Garlic Drying Machine | Garlic Belt Dryer

The garlic drying machine, commonly known as a continuous food dehydrator or continuous belt dryer, can be used for dehydrating garlic slices. The dried garlic slices obtained can be ground into garlic powder for secondary processing.

This drying machine features fast drying speed and uniform drying performance, and it is widely used in the food, pharmaceutical, chemical, construction, and electronics industries.

The fully automatic garlic dryer is especially suitable for drying slice-, strip-, and granule-shaped materials with high moisture content that are sensitive to high temperatures, such as garlic slices and ginger slices.

Shuliy offers seven types of garlic drying machines, with drying lengths ranging from 8 to 20 meters to meet different production requirements. It can handle material thicknesses of 10–80 mm, ensuring uniform heating of garlic slices. The average drying time ranges from 0.2 to 3 hours, providing fast and efficient drying. Compared to conventional belt dryers, Shuliy’s machines save nearly 50% of the processing time.

Application scope of garlic drying machine

The automatic garlic dehydrator adopts a steel mesh conveyor design and can be widely used for drying and sterilizing various foods, including snacks, agricultural products, fish fillets, meat slices, bean products, instant noodles, fast food, tea, Chinese medicinal materials, fruits and vegetables, and seasoning powders. It is suitable for granular, sliced, and strip-shaped materials.

This machine is applied in fields such as food processing, agricultural product storage, seasoning production, healthcare, and international trade.

Garlic drying machine structural features

- Belt width: 1.2–2.2 m, drying length: 8–20 m, suitable for different production capacities.

- Material thickness: 10–80 mm, capable of drying a wide range of materials.

- Drying temperature: 50–140°C, steam pressure: 0.2–0.8 MPa.

- Drying capacity: 60–600 kg/h, with a short drying time of as little as 0.2 hours, ensuring fast and efficient operation.

- Steam consumption: 120–1200 kg/h, with high thermal efficiency.

- Total power: 11.4–36.8 kW, ensuring continuous high-intensity operation.

- Sturdy construction: machine weight 4500–14000 kg, suitable for long-term heavy-duty use.

- Made of high-strength steel, wear-resistant, pressure-resistant, and corrosion-resistant.

- Wide applications: suitable for drying wood, grains, pellets, biomass, and other materials, with precise control of temperature and drying intensity.

Structure of garlic drying machine

- Feeding system: Materials are evenly distributed onto the conveyor belt after feeding. Layer thickness adjustable: 10–80 mm.

- Conveyor belt system: Belt width: 1.2–2.2 m, adjustable speed, usually 3–5 layers. Made of food-grade stainless steel mesh for continuous feeding into the drying area.

- Drying chamber: Drying length: 8–20 m, working temperature: 50–140°C, steam pressure: 0.2–0.8 MPa. Materials are heated by hot air or steam for moisture evaporation.

- Heating system: Provides heat energy. Options: steam, hot air furnace, electric heating, or gas heating.

- Air circulation & exhaust system: Hot air circulation with moisture exhaust, keeping the chamber temperature stable. Air volume is adjustable, exhaust rate depends on the material’s moisture.

- Transmission & control system: Total power: 11.4–36.8 kW. Conveyor driven by motor, with PLC automatic control of temperature, speed, and humidity.

Technical Specification

| Model | SL-1.2-8 | SL-1.2-10 | SL-1.6-8 | SL-1.6-10 | SL-2-8 | SL-2-10 | SL-2-20 |

| Units | 4 | 5 | 4 | 5 | 4 | 5 | 10 |

| Belt width(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

| Drying length(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 |

| Material thickness(mm) | 10-80 | ||||||

| Service temperature(°C) | 50-140 | ||||||

| Steam pressure(Mpa) | 0.2-0.8 | ||||||

| Steam consumption(kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 |

| Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 |

| Drying intensity(kg/h) | 60-160 | 820-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 |

| Total power | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 |

| Length(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Width(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Height(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 |

| Total weight(kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 |

The above chart presents 7 of our garlic dehydrator machine models. The belt width and length can be customized according to the customers’ needs.

