Can a garlic belt dryer be used to dry garlic slices?

Garlic belt dryers are commonly used for industrial drying of materials and can handle large batches of vegetables and fruits. But can they work for smaller items like garlic slices?

The answer is yes. They use multiple layers of mesh belts for even spreading and hot air circulation for uniform heating, quickly evaporating moisture while keeping the garlic slices’ color, nutrients, and flavor. The following article explains how belt dryers dry garlic slices.

Why is a garlic belt dryer suitable for drying garlic slices?

The reasons are:

- Suitable for sliced materials: Garlic slices are thin and light, easy to overlap. Multi-layer mesh belts can spread them evenly, ensuring uniform heating.

- Controllable temperature: Garlic slices are usually dried at 50–70°C to prevent yellowing and preserve nutrients and flavor. Belt dryers allow zone temperature control.

- Circulating hot air: Equipped with a hot air circulation system, it maintains stable airflow to remove moisture and improve drying efficiency quickly.

- Continuous production: Multi-layer belts allow continuous feeding and discharge, ideal for large-scale industrial drying of garlic slices.

- Good drying effect: Moisture content can be reduced to ≤5–8%, suitable for further grinding or long-term storage.

How does a garlic belt dryer machine dry garlic slices?

Similar to drying other vegetables, the process with a belt dryer generally includes: feeding → spreading → layered conveying → hot air drying → discharge.

Process

- Garlic Pre-treatment: Wash garlic cloves and slice them 2–3 mm thick. We also provide garlic slicers. Blanch in 80–90°C hot water for 1–2 minutes to prevent oxidation, then drain.

- Spreading: Garlic slices are evenly spread on the first layer of the metal mesh belt by a feeder, usually 2–4 cm thick.

- Layered Conveying & Drying: Slices move down through multiple belt layers while hot air blows from below or circulates, removing moisture from the material.

- Discharge: The finished garlic slices are white, crispy, with moisture content reduced to 5–8% (for reference).

Temperature Control (Reference)

- Initial: 55–60°C → Quickly remove surface moisture

- Middle: 60–65°C → Stable drying

- Final: 50–55°C → Low-temperature moisture removal to prevent yellowing

- Total drying time is about 4–6 hours. This temperature is for reference only, as each customer’s requirements for garlic slices may vary.

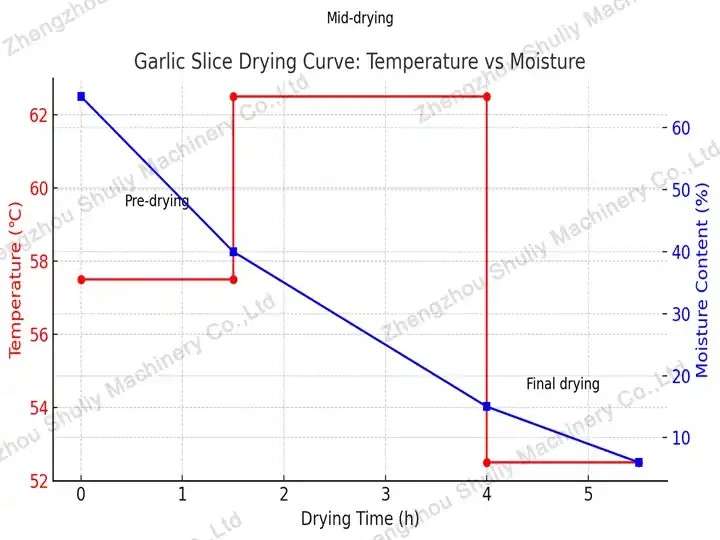

Temperature vs. moisture content comparison of garlic in a belt dryer

Garlic slice belt dryer process parameters table

| Stage | Temperature (℃) | Time (h) | Moisture Content Change |

|---|---|---|---|

| Pre-drying Stage | 55–60 | 1–2 | 65% → 40% |

| Middle Drying Stage | 60–65 | 2–3 | 40% → 15% |

| Low- Temp. Moisture Removal Stage | 50–55 | 1–2 | 15% → 5–8% |

| Total | / | 4–6 | Final ≤8% |

Why can a garlic belt dryer dry such small garlic slices?

Mesh Size and Material: The mesh should be small enough to prevent garlic slices from falling or getting stuck.

Recommended aperture: less than or equal to 4 mm, or use fine metal mesh/microporous stainless steel.

Suggested material: 304/316 stainless steel (acid-resistant and easy to clean).

Layered Belt Design: Layer spacing ≥ 60–80 mm to allow hot air penetration and prevent slices from sticking together.

Belt Tension and Flatness: Ensure no wrinkles or vibration to avoid garlic slices piling up or being sucked into the mesh.

Anti-Blocking/Anti-Migration Devices: Install guide plates, scrapers, or vibration devices at feeding and discharge points to keep material evenly spread and prevent accumulation.

Adjustable Incline and Speed: Slight incline (0–3°) helps discharge; belt speed should be variable (recommended 0.5–5 m/min or more detailed) to control residence time.

Model recommendation

| Model | SL-1.2-8 | SL-1.2-10 | SL-1.6-8 | SL-1.6-10 | SL-2-8 | SL-2-10 | SL-2-20 |

| Units | 4 | 5 | 4 | 5 | 4 | 5 | 10 |

| Belt width(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

| Drying length(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 |

| Material thickness(mm) | 10-80 | ||||||

| Service temperature(°C) | 50-140 | ||||||

| Steam pressure(Mpa) | 0.2-0.8 | ||||||

| Steam consumption(kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 |

| Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 |

| Drying intensity(kg/h) | 60-160 | 820-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 |

| Total power | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 |

| Length(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Width(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Height(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 |

| Total weight(kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 |

In addition, we also offer garlic drying rooms, garlic powder machines, and a complete range of garlic deep-processing equipment. You are welcome to contact us for drying solutions.