 | SS304 | 220Kg | 150*78*100 | 1.4 |

| SL-700/2SD | 2.25kw | SS304 | 20L*3 | SS304 | 300Kg | 164.5*70.5*100 | 1.7 |

| SL-700/2SD | 2.5kw | SS304 | 63L | SS304 | 350Kg | 164.5*70.5*100 | 1.7 |

| SL-800/2SD | 3kw | SS304 | 100L | SS304 | 400Kg | 194*92*100 | 1.9 |

Why vacuum pack garlic cloves?

Vacuum packaging is a widely used method in modern food preservation. For garlic cloves, vacuum packing not only extends shelf life but also increases product value and makes transport easier. Key benefits include:

- Longer shelf life: Removes oxygen to slow bacterial and mold growth, preventing spoilage.

- Odor control: Garlic has a strong smell — vacuum sealing helps contain the odor.

- Clean and hygienic: The sealed bag keeps out dust, moisture, and contamination.

- Higher product value: Neat, uniform packaging improves appearance and brand image, making it more attractive to customers.

- Easier for transport and export: Vacuum-packed garlic takes up less space and is less likely to get damaged during shipping.

How to choose the right garlic clove vacuum packing machine?

Single-chamber garlic clove vacuum pack machine

Suitable for small-scale processors, start-up factories, or home workshops.

Downside: Lower production efficiency and requires frequent manual bag changes.

Double-chamber garlic clove vacuum pack machine

Ideal for medium to large-scale processing businesses.

Downside: Higher cost and slightly larger footprint.

Summary

If you are just starting or running a small-scale operation, a cost-effective single-chamber machine is recommended.

If you have stable orders and need to improve efficiency, the double-chamber model will save both time and labor in the long run.

Why choose Shuliy?

- Wide application: Suitable not only for garlic cloves, but also for vacuum packing various foods, fruits, vegetables, electronic products, and metal parts — one machine for multiple uses.

- No special vacuum bags needed: Compatible with smooth bags, zipper bags, aluminum foil bags, pure aluminum bags, printed bags, and handle bags.

- Smarter operation: Built-in smart control panel makes packing easier and more convenient.

- Durable vacuum pump: Equipped with a high-power pure copper industrial pump for stronger vacuum performance. Alloy heating wires ensure even heating and sealing. Pure copper transformer ensures long-lasting performance — machine lifespan can exceed 10 years.

- Low noise: Quiet operation protects the operator’s hearing.

- Sturdy body: Thickened stainless steel frame resists deformation and corrosion better than regular aluminum, and is easy to clean.

- Customizable options: Voltage, plug type, chamber depth, and material can all be customized.

- High-quality sealing strip: Fast, even heating for tight, strong, and clean seals.

- Mobile design with swivel casters: Durable rubber wheels rotate 360°, making it easy to move and reposition the machine.

- Safer power supply: Thick, aging-resistant power cord ensures safer electricity use.

Vacuum pump maintenance for garlic clove vacuum packer machine

In addition to daily cleaning and regular inspection of the sealing system, the vacuum pump is the most critical part of the

machine, as it directly affects the sealing performance. Proper maintenance is essential. Follow these steps:

Daily inspection

- Check if the vacuum pump oil level is within the normal range.

- If the oil is low, add the correct type of vacuum pump oil in time.

Replacing vacuum pump oil

- Turn off the machine and let it cool for about 10 minutes.

- Open the oil drain screw and fully drain the old oil. Dispose of the used oil properly.

- Clean the oil drain area with a dust-free cloth.

- Add new vacuum pump oil until the level reaches the middle of the oil sight glass.

- Start the pump and check for any oil leaks.

Replacing the oil and air filters

- Oil filter: Replace every 3–6 months, depending on the working environment.

- Air filter: Remove and clean or replace the filter regularly to avoid reduced performance.

Lubrication & Mechanical checks

- Bearing lubrication: Inspect bearing lubrication and add grease according to the manufacturer’s instructions.

- Belt & coupling Inspection: If the pump is belt-driven, check belt tension and wear. Adjust or replace as needed.

Operation monitoring

- Vacuum level check: Use a vacuum gauge regularly to test suction power. A drop in vacuum level may indicate worn seals or poor oil quality.

- Temperature monitoring: Keep an eye on the pump’s operating temperature. If overheating occurs, stop the machine and inspect it immediately.

Deep processing of garlic

In addition to vacuum packing machines, our factory also manufactures garlic cleaning machines and garlic peeling machines. Whether you’re planning to process garlic powder or produce garlic paste, we welcome all your inquiries about garlic processing equipment.

Hot Product

Garlic Peeling Machine

A garlic peeling machine is desinged to peel…

Garlic Clove Vacuum Packing Machine

Garlic clove vacuum packing machine with 20L copper-core…

Manual Garlic Harvesting Machine

Garlic harvesting machine helps farmers to harvest garlic…

Garlic Slicer Machine

Garlic slicer high performance, multi-functional, easy control of…

Garlic Dehydration Machine | Industrial Garlic Drying Oven

Garlic dehydration machine is a hot air circulation…

Ginger Garlic Paste Making Machine

Automatic ginger garlic paste making machine is widely…

Garlic Grading Machine

Commercial garlic grading machine use cylinders to classify…

Garlic Root Stem Cutting Machine

Garlic root stem cutting machine applies for cutting…

Garlic Powder Grinding Machine

The garlic powder grinding machine applies for grinding…