What are the outstanding advantages of an automatic garlic slice dryer?

- The garlic dehydrator machine can be a multi-layer mesh belt type, with automatic temperature control, automatic material spreading, and continuous production.

- All parts in contact with the product are made of food-grade stainless steel, ensuring hygienic drying.

- The garlic slice belt dryer is a newly developed type of equipment on the basis of the traditional belt dryer, with high energy utilization efficiency.

- Wide range of applications. The garlic slice dryer is suitable for the dehydration and drying of various regional and seasonal vegetables and fruits. Such as garlic slices, pumpkin, konjac, white radish, yam, bamboo shoots, etc.

- Available customization services to meet different processing needs according to different investments.

How does a garlic drying machine dry garlic slices?

Below, we will take our machine as an example to demonstrate the garlic slice drying process.

Breaks whole garlic bulbs into individual cloves.

Peels garlic cloves with a peeling rate of over 95%, without damaging the garlic.

Removes spoiled cloves and washes garlic in bulk using bubble cleaning.

Slice the garlic into pieces with a thickness of 2–3 mm.

Garlic drying machine

Dry the garlic slices for further processing or storage.

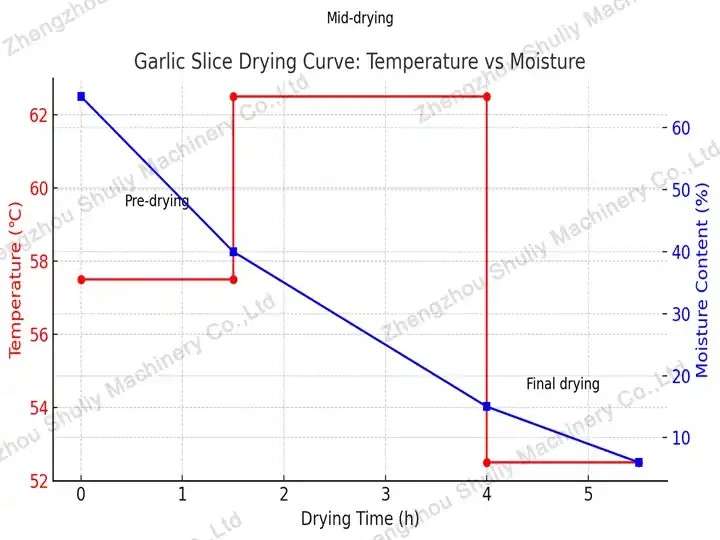

Temperature Control (Reference)

- Initial: 55–60°C → Quickly remove surface moisture

- Middle: 60–65°C → Stable drying

- Final: 50–55°C → Low-temperature moisture removal to prevent yellowing

Temperature control is related to the thickness of your material layer. The above is only a reference. The exact temperature and humidity should be adjusted according to your specific situation. If you are not sure how to set it up, we can provide support and help you complete the production

Another type of garlic dehydration machine

The following is another type of industrial garlic drying oven, with a number of trolleys and trays for batch drying.

If you want to know more about the garlic drying room, you can also contact us for more information.

Hot Product

Garlic Powder Packing Machine | Automatic Garlic Powder Packing Machine

This garlic powder packing machine is a fully…

Garlic Slicer Machine

Garlic slicer high performance, multi-functional, easy control of…

Garlic Slicer Machine

This garlic slicer machine is easy to operate…

Garlic peeling production line | Garlic processing machine

The garlic peeling production line is very practical…

Garlic Air Drying Machine

The garlic air drying machine is a highly…

Double belts garlic root concave cutting machine

The garlic concave root cutting machine removes the…

Manual Garlic Harvesting Machine

Garlic harvesting machine helps farmers to harvest garlic…

Garlic powder production line

The garlic powder production line mainly includes garlic…

Garlic Drying Machine | Garlic Belt Dryer

Garlic dehydrator machine is commonly known as a